Wednesday, January 10, 2024

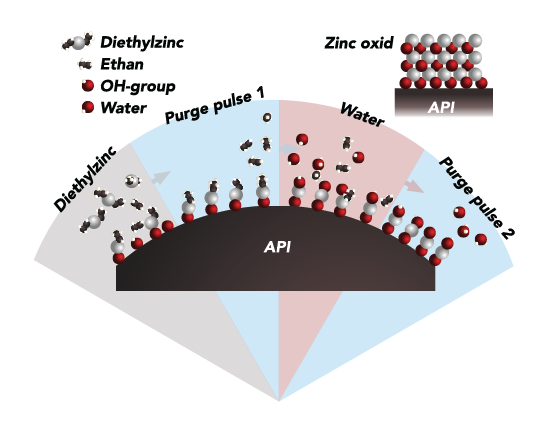

NCD supplied repeated ALD equipment for special protective coating

Wednesday, December 27, 2023

Exploring Ultrathin Solar Cells with Professor Carl Hägglund: A Journey from Stanford's ALD Techniques to Plasmonic Solar Cell Optimization

Wednesday, December 20, 2023

Enhancing Thin Film Deposition with Plasma-Activated Water: A Novel Approach in Atomic Layer Deposition

The research article "Novel Energetic Co-Reactant for Thermal Oxide Atomic Layer Deposition: The Impact of Plasma-Activated Water on Al2O3 Film Growth" presents a groundbreaking study on the use of plasma-activated water (PAW) in the atomic layer deposition (ALD) of Al2O3 thin films. This study offers significant insights into the potential advantages of using PAW over traditional water in thin film deposition processes.

One of the key findings of this research is the enhanced Growth Per Cycle (GPC) when using PAW as a co-reactant. The study found that PAW led to an increase in GPC of up to 16.4% compared to deionized (DI) water. This enhancement is attributed to the reactive oxygen species present in PAW, such as H2O2 and O3, which are believed to activate substrate sites more effectively, thereby improving both the GPC and the overall quality of the films.

The study also delves into the chemical reactivity of PAW, noting significant changes in its physicochemical properties upon activation. These changes include a decrease in pH, indicating increased acidity, as well as increases in oxidation-reduction potential (ORP), conductivity, and total dissolved solids (TDS). Additionally, the concentration of reactive species like H2O2, NO2−, NO3−, HNO2, and O3 was found to be higher in PAW.

The improved film quality achieved with PAW is another highlight of the study. Films grown using PAW, especially with PAW at a pH of 3.1, displayed a near-stoichiometric O/Al ratio, reduced carbon content, and an expanded bandgap. These characteristics are indicative of a superior film quality compared to those grown using DI water.

Furthermore, the study suggests that a comprehensive understanding of PAW's role in ALD necessitates further investigations. These investigations should explore different temperatures, metal precursors, and PAWs generated by alternate non-thermal plasmas.

The term “PAW-ALD” has been proposed to describe this enhanced variant of the ALD process that incorporates plasma-activated water. This new descriptor highlights the unique approach and potential benefits of using PAW in thin film deposition processes.

Finally, the potential applications of this research are significant. The use of PAW in ALD could mirror the gains observed in plasma-enhanced atomic layer deposition (PEALD) processes that use oxygen plasma, indicating its potential industrial relevance.

Source:

Announcement: Webinar on ALD and MLD Techniques for Advanced Functional Materials

Join us for an enlightening webinar on Atomic Layer Deposition (ALD) and Molecular Layer Deposition (MLD), showcasing their combined prowess in the creation of novel inorganic-organic materials. This event is an excellent opportunity for those interested in advanced material sciences and engineering.

Date and Time: Tuesday, 16th of January, 2024 at 14:00 CET

Duration: 45 minutes

This session will provide a comprehensive overview of ALD and MLD, contrasting them with traditional solution-based methods. We will delve into how these techniques enable the formation of high-quality thin films, crucial for practical applications in areas such as optical data storage and wearable energy harvesting devices.

Key Highlights:

- An introduction to ALD-MLD techniques.

- Exploration of state-of-the-art inorganic-organic thin films, including photoactive ferrimagnetic and thermoelectric hybrid thin films.

- Discussion on technical challenges with organic precursors and solutions for industrial-scale application.

Guest Speaker: Topias Jussila, Doctoral Researcher, Aalto University

Topias Jussila is a promising PhD student at the Department of Chemistry and Materials Science, Aalto University, Finland. With a background in Chemistry and Functional Materials, his current research focuses on the development of novel thin film materials using ALD and MLD, particularly in the realm of iron-based materials.

Don't miss this opportunity to gain insights into the cutting-edge world of thin film materials and their applications. Register today to secure your spot!

For more information and registration, visit Atomic layer deposition (ALD) and molecular layer deposition (MLD) together present an elegant technique for the deposition of novel inorganic-organic materials. (picosun.com)

Saturday, December 2, 2023

Introducing ALD to the Semiconductor Industry with Suvi Haukka – ALD Stories Ep. 29

Friday, December 1, 2023

ASD2024: Uniting the World of Area Selective Deposition in Historic Old Montreal

Announcement for ASD2024 Workshop

Dates: April 15-16, 2024

Location: Old Montreal, Canada

Welcome and bienvenue to the exciting Area Selective Deposition (ASD) workshop to be held in the picturesque Old Montreal. This two-day event, scheduled for April 15 and 16, offers an enriching platform for both academic and industry professionals to exchange groundbreaking ideas in the field of ASD.

Special Sessions:

1. Pre-Workshop Tutorial: A comprehensive half-day tutorial on April 14 (Sunday afternoon). Note: This session requires an additional fee.

2. Atomic Layer Processing Showcase: A half-day event on April 17 (Wednesday morning), highlighting Canada's advancements in atomic layer processing. This session is included in the conference fee.

Conference Venues:

- Hotel Place d'Armes (55 Rue Saint-Jacques): Main sessions and lunches on Monday and Tuesday will be hosted here. This 4-star hotel is conveniently located near a metro stop.

- Hotel Nelligan (106 Saint-Paul St W): A 4-star boutique hotel, the venue for the opening mixer on Sunday evening and the poster session on Monday evening.

Workshop Highlights:

- Single session format over two days featuring invited and contributed talks.

- A panel discussion focusing on the industrial and academic communication of ASD.

- Networking opportunities with leading experts and peers.

Explore Montreal:

Participants are encouraged to experience the charm of Old Montreal, known for its vibrant restaurants, bars, shopping venues, and historical sites like the Notre Dame Basilica and the port. For sports enthusiasts, the Circuit Gilles Villeneuve offers a unique opportunity for running and cycling.

Organizers:

- Prof. Sean Barry, Carleton University

- Prof. Paul Ragogna, Western University

Scientific Committee:

- Adrie Mackus, Eindhoven University of Technology

- Anjana Devi, Ruhr University Bochum

- Annelies Delabie, IMEC

- Anuja DaSilva, Lam Research

- Dennis Hausmann, Lam Research

- Erwin Kessels, Eindhoven University of Technology

- Gregory Parsons, North Carolina State University

- Han-Bo-Ram Lee, Incheon National University

- Ishwar Singh, IBM

- Keyvan Kashefi, Applied Materials

- Kristen Colwell, Intel

- Mark Saly, Applied Materials

- Marko Tuominen, ASM

- Ralf Tonner-Zech, Wilhelm-Ostwald-Institute für Physikalische und Theoretische Chemie

- Ravi Kanjolia, EMD Electronics

- Robert Clark, TEL

- Sang Hoon Ahn, Samsung Electronics

- Seung Wook Ryu, SK hynix

- Stacey F. Bent, Stanford University

Contact Information:

Monday, November 27, 2023

Congratulations to Jusung Engineering on 30 Years of Pioneering Innovation and Market Leadership in ALD, Semiconductor, Display, and Solar Technologies!

Jusung Engineering, celebrating its 30th anniversary, is a leader in semiconductors, displays, and solar equipment. Founded in 1993, the company has seen considerable growth through innovation, achieving record sales and operating profits last year. It specializes in semiconductor equipment for memory and non-memory sectors, leveraging advanced ALD technology. In displays, Jusung is diversifying equipment for various panel sizes, while in solar, it's innovating with high-efficiency solar cells. The company is investing in future growth, with new R&D and manufacturing facilities, focusing on technological independence. It holds over 3,000 patents, with 65% of its workforce in R&D, investing 15-20% of sales in technology development. The CEO attributes their success to relentless innovation and a unique path, with plans to maintain leadership in future technologies and expand into global markets. Despite recent challenges, Jusung remains optimistic, prioritizing innovation and market creation.

The Jusung Engineering headquarters in Gwangju, Korea 출처 : Businesskorea (https://www.businesskorea.co.kr)

Fullarticle and interview:

Thursday, November 23, 2023

AI-Driven Chip Demand Spurs Optimism in Semiconductor Industry; Analyst Upgrades Key Players with Bullish Price Targets

- Lam Research: $800 - now $717

- ASM International: €545 - now $459

- KLA: $550 - now $554

- Applied Materials: $175 - now $149

Wednesday, November 22, 2023

SEMICON Europa 2023: A Deep Dive into ALD Technology for Wafer Fab Equipment in the More-than-Moore Era

Last week at SEMICON Europa, at the ALD Tech Day Organized by Beneq, Yole Group presented a comprehensive analysis on ALD technology for More-than-Moore (MtM) devices, focusing on its impact and future in the wafer fab equipment market. The presentation titled "Atomic Layer Deposition for More-than-Moore Devices in a Perspective of the Wafer Fab Equipment Market" offered valuable insights into the current trends and future directions of this pivotal technology.

The Growing Importance of ≤200 mm Wafers

A focal point of the discussion was the ≤200 mm wafer size, a segment that remains crucial in the semiconductor industry despite the surge in larger wafer sizes. The presentation highlighted the market size, chipmaker revenue, and capacity expansion specifically for this category. It emphasized that while the industry continues to evolve technologically, the demand for ≤200 mm wafers remains robust, accounting for a significant portion of the market.

Semiconductor Device Revenue Projections

Yole Group presented a detailed forecast for semiconductor device revenue, segmenting it by device type. They projected a CAGR of approximately 4.5%, expecting the overall market to reach around $850 billion by 2030. Within this, MtM devices are anticipated to contribute significantly, estimated at about $270 billion, indicating the growing relevance of these devices in the semiconductor landscape.

Capital Expenditure Trends and ALD Market Dynamics

The presentation also shed light on the capital expenditure (CapEx) trends in the industry, particularly for 200 mm wafer processing. With CapEx projected to increase to 17% of the revenue by 2025, a subsequent trend towards more sustainable levels by 2028 was also anticipated. This trend underscores the expanding market and the need for more Wafer Fab Equipment (WFE), presenting a substantial opportunity for the growth of ALD technologies.

Atomic Layer Deposition: Meeting Industry Needs

The analysis delved deeply into the ALD market, discussing how this technology is evolving to meet the changing demands of the semiconductor industry. It was pointed out that ALD technology is not just adapting but also driving significant advancements, particularly in the context of MtM devices.

From the presentation by Yole Group focuses on the use of ALD in power devices, emphasizing its role in enhancing device performance through precise interface control. The need for specialized ALD equipment, capable of handling multiple processes and materials, including thermal and plasma ALD with various precursors. ALD applications are found in in Silicon Carbide (SiC) and Gallium Nitride (GaN) devices, covering aspects like passivation, substrate creation, and buffer layers. While ALD is still in R&D for GaN High Electron Mobility Transistors (HEMT), it is already being used for SiC Trench and Planar MOSFETs in encapsulation and gate dielectrics, signaling its growing importance in semiconductor manufacturing.

Industry Challenges and Opportunities

The challenges and opportunities within the semiconductor industry were a crucial part of the discussion. The presentation addressed the current supply chain dynamics, technological innovations, and market trends that are shaping the adoption and development of ALD technology.

Conclusion

The presentation at SEMICON Europa provided a lucid and detailed perspective on the ALD technology in the context of the wafer fab equipment market. With a focus on ≤200 mm wafer size, it painted a comprehensive picture of the current market scenarios, future trends, and the pivotal role of ALD technology in shaping the future of semiconductor manufacturing. As the industry continues to evolve, the insights from this presentation will undoubtedly influence strategic decisions and technological advancements in the semiconductor sector.

Source: ALD TECHDAY 2023 powered by Beneq (yolegroup.com)

Presentation shared with the attendees

AIXTRON's G10-GaN System Empowers BelGaN's Expansion into the Growing GaN Semiconductor Market

The article discusses AIXTRON's support for BelGaN in expanding its Gallium Nitride (GaN) business through the new G10-GaN system. AIXTRON SE, a semiconductor company, is enabling BelGaN, a leading GaN automotive-qualified semiconductor foundry in Europe, to enter the growing GaN market and boost GaN technology innovation. BelGaN plans to use AIXTRON's G10-GaN, which offers top performance, a compact design, and low cost per wafer, starting with an 8x150mm configuration, to be delivered to BelGaN's production site in Oudenaarde, Belgium, by the end of 2023. This system will later evolve to support 5x200mm.

AIXTRON's G10-GaN System Empowers BelGaN's Expansion into the Growing GaN Semiconductor Market

BelGaN aims to expand its power chip range with voltage ratings from 40V to 1200V, utilizing GaN-on-Si, GaN on SOI, and new GaN-on-engineered substrates, focusing on high performance, automotive quality, reliability, high yield, and low costs. The G10-GaN will enable innovations in device architectures and improvements in performance, yield, and quality, reducing the cost of GaN products. This advancement is expected to drive growth in e-mobility, datacom, energy conversion, and contribute to a carbon-neutral society.

The G10-GaN epitaxy system is a highly efficient, productive, and cost-effective solution for GaN power and RF applications, combining single wafer performance with the economy of batch processing.

Dr. Marnix Tack of BelGaN praised the productivity, uniformity, and low cost of ownership of the G10-GaN, while Dr. Felix Grawert of AIXTRON expressed pride in BelGaN's choice of their technology. The G10-GaN, building on the G5+ C platform, offers double the productivity per cleanroom area, better material uniformities, and over 25% lower cost of ownership compared to other market equipment, making it a competitive choice for AIXTRON's customers. This MOCVD system is fully automated and designed for silicon fabs, marking a significant technological step in the semiconductor industry.

G10 GaN Performance (www.aixtron.com)

The G10-GaN by AIXTRON is a state-of-the-art deposition system for 150/200 mm GaN epitaxy, designed for GaN power and RF applications. It features a compact cluster design with three process chambers, reducing the footprint by 50% while maximizing wafer yield per square meter. This system significantly improves device yield with a threefold increase in on-wafer uniformity and maintains low particle levels, enhancing overall quality and consistency.

Cost-effectiveness is a key attribute, with the G10-GaN offering more than 25% lower epitaxial cost per wafer compared to other platforms. It incorporates Planetary Reactor® technology for high wafer yield and uniformity. The system's productivity is marked by over 90% equipment uptime and highest throughput per fab area, supported by features like fully automated wafer handling and advanced temperature control.

The G10-GaN ensures easy maintenance and operation with features like automated chamber cleaning and predictive functionalities. It's compatible with existing AIX G5+ C tools, facilitating seamless process transfers. Overall, the G10-GaN epitaxy system combines efficiency, cost-effectiveness, and advanced technology, making it an optimal choice for semiconductor manufacturing in the GaN sector.

Market opportunity for GaN for MOCVD and ALD

Friday, November 17, 2023

Forge Nano Unveils Plans for U.S.-Based Lithium-Ion Battery Gigafactory in North Carolina, Set to Launch in 2026

Forge Nano, Inc. has announced its venture into lithium-ion battery manufacturing with the creation of Forge Battery. The company plans to establish a Gigafactory in Raleigh, North Carolina, targeting defense, aerospace, and specialty electric vehicle markets. With an initial investment of over $165M, the facility, operational by 2026, will produce batteries utilizing Forge Nano’s Atomic Armor surface technology, enhancing energy density, safety, and lifespan.

This technology is expected to surpass existing lithium-ion cells in performance. The North Carolina facility, benefiting from state incentives and a Job Development Investment Grant, promises significant economic benefits, including hundreds of high-paying jobs and substantial tax revenue to support local communities. The groundbreaking event is scheduled for the first half of 2024.

- Forge Nano has raised $81.54M over 10 rounds.

- Forge Nano's latest funding round was a Series C for on May 30, 2023.

Source:

Forge Nano Stock Price, Funding, Valuation, Revenue & Financial Statements (cbinsights.com)

Tuesday, November 7, 2023

Molybdenum: The New Frontier in Semiconductor Metallization according to Lam Research

Friday, November 3, 2023

Nanexa AB Concludes Rights Issue on Nasdaq First North Growth

Nanexa AB's rights issue, aimed at raising SEK 121m, concluded with a 34.7% subscription rate using rights and without. The company will utilize guarantee commitments for the remaining 27.1%. The rights issue, announced on September 21 with backing for 62% of the total, resulted in 33.5% of shares subscribed with rights and 1.2% without. The capital raised before transaction costs will be SEK 75m. Trading in BTAs will occur until registration is completed around week 45, 2023, with the new shares expected to trade on Nasdaq First North Growth by week 46, 2023.

Nanexa, founded in 2007, has evolved from working with Atomic Layer Deposition (ALD) technology for various applications to focusing on the pharmaceutical sector with its proprietary PharmaShell® system. PharmaShell® positions Nanexa in the burgeoning drug delivery market with a system that allows high-precision, long-acting injectable drug products. The company is developing its own products and also partners with multiple pharmaceutical firms, including AstraZeneca, leveraging the unique capabilities of its ALD-based technology to enhance drug delivery.

ALD Adaptation Promises Advances in Solid-State Battery Development

Monday, October 23, 2023

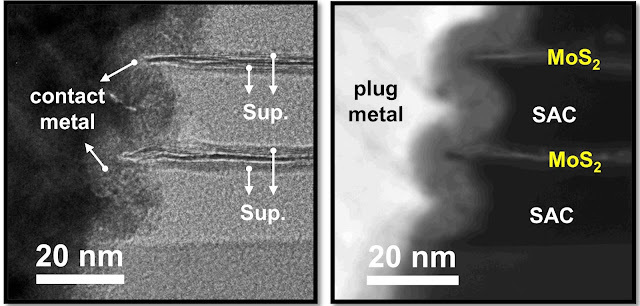

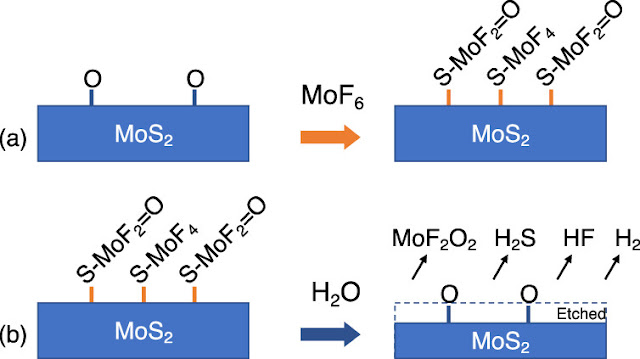

TSMC To Report Breakthrough in NMOS Nanosheets Using Ultra-Thin MoS2 Channels at IEDM 2023

Saturday, October 21, 2023

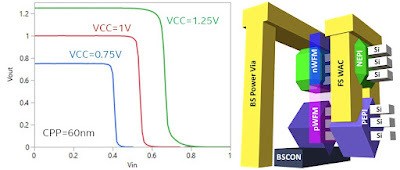

Intel Unveils Breakthrough 3D CFET Design at IEDM: Setting the Stage for Next-Gen Compact and Efficient Electronics

Intel researchers developed a 3D monolithic CFET device* with 3 n-FET nanoribbons atop 3 p-FET nanoribbons, separated by 30 nm gap. This industry-first device enabled the creation of functional inverters at a 60 nm gate pitch. Notably, it incorporated vertically stacked dual-Source/Drain epitaxy, dual metal work function gate stacks, and backside power delivery with direct device contacts. They also introduced a nanoribbon "depopulation" method for varying n-MOS/p-MOS device numbers. This research advances the understanding of CFET scalability for logic and SRAM applications and highlights key process enablers. The paper will be presented at the upcoming IEDM conference in San Francisco.

Comment: The stacked CMOS inverter at a 60 nm gate pitch represents an advancement in semiconductor design, allowing for denser circuits. The 60 nm distance between gates indicates a highly miniaturized design. Power vias provide vertical power connections to different layers, while direct backside device contacts enhance efficiency and heat dissipation. This development offers a glimpse into the future electronic devices being more compact, efficient, and high-performing than deploying "planar" designs in one layer like the FinFETs and GAA-FETs of today.

ALD plays a key role in manufacturing 3D monolithic CFET devices by assisting in crafting the architecture and providing atomically precise and even thin film layers at small scales. ALD ensures even coverage, which is important for 3D designs, especially on vertical areas and inside deep gaps. It's used to put down important materials in transistor gate stacks (High-k/Metal Gates or HKMG), as well as barrier and seed layers. ALD also helps in doping (SSD - solid state doping), which changes how semiconductors behave, and in creating spacers, important for separating and defining parts of transistors. In brief, ALD helps improve the CFET design and its overall performance.

* A 3D monolithic CFET device combines three-dimensional stacking and the Complementary Field-Effect Transistor (CFET) design within a single semiconductor structure. This approach vertically integrates both n-type and p-type transistors on the same substrate, promoting tighter integration and reduced interconnect delays. By leveraging the complementary operation of CFET and the benefits of 3D stacking, the device aims to enhance performance, miniaturization, and efficiency in semiconductor technology.

%20(1).png)