Alkane - Hafnium product breakthrough consolidates Dubbo Project business case.

Summary

- Alkane’s wholly owned subsidiary, Australian Strategic Materials Ltd (ASM), has developed high‐purity hafnium dioxide products tailored to meet market requirements.

- Hafnium oxide exceeding 99.8% HfO2, and 99.9% (Hf+Zr)O2, has been produced using a proprietary process to separate hafnium from zirconium at the demonstration pilot plant at ANSTO.

- Over the past 12 months, ASM has consulted extensively with industry to confirm growing market demand for high‐purity hafnium, which currently depends on supply from the production of zirconium metal for specialty alloys and the nuclear industry.

- Global shortage of hafnium anticipated as demand is poised to outstrip current supply.

- Hafnium metal for super alloys is currently trading in a US$800 ‐ $900/kg range. The ASM business case assumes a conservative product price of US$500/kg for its oxide.

- ASM will initially produce 25tpa hafnium to meet projected market demand, ramping up to higher quantities as required.

Download :

Download (PDF, 718KB)

Development of high‐purity hafnium dioxide

Australian Strategic Materials Ltd (ASM), a wholly owned subsidiary of Alkane Resources, has successfully developed a high‐purity hafnium dioxide (HfO2) product that will be directly marketable as a feed material for a number of downstream applications and for producing metallic hafnium. The technical specifications of this material have been tailored to meet global market requirements, following extensive industry consultation over the past 12 months.

Metallic hafnium is the fastest growing market for hafnium and the most significant by volume, particularly due to the use of hafnium in superalloys and other aerospace alloys. The usual precursor is hafnium dioxide, which needs to be recovered from zirconium metal production streams. The high purity hafnium dioxide developed by ASM exceeds 99.8% HfO2, and 99.9% (Hf+Zr)O2, providing the ideal feedstock for the high‐purity metallic hafnium that is in demand for alloying purposes. A high purity hafnium chemical precursor has also been developed.

The new products were produced by a proprietary process at ASM’s Demonstration Pilot Plant at the Australian Nuclear Science and Technology Organisation (ANSTO) in Sydney, New South Wales. The process flowsheet for the Dubbo Project consists of a sulphuric acid leach followed by solvent extraction recovery and refining to produce several products, including zirconium, hafnium, niobium and rare earths. The process pathway to recover hafnium was developed in 2015 and proved during 2017, and allows the flexible recovery of high‐purity hafnium dioxide from the high‐purity zirconium stream.

The development of this high‐purity hafnium dioxide material demonstrates the ability of ASM to produce a highly marketable hafnium product out of the Dubbo Project. ASM will continue to work with industry to secure offtake agreements and develop further enhanced products, with the view to establishing a customer base for hafnium products ahead of plant commissioning.

Hafnium market and outlook for future growth

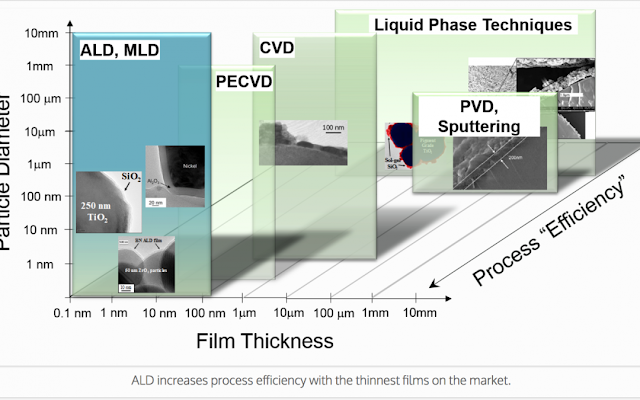

Global demand for hafnium is rising particularly for use in metallic form, which currently accounts for around 85 per cent by volume (60% superalloys, 15% plasma cutting tips, 10% nuclear control rods). Emerging aerospace applications are expected to consume further significant volumes of metallic hafnium. Hafnium dioxide is meanwhile emerging as a material of choice in semiconductors and data storage devices (ferro‐electric applications), while many future industries such as those based on its thermo‐electric properties and super high temperature ceramics for supersonic aircraft and space vehicles will also rely on materials containing hafnium.

Projected growth in demand is poised to exceed current production, which is limited to about 70tpa (83tpa HfO2), since hafnium is typically only extracted from zirconium processing streams for nuclear energy applications requiring high‐purity zirconium. Market research by ASM and independent international market consultants forecasts a 2026 base demand of 112tpa (132tpa HfO2), and an unconstrained high‐demand case of 151tpa (178tpa HfO2).

The Project represents a unique source of hafnium that is independent of all traditional markets – including China (currently accounting for at least 75% of world production of zirconium materials, and over 95% of zirconium chemicals), the nuclear zirconium industry and the zircon industry in general. To ensure a sustainable business case, the ASM processing plant will undergo staged ramp‐up in production volumes to keep pace with world demand. Start‐up volumes will be around 25tpa hafnium metal (30tpa HfO2), increasing in line with market growth; full plant capacity is conservatively estimated at 200tpa.

Hafnium product pricing remains opaque due to security issues and limited production but the metal for super alloys is currently trading in a US$800 ‐ $900/kg range. The ASM business case assumes a conservative product price of US$500/kg for its oxide.

%20(1).png)