Strem Chemicals

is a well-established (since 1964) supplier of ALD and CVD precursors for both

R&D and industrial applications. Many of their compounds are also available

in electronic grade suitable for semiconductor applications. The full range of

their ALD and CVD precursors can be found in their famous catalog available as

a hard copy or on line [LINK]. Amongst the

wide range of precursors, the platinum precursors and especially the (trimethyl)methyl-cyclopentadienylplatinum(IV)

- MeCpPtMe3 has proven popular for a wide range of ALD and CVD applications.

Platinum and

platinum-rich alloys are naturally occurring and have been known for a long

time since it is often found as native platinum. It occurs naturally in the

sands of rivers in South America and it was first used by pre-Columbian natives

to produce artifacts. Later in 16th century the Spaniards named the metal

"platina," or little silver, when they first encountered it in

Colombia. They regarded platinum as an

unwanted impurity in the silver they were mining and it was not until 1748 that

platinum was properly reported by Antonio de Ulloa y de la Torre-Giral, a

Spanish general of the navy, explorer, scientist, author, astronomer and

colonial administrator.

Since the

platinum has become known and used because of the outstanding catalytic properties,

which it has in common with the other of the six platinum group metals (PGM) –

iridium, osmium, palladium, platinum, rhodium, and ruthenium. In

addition, platinum's wear and tarnish resistance characteristics are well

suited for making fine jewelry. Other distinctive properties

include:

- high resistance to chemical attack

- excellent high-temperature characteristics

- stable electrical properties.

Because of all

these extraordinary properties the PGMs have been exploited for a wide range of

industrial applications. Platinum, platinum alloys, and iridium are

used as crucible materials for the growth of single crystals, especially

oxides. The chemical industry uses a significant amount of either

platinum or a platinum-rhodium alloy catalyst to catalyze the partial oxidation

of ammonia to yield nitric oxide, which is the raw material for fertilizers,

explosives, and nitric acid.

In recent years,

a number of PGMs have become important as catalysts in synthetic organic

chemistry. Platinum supported catalysts are used in the refining of crude

oil, reforming, and other processes used in the production of high-octane

gasoline and aromatic compounds for the petrochemical

industry. Since 1979, the automotive industry has emerged as the number

one consumer of PGMs. Palladium, platinum, and rhodium have been

used as oxidation catalyst in catalytic converters to treat automobile exhaust

emissions. A wide range of PGM alloy compositions are used in

low-voltage and low-energy contacts, thick- and thin-film circuits,

thermocouples and furnace components, and electrodes.

It was not until

the early 2000 that the platinum and the other PGMs became available as a ALD

processes and here below is a summary of the most important fundamental discoveries

of platinum ALD.

Thermal ALD of high quality platinum films

It all started

with thermal ALD of platinum and ruthenium in Helsinki Finland at the famous

Laboratory for Inorganic Chemistry headed by Prof. Markku Leskelä and Prof.

Mikko Ritala. Here it was found that high quality platinum films can be grown

by thermal ALD from MeCpPtMe3. According to the first publications

by Titta Aaltonen (summarized in her PhD Thesis University of Helsinki: LINK) the

films had strong (111) orientation even down to the lowest growth temperatures.

Except for discovering the secrets of thermal ALD of noble metals (Ru, Ir Pt,

Pd) Titta Aaltonen made groundbreaking studies of their ALD growth mechanism with O2 as the

co-reactant. At first it may seem strange that O2, or in her case also

laboratory air or pressured air, could be used to grow high quality noble metal

films. Titta Aaltonen found that adsorbed oxygen atoms react with the ligands

of the noble metal precursor during the metal precursor pulse. Unreacted ligand

species that remained on the surface after the metal precursor pulse react with

oxygen during the following oxygen pulse. The main reaction by-products

detected during the both reaction steps were water and carbon dioxide. For

detailed studies of the ruthenium process using RuCp2 it has been

concluded that active oxygen that dissolves in the upper most monolayers of the

growing noble metal film may be behind the nucleation and growth mechanism of

the next “ALD monolayer”.

The growth rates

of the platinum films grown at 300 °C from MeCpPtMe3 was reported at

about 0.5 Å/cycle both when air and pure oxygen were used as oxygen sources and

a 50-nm film grown at 300 °C had a resistivity of 13 μΩcm, which is close to

bulk value for platinum. It was also found that the difference between air and

O2 co-reactant was in how the films adhered to the substrate. The films grown

with air as the oxygen source did not pass the famous scotch tape test, while

the films grown with pure oxygen passed the tape test.

Besides having

such a beautiful ALD mechanism with such a simple co-reactant as air or O2,

one additional very big advantage with the MeCpPtMe3 precursor is

that can be vaporized at room temperature, just slightly below its melting

point of 30 °C since the vapor pressure of MeCpPtMe3 at room

temperature is high enough for delivery into an ALD process chamber. If you

need a bit more precursor flow for larger batch type reactors or applications

with relying on high surface area you can melt the precursor in a standard

stainless steel ampule or bubbler with carrier gas dip tube to enhance the flow

further.

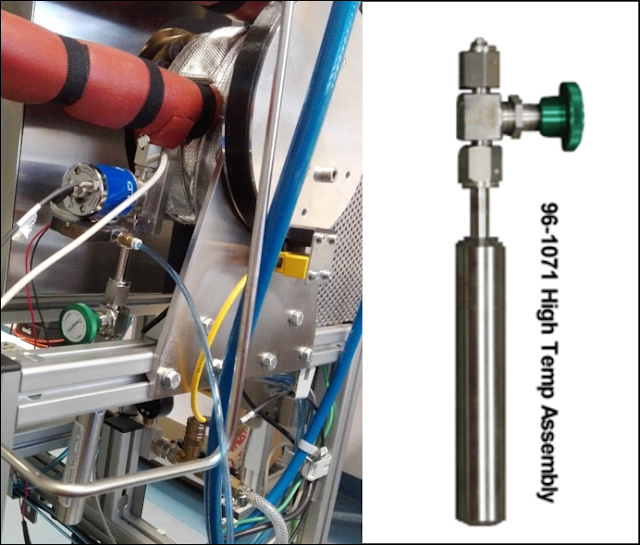

A hook up of MeCpPtMe3

precursor supplied in a Strem

Swagelock ALD/CVD cylinder via a standard Swagelock ALD-valve as close as

possible to a thermal horizontal low pressure ALD/CVD reactor (at Fraunhofer

IKTS, Dresden, Germany, LINK) to

save valuable platinum precursor (LINK) In

order to enhance the precursor flow the installation can be wrapped with heater

tape and heated to 30-50 °C.

Plasma ALD of platinum films

Some years later,

Harm Knoops (now TU Eindhoven/Oxford Instruments) and co-workers published

extensive results in a benchmarking study in 2009 [LINK]

using MeCpPtMe3 precursor in a plasma ALD reactor with a remote ICP

O2 Plasma. Here they proved that by the plasma enhanced ALD process

(PEALD), the growth temperature could be reduced considerably to as low as 100

°C for both platinum metal and platinum oxide film growth and it was possible

to switch between the two growth modes by adding a H2 step to grow

metallic films. More recently, the same group reported platinum ALD at room

temperature on polymer, textile, and paper substrates [LINK]. By

tuning the dosing of MeCpPtMe3, O2 plasma exposure, and H2

gas or H2 plasma exposure high-quality platinum films with a

resistivity of 18–24 μΩ cm were obtained.

Growth of platinum nanoparticles by ALD

Most recently

Prof. Ruud van Ommen (TU Delft) published their detailed study [LINK] on

how to control and grow platinum nanoparticles by ALD, again using the

MeCpPtMe3 precursor.

They showed that

the nanoparticle aggregation takes place during the oxygen half-reaction and

that the mobility of the nanoparticles exhibits a size- and

temperature-dependent scaling and that ALD-like precision over the nanoparticle

size requires low deposition temperatures (< 100 °C).

Industrial applications for platinum ALD

Since early 2000

platinum ALD has been considered in parallel to ruthenium and evaluated

multiple times by academia and industry for the use in a number of

microelectronic applications including:

- Electrodes for DRAM high-k capacitors

- Transistor Source/Drain contacts with nickel Ni(Pt)Si

- DRAM buried Word Lines and Bit Lines

- Local interconnects as Cu seed layer or complete fill replacing tungsten

The semiconductor

industry is very sensitive for raw material pricing and therefore introduction

of platinum so far has mainly been using PVD in the case of Ni(Pt)Si source

drain contact and for the other applications mentioned above there has been no

reports of high volume manufacturing. Meanwhile, ruthenium on the other hand

had have some success for hard disk reader heads and is now considered for

local interconnects for technologies at 5 nm or below.

One of the

biggest industrial applications for the MeCpPtMe3 precursor today is for E-beam

direct write repair of photo lithographic masks for both Immersion and EUV

lithography and making direct chip level contacts for electrical

characterization in FIB-SEM.

Current research and development on using platinum ALD or CVD as deposition method focuses on:

- Nanobatteries using platinum contacts and electrodes

- Supercapacitors using platinum electrodes

- Nanoparticle catalysis

- Core shell nanoparticles (nanoparticles covered by an ultra-thin platinum layer)

- As contacts to III/V nanowire and 2D materials devices

- Electrodes and contacts in printed flexible electronics

- 3D Nanoprinting via laser-assisted electron beam induced deposition

The main issue to

overcome for any successful industrial scale up of platinum is to minimize the

use of bulk platinum and use ultra-thin layers and if bulk material is need use

either substrates with a very large surface or coated low cost particles.

Eventually, for all applications, platinum being a noble metal all of the by-products

of precursor or coated parts has to be recaptured and recycled.

In the case of

automotive catalyst support such PGM recycling plants are operational since

long time (e.g. operated by BASF and Umicore). For the ruthenium introduction

in the semiconductor device manufacturing, several companies have reported

development of recapture and recycling methods (e.g. Praxair, Tokyo Electron

and Tanaka) and we can assume that these can also be adapted for platinum

precursor recapture and recycling. Finally, to put things in perspective, the

USGS reported that about 110,000 kilograms of platinum, palladium, and rhodium

was recovered globally from new and old scrap in 2017 and they estimate the

world resources of PGMs to a total more than 100 million kilograms. The largest

reserves are in the Bushveld Complex in South Africa.

References

ALD of platinum from MeCpPtMe3 and Air and the ALD

nobel metal / oxygen reaction mechanism: T. Aaltonen, A.

Rahtu, M. Ritala, and M. Leskelä, Reaction Mechanism Studies on Atomic Layer

Deposition of Ruthenium and Platinum, Electrochem. Solid-State Lett., 6 (2003)

C130–C133. [LINK]

ALD of platinum from MeCpPtMe3 and O2 : T.

Aaltonen, M. Ritala, Y.-L. Tung, Y. Chi, K. Arstila, K. Meinander, and M.

Leskelä, Atomic Layer Deposition of Noble Metals: Exploration of the Low Limit

of the Deposition Temperature, J. Mater. Res., 19 (2004) 3353–3358. [LINK]

PEALD and thermal ALD of platinum films from MeCpPtMe3

: H. C. M. Knoopsa,

A. J. M. Mackus, M. E. Dondersa, M. C. M. van de Sanden, P. H. L. Notten, and

W. M. M. Kessels.

PEALD of platinum at room temperature : A.

J. M. Mackus, D. Garcia-Alonso, H. C. M. Knoops, A. A. Bol, and W. M. M.

Kessels, Room-Temperature Atomic Layer Deposition of Platinum, Chem. Mater.,

2013, 25 (9), pp 1769–1774 [LINK]

Platinum nanoparticle ALD growth : F. Grillo, H.

Van Bui, J. A. Moulijn, M. T. Kreutzer, and J. R. van Ommen, Understanding and

Controlling the Aggregative Growth of Platinum Nanoparticles in Atomic Layer

Deposition: An Avenue to Size Selection, J. Phys. Chem. Lett., 2017, 8 (5), pp

975–983 [LINK]

Facts about PGMs : Platinum-Group

Metals Statistics and Information (Platinum, Palladium, Rhodium, Ruthenium,

Osmium, and Iridium), U.S. Department of the Interior, U.S. Geological Survey [LINK]

MeCpPtMe3 product information and ordering from

Strem Chemicals (Item #: 78-1350):

Product Description:

(Trimethyl)methylcyclopentadienylplatinum(IV), 99%

CAS #: 94442-22-5

Safety Data Sheet: [LINK]

%20(1).png)