Thursday, September 15, 2022

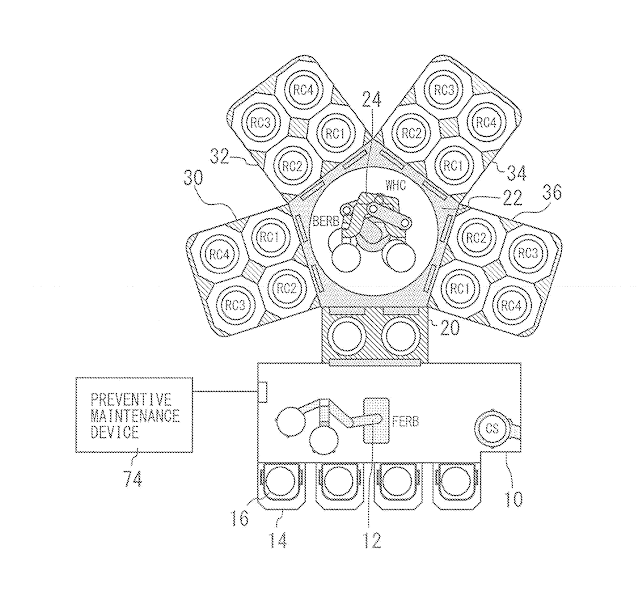

AlixLabs AB today announced that the company has been granted a second patent in the USA relating to Atomic Layer Etch Pitch Splitting (APS) for semiconductor manufacturing

TSMC to double energy efficiency and clean water consumption for semiconductor wafer manufacturing

- double energy efficiency after five years of mass production for each process technology

- reduce unit water consumption (liter/12-inch equivalent wafer mask layers) by 30% (Base year: 2010)

Friday, September 9, 2022

Semiconductor Equipment Consumables - Silicon Parts, in High Demand with Continued Shift Toward Asia

For more information details on the Silicon Parts market and growth trajectory, go to: https://lnkd.in/gM9GMNUs

SEMICON Europa 15 to 18 November, Munich Germany - Chips Powering the Data Age

Europe Chemical Supply Chain – Impact of Fab Expansions

Monday, September 5, 2022

Chipmetrics announces completion of the seed investment round

Sunday, September 4, 2022

3D Printing by ALD with Atlant 3D's Maksym Plakhotnyuk - ALD Stories

Tokyo Electron is forcastiong high continued sales in semiconductor equipment sales 2023 - slow down in DRAM

Samsung Electronics Breaks Ground on New Semiconductor R&D Complex in Giheung, Korea

Samsung to invest KRW 20 trillion by 2028 to build advanced research facility

- Samsung Electronics plans to invest about KRW 20 trillion by 2028 for the complex in an area covering about 109,000 square meters within its Giheung campus.

- The new facility will lead advanced research on next-generation devices and processes for memory and system semiconductors, as well as development of innovative new technologies based on a long-term roadmap.

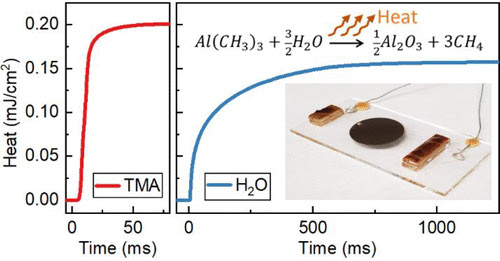

Resolving the Heat of Trimethylaluminum and Water Atomic Layer Deposition Half-Reactions

J. Am. Chem. Soc. 2022, 144, 33, 15203–15210

Publication Date:August 9, 2022

https://doi.org/10.1021/jacs.2c05460

Saturday, September 3, 2022

ASM reports that the ALD market is expected to grow by a CAGR of 16%-20% from 2020 to 2025

ASM International presented its Q2/2022 report in July and a new record orders of EUR 943 million driven by robust new node spending in logic/foundry and by recent wins in memory, particularly for ALD gap-fill in 3D-NAND and continued adoption of HKMG in DRAM.

- TechInsights expects WFE to increase by 21% in 2022 (July 2022)

- Strongest growth in leading-edge nodes, spending on 7nm and below expected to grow from ~25% of WFE in 2020 to ~42% of WFE in 2025

- Gartner expects total WFE to increase by 19% in 2022 (July 2022)

Friday, September 2, 2022

Oxford Instruments validates Plasma Etch process as alternative to SiC CMP

Thursday, September 1, 2022

UPDATE - ASD 2023 will be held in Incheon National University South Korea April 2-5, 2023

PROGRAM COMMITTEE:

- Rudy J Wojtecki (IBM)

- Stacey F Bent (Stanford University)

- Annelies Delabie (imec)

- John G Ekerdt (University of Texase)

- Dennis Hausmann (Lam Research)

- Erwin Kessels (Eindhoven University of Technology)

- Adrie Mackus (Eindhoven University of Technology)

- Ravi Kanjolia (EMD Electronics)

- Gregory Parsons (North Carolina State University)

- Robert Clark (TEL)

- Sean Barry (Carleton University)

- Han-Bo-Ram Lee (Incheon National University)

- Marko Tuominen (ASM)

- Sudipto Naskar (Intel)

- Anuja DaSilva (Lam Research)

- Kristen Colwell (Intel)

#ASD2023 will be held in Incheon National University @inupr from April 2nd to 5th, 2023. An official website will be online soon! Stay tuned! #ALDep #ASDep pic.twitter.com/fWt6KmoYML

— ASD2023 (@asd2023korea) September 1, 2022

WEBINAR - Production-suitable 200 mm batch ALD/MLD thin film encapsulation toward flexible OLED manufacturing

Supply Tightening Expected for Specialty Electronic Gases

Demand to outpace supply for NF3 and WF6 unless alternatives come into play

Wednesday, August 31, 2022

Webinar Atonarp’s Aston in-situ metrology solution for Spatial ALD

|

|

|

Equipment Suppliers Brace For GaN Market Explosion - including Atomic Layer Etch (ALE)

- Superior uniformity and repeatability enabled by a symmetrical chamber design, industry-leading electrostatic chuck technology, and independent process tuning features

- High productivity with low defectivity on multi-film stacks enabled by in-situ etch capability, continuous plasma, and advanced waferless auto-clean technology

- Improved critical dimension uniformity using proprietary Hydra® technology that corrects for incoming patterning variability

- Corvus® plasma sheath tuning for maximum yield of wafer-edge dies

- Atomic-scale variability control with production-worthy throughput enabled by plasma-enhanced ALE capability

- Upgradable products for low cost of ownership over several device generations

Tuesday, August 30, 2022

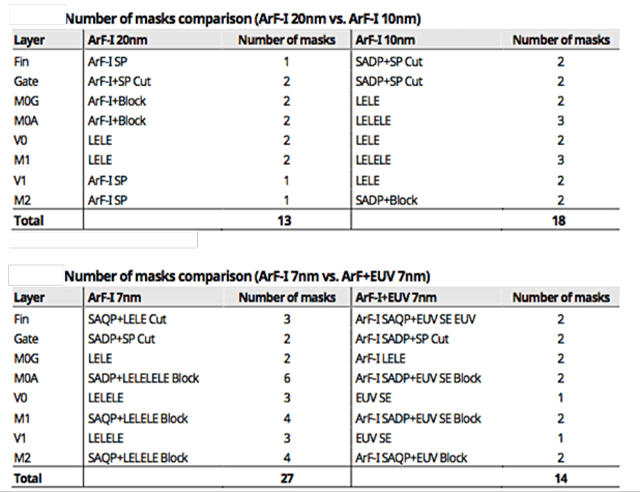

Comparison confirms that SMIC reaches 7nm without access to western equipment & technologies

Similarities with TSMC 7nm have been found

Monday, August 29, 2022

Materion to develop advanced chemicals for EV batteries, semiconductor chips at new facility

Sunday, August 14, 2022

ALD IGZO application for Monolithic 3D Integration

LucidaTM S Series for semiconductor is a high throughput ALD system with thermal or plasma process for 300 mm wafers and is able to deposit various oxides (HfO2, ZrO2) and metals (TiN, TaN, Ru) with excellent property and film uniformity.

Source: www.ncdtech.co.kr

Wednesday, August 3, 2022

Swagelok supports semiconductor manufacturers with new ALD valve

Sunday, July 17, 2022

Chipmetrics High Aspect Ratio Test Chip launched at ALD2022 in Ghent

At the recent AVS ALD2022 Conference in Ghent, Belgium, I made several rounds in the ALD industrial exhibition and met up with Chipmetrics Oy from Finland. Chipmetrics produce test structures, chips, and wafer concepts for advanced materials and microelectronics manufacturing, many specifically for ALD. Their main product – PillarHall test chip – is developed for advanced thin film process conformality characterization to accelerate applications of conformal 3D thin films. The Pillar Hall test chip has a lateral, very high aspect ratio structure to determine conformality when developing new ALD hardware, processes, and precursors.

Chipmetrics at AVS ALD2022 in Ghent, Belgium (Lower photo: Zahra Ghaderi, Mikko Utriainen and James Song)

What caught my eye this time was their new vertical high aspect ratio test chip - VHAR1 silicon test chip which consists of an array of vertical high aspect ratio holes. The holes have a constant hole diameter of 1 μm, and a depth of 200 μm over the whole chip area 15 × 15 mm. The deposited film penetration depth profile can be measured by cross-sectioning as normally done with the vertical high aspect ratio test structures.

This structure resembles the situation in semiconductor devices such as DRAM, 3DNAND, and TSVs. It can undoubtedly get valuable information and understanding when developing ALD processes for large surface areas with high aspect ratios. Anyone that has developed new ALD processes knows that not only the aspect ratio plays a role but also the total surface area since you need to achieve a sufficient dose of the precursors at the right process conditions to achieve perfect conformality very fast to be productive and minimize precursor decomposition, "CVD effects" and have effective purging of precursors and ALD process byproducts.

For more information, please find contact information here to Chipmetrics: LINK

Links

PillarHall – introduction in SlideShare

PillarHall – introduction in YouTube

PillarHall – short introduction in YouTube

Video: How to use PillarHall test chip

PillarHall Web Site

About Chipmetrics:

Chipmetrics is a forerunner in productizing test structures, test chips, and wafer concepts for advanced materials and microelectronics manufacturing.We are experts in thin film conformality characterization. Our main product – PillarHall test chip – is developed for advanced thin film process conformality characterization to accelerate applications of conformal 3D thin films.

Chipmetrics Oy is a part of the emerging Atomic Layer Deposition (ALD) industry and research community. Our headquarters are in Finland – in the country of the origin of ALD.

%20(1).png)