Behold ALD people - After defeating both PVD and CVD numerous times there will be now rest for the PLD guys ar coming - Solmates’ PLD platform is the next disruptive deposition technology

following the adoption of atomic layer deposition (ALD) for thin film

manufacturing - Welcome to the club PLD people!

ENSCHEDE, the Netherlands, April 18th 2016-

Solmates has received an important and high profile order for its

Pulsed Laser Deposition (PLD) equipment from world–leading

nanoelectronics research center imec. The system is scheduled for

delivery to imec in Leuven, Belgium during Q2 2016.

Solmates’ advanced PLD equipment is

fundamental in helping to accelerate the entry of new processes into

commercial products. It plays a key role in the development of future

chip designs and the integration of new materials for next generation

transistors.

Solmates will become a member of imec’s

Industrial Affiliation Program (IIAP) Beyond CMOS. This program focuses

on the integration and benchmarking of novel device concepts beyond

traditional transistor scaling. These include piezoelectrics for

alternative computing devices and 2D materials such as graphene and MoS2

for ultimate scaling.

“This important and significant deal fits

our roadmap towards mainstream CMOS compatibility,” commented Solmates’

CEO Arjen Janssens, “Imec is a world-leading center for nanoelectronics

with significant global partnerships and therefore represents the

perfect gateway to this key market.”

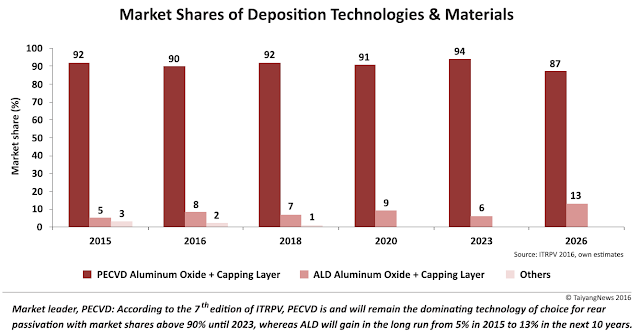

Solmates’ PLD platform is the next

disruptive deposition technology following the adoption of atomic layer

deposition (ALD) for thin film manufacturing. The technology uses a

laser to create a plasma of the material to be deposited, enabling

industrial quality deposition of new generation materials. An automated

tool offers high yield, customized deposition of various ‘More than

Moore’ materials on a wide variety of different substrates. The

technology is already in use at various customer sites and several

processes are qualified for (Piezo) MEMS, LED and PowerIC applications.

Solmates owns key patents related to PLD technology and processes.

%20(1).png)