I was, as usual, searching for any news about ALD and came across this press release from Liquid X. Funny that anything on atomic level can be regarded as disruptive these days - and yes I am proud of the headline, which originally red "ALD - More than 41 years of descriptiveness"

"Liquid X Printed Metals®, Inc. is a technology company headquartered in Pittsburgh, Pennsylvania that manufactures functional metallic inks. Liquid X® inks are considered disruptive in that their technology is on the atomic level. This provides processing advantages and achieves better metal film properties than other metallic inks that feature nanoparticles and metal flakes."

Liquid X Printed Metals® Introduces Particle-free Products

Formulated at the Atomic Level, Two Disruptive Metallic Ink Products are Thin, Robust, Adaptable and Cost-effective

PITTSBURGH - Liquid X Printed Metals ®, Inc., (Liquid X®), an advanced

material manufacturer of functional metallic inks, today introduced two

particle-free inks. The inks will enable manufacturers in the

electronics and other industries to produce thinner, more cost-effective

and adaptable electronic components that will drive innovation in

consumer electronics, and advanced and medical technology among other

industries.

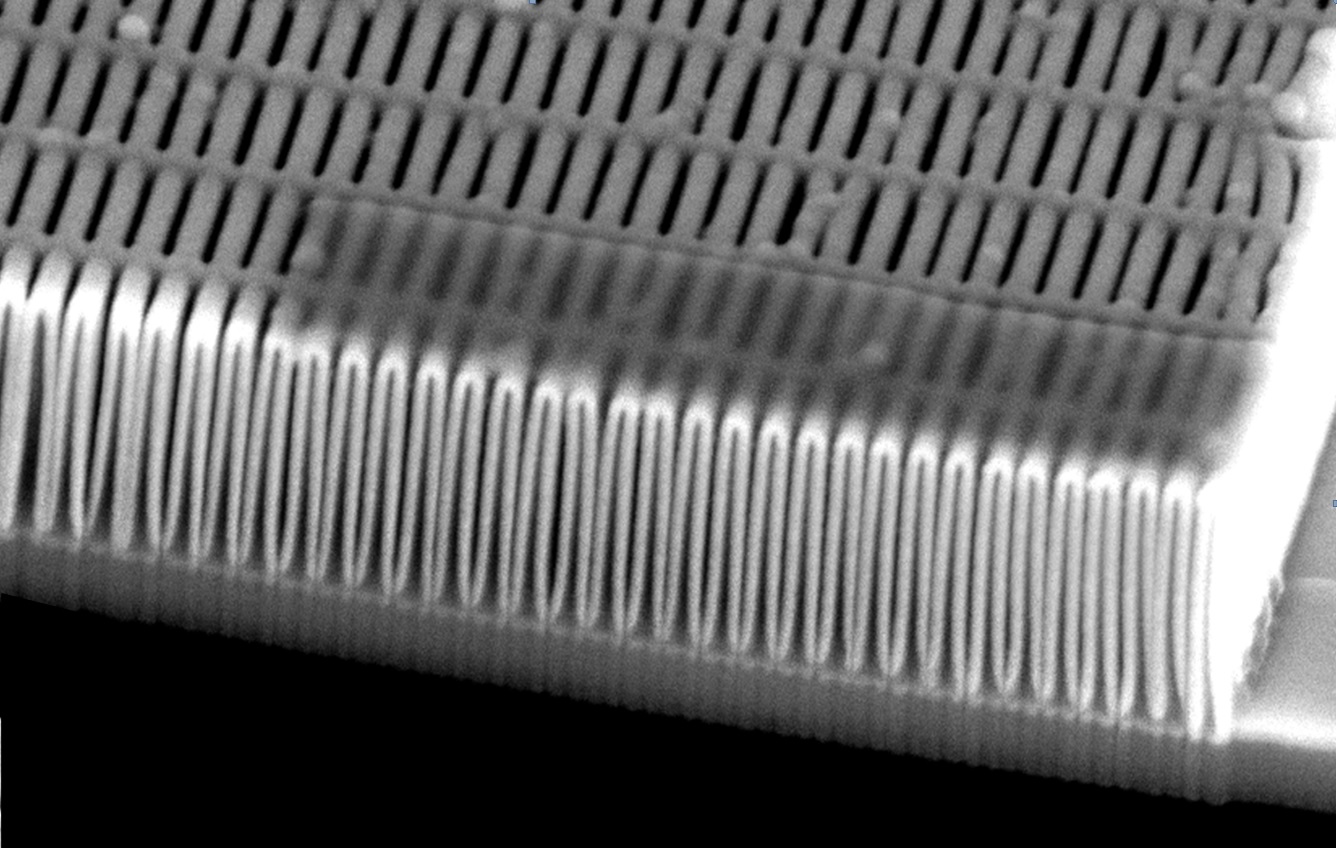

The company's two inaugural products, Liquid X®'s Silver Inkjet Ink and

Silver Flexo Ink were developed using an original and proprietary

particle-free formulation that leads to more cost-effective and

trouble-free processing; more durable traces that withstand bending and

flexing; adherence to the full range of substrates; good conductivity;

excellent printability; and enhanced sustainability due to its

water-based composition.

"Liquid X® is introducing particle-free inks that eliminate problems

associated with other metallic inks that are made with less stable

nanoparticles or metal flakes, which are thicker and can cause clogging,

slowness and other problems in printing," said Greg Babe, President and

CEO of Liquid X®. "Our Silver Inkjet Ink and Silver Flexo Ink leverage

atomic-level technology, which represents the kind of powerful, robust

and adaptable innovation required to tap the fullest potential of

printed electronics."

Liquid X(®)'s molecular inks consist of novel metal complexes that are

printed as solutions that are used in the creation of films or traces

that exhibit high conductivity, are thin and precise, and allow for

low-temperature processing that enables adherence on a wide range of

substrates. And the low viscosity of the inks allow for use in printing

methods that include inkjet, aerosol jet, flexography, and gravure.

Liquid X(®)'s conductive inks are designed for applications that range

from transparent conductors and touchscreens, to photovoltaic,

industrial and automotive applications, and smart packaging.

Performance

Silver Inkjet Ink features viscosity at 6-9 cPs; Polar Protic Solvents;

thermal, photonic and infrared curing methods; adherence to all

substrates; and excellent stability when refrigerated. Film trace sheet

resistance for one layer is 0.5 - 1 ohms per square. Thickness for one

layer is 200-300 nm. Trace width is < 50 micrometers. (Adhesion,

tensile - ASTM D3359, 5B rating). (Adhesion shear - scrub resistant.)

[Gloss - ASTM D523 ISO 2813, At 60 degrees >70 Gloss Units (high

gloss)

Silver Flexo Ink features Flexo-Gravure deposition; viscosity at 110-140

cPs (1-50 RPM); 80-110 (60-100 RPM); ~25 sec #2 Zahn Cup; Polar Protic

Solvents; thermal, photonic and infrared curing methods; adherence to

all substrates; and excellent stability at room temperature or when

refrigerated. Film trace sheet resistance for one layer is 0.5 - 1 ohms

per square. Thickness is 1-3 microns. (dependent on anilox).

(Adhesion, tensile - ASTM D3359, 5B rating). (Adhesion shear - scrub

resistant.) [Gloss - ASTM D523 ISO 2813, At 60 degrees >70 Gloss

Units (high gloss)

In development is a product called Silver Stretchable Ink, which is

designed for stretchable substrates such as fabrics or elastomers.

Applications for Silver Stretchable Ink include wearables, soft robotics

and other customized applications.

About Liquid X

Liquid X Printed Metals®, Inc. is a technology company headquartered

Pittsburgh, Pennsylvania that manufactures functional metallic inks. The

company's inks are considered disruptive in that their technology is on

the atomic level. This provides processing advantages and achieves

better metal film properties than other metallic inks that feature

nanoparticles and metal flakes which create instabilities. Visit:

www.liquid-x.com.

%20(1).png)