[Reposted from UCT Blog, LINK] In a manufacturing environment, productivity is dependent on predictability, and keeping operating equipment to a scheduled maintenance interval is the key to meeting performance targets.

For many chambers, in-situ cleaning is not an option to manage by-product buildup, and the scheduled preventative maintenance (PM) cycle involves replacing parts to maintain specifications. Ideally, the parts removed from a chamber are cleaned and returned to the fab for reuse, minimizing the cost of ownership (CoO) for the tool.

Crystalline Al2O3 by-product and trace metals deposited on quartz parts in etch chambers raise an issue as they can peel and cause particle problems leading to un-scheduled chamber downtime. It is very important to remove these by-products and trace metals from the quartz parts on a regular basis during PM. However, stripping crystalline Al2O3 (and trace metals) from quartz without compromising the quartz substrate can be a challenge.

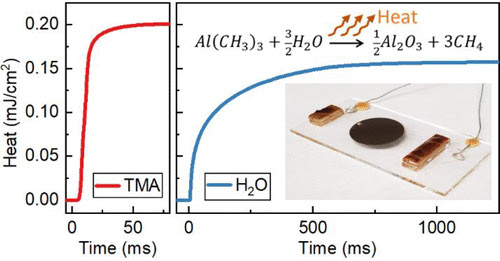

In order to address this problem, UCT and a chipmaking customer worked with coating partner Inficon to come up with a novel solution. This solution involved coating the quartz parts with a sacrificial atomic layer deposition (ALD) film and developing a cleaning and texturing refurbishment process.

ALD is used broadly within semiconductor devices, but ALD films are not used on the parts within production chambers. A high quality, conformal ALD film and a cleaning process with high selectivity to the quartz base material would be ideal to enable by-product removal. Texturing the surface would increase the mechanical adhesion of the by-product layer, reducing the risk of delamination. The highly conformal nature of the ALD film maintains the target surface texture and helps manage surface trace metals.

These quartz parts with a specified surface roughness were coated with at least 200nm of amorphous ALD Al2O3 films. After running in a chamber under process conditions, the by-product coated parts underwent a proprietary chemical strip process developed to remove the ALD Al2O3 film and by-product deposition. The quartz substrate showed no degradation as characterized using x-ray fluorescence (XRF), particle level, and roughness measurements.

This process is now qualified with the customer and the recycled quartz parts provide >75% reduction in Cost of Ownership (CoO). The ALD material was >99.999% pure, fully amorphous, and had a low intrinsic surface roughness. The delamination failure, which typically impacts 16% of all installed parts, was eliminated and a higher percentage overall of the quartz parts met mean time between clean (MTBC) target or full PM. The results were presented at the 2022 ALD/ALE conference with the above poster.

%20(1).png)