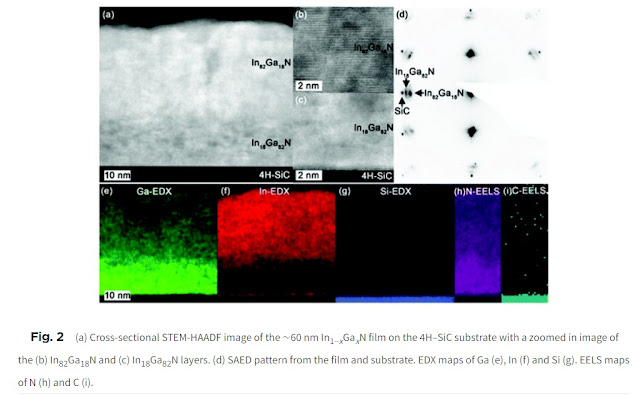

Polla Rouf of Pedersen Group in Linköping Sweden, just published an ALD approach to metastable In1−xGaxN with 0.1 < x < 0.5 based on solid In- and Ga-precursors that were co-sublimed into the deposition chamber in one pulse. A near In0.5Ga0.5N film with a bandgap value of 1.94 eV was achieved on a Si(100) substrate. Epitaxial In1−xGaxN(0002) was successfully grown directly on the 4H–SiC(0001) substrate.

I checked in with Prof. Pedersen on Twitter and this is gonna be one of the abstract submitted to AVS ALD 2022 in Ghent this summer.

- The sequential pulsing of the precursors in ALD presents a challenge to depositing a homogeneous ternary material as only one precursor can be pulsed into the reactor at a time.

- Ternary materials are therefore deposited by ALD as stacks of two binary materials. In1−xGaxN could therefore be deposited as layers of InN and GaN in an ABAB⋯CBCB… super-cycle approach where A and C are In- and Ga-precursors, respectively, and B is the N-reactant. By varying the number of cycles for each binary material, the overall composition of the ternary material can be tuned.

- This approach relies on diffusion of the two binary materials to form a homogeneous ternary phase. Otherwise, a multilayer of InN/GaN is obtained. This ALD approach has been used to obtain In1−xGaxN with x ranging from 0.15–0.85 using trimethylindium and trimethylgallium.

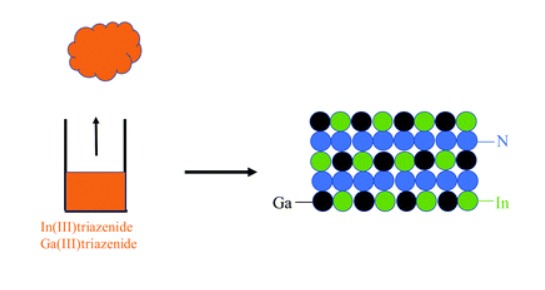

- Here, an alternative method to depositing ternary materials by introducing both metal precursors with a single pulse. This renders mixing of the metals in both the growth direction and in the growth plane. This was achieved by mixing and co-subliming two solid metal precursors into the ALD chamber.

Open source article: In0.5Ga0.5N layers by atomic layer deposition - Journal of Materials Chemistry C (RSC Publishing)

%20(1).png)