The traditional methods dependent on fossil fuels to reduce silicon dioxide are being challenged by KTH and Green14's reactor, which has a fossil-free process using hydrogen-based plasma reduction. This high-temperature plasma, created from a combination of hydrogen and argon gas, emits water vapor instead of carbon dioxide and has silane as another byproduct, used for producing silicon anodes for lithium-ion batteries.

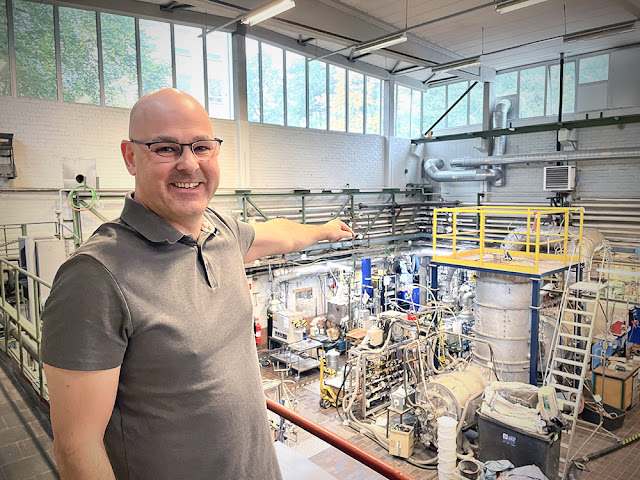

KTH (Royal Institute of Technology in Stockholm, Sweden) is challenging China's silicon production. A portrait depicts researcher Björn Glaser in a lab hall, pointing out the location where a reactor will be constructed. This seven-meter-tall reactor, being developed in collaboration with startup company Green14, aims to produce green silicon at KTH and challenge Asia's dominance in the solar cell silicon market.

Björn Glaser, researcher and project manager, points out the location in the so-called furnace hall where a reactor will be built. (Photo: Anna Gullers)

In a few months, the new reactor will begin construction at the Department of Materials Science, reaching the ceiling of the grand furnace hall, becoming KTH's largest pilot facility. The researchers aim to develop a process for silicon production that's faster and more environmentally friendly than previous methods.

Using 3,000-degree hydrogen plasma, the reactor will convert silicon dioxide to silicon, crucial for manufacturing solar cells and semiconductors. Unlike traditional methods that rely on fossil fuels, this process with hydrogen plasma emits water vapor instead of carbon dioxide.

The primary goal is to produce silicon suitable for solar cells, a market dominated by Asia, particularly China. Björn Glaser, a lecturer and expert in high-temperature metallurgical experiments, believes this could be a game-changer, potentially bringing Europe back into competition.

Green14, the startup behind the initiative, will own and operate the facility, with Björn Glaser and Adam Podgorski, an Australian chemist and CEO of Green14, working closely together. If successful, Green14 plans to build a larger facility in northern Sweden. However, a significant challenge is ensuring safety due to the combination of extremely high temperatures and hydrogen gas.

Björn Glaser expresses that the project not only provides good PR for KTH but also offers students a unique opportunity to engage in groundbreaking research. If successful, the process could revolutionize how other metals, like copper, titanium, and vanadium, are produced, reducing their carbon footprints and making them cheaper to manufacture.

About GREEN14

GREEN14 is a pioneering technology company committed to developing innovative solutions for a sustainable future. With a focus on renewable energy, GREEN14 is revolutionizing the production of solar grade silicon through its groundbreaking quartz reduction process. By combining cutting-edge technology with a commitment to environmental stewardship, GREEN14 is driving the transition to a low-carbon economy and paving the way for a cleaner, brighter future.

Sources:

KTH utmanar Kinas kiselproduktion | KTH

General 2 — Green14

%20(1).png)