Friday, March 3, 2023

Applied Materials’ Pattern-Shaping Technology - Centura Sculpta

Saturday, February 18, 2023

ALD Stories Ep.20 - The story behind AlixLabs and ALE Pitch Splitting

Jonas Sundqvist joined the ALD Stories podcast again to talk about his company, AlixLabs! Check out their Atomic Layer Etch Pitch Splitting tech and how it challenges traditional patterning techniques.

Spotify - https://lnkd.in/djrMbZ-v

Apple - https://lnkd.in/d93sW3JK

Friday, February 10, 2023

Picosun contributes funds to Aalto University to strengthen semiconductor know-how

Friday, February 3, 2023

A True Pioneer of ALD Research with Jeffrey Elam – ALD Stories

Thursday, February 2, 2023

Dutch ALD euipment leader ASM to invest $100 mil. in Korea for facility expansion

Wednesday, February 1, 2023

Go Go Hellzilla - the ALD Monster in Helsinki

Asking the AI powered ChatGPT some simple questions

I have been asking the AI powered ChatGPT some simple questions - what do you think? Is there a better way to explain ALD and ALE in a simple way? I like the ALE answer more than the ALD answer.

So I reiterated and asked ChatGPT to give a very simple answer for ALD, which I like a bit more. I would probably swap electronics for semiconductor, which I did using the teaching function :-)

Tuesday, January 17, 2023

Thermal Atomic Layer Deposition of Gold

Reductive Thermal Atomic Layer Deposition Process for Gold

Anton Vihervaara, Timo Hatanpää, Heta-Elisa Nieminen, Kenichiro Mizohata, Mykhailo Chundak, Mikko Ritala*Monday, January 9, 2023

Xiaomi Redmi Note 12 Pro Plus 5G use ALD coating to avoid flare and ghosting under bright light

Friday, December 23, 2022

Picosun initiates R&D program in Finland for sustainable semiconductor manufacturing

Photo, Björn Engström, Oravais, Ostrobothnia, Finland.

Thursday, December 22, 2022

SparkNano's Spatial ALD tool decreases the of Iridium while increasing the production capacity of electrolyzers for green hydrogen

Technical features (12 inch system)

Substrate types flat substrates like polymer and metal foils, wafers, glass and porous substrates

Substrate size

A free envelope of 320 mm x 360 mm x 5 mm is available. In this volume any flat substrate can be placed with a substrate specific holder

Process

Both thermal and plasma enhanced s-ALD

Swedish Nanexa signs Evaluation Agreement with and issues a directed shares to Novo Nordisk for ALD based PharmaShell(R)

Monday, December 19, 2022

Foundations of atomic-level plasma processing in nanoelectronics (Open Access)

Foundations of atomic-level plasma processing in nanoelectronics

Thin layers paved the way for ASMI’s success - Outgoing CTO Ivo Raaijmakers explains what atomic layer deposition has brought the semiconductor industry

This vision has come true. The technique that ASMI acquired through Microchemistry – atomic layer deposition (ALD) – has become an integral part of the semiconductor manufacturing process. And that’s just the beginning, according to Raaijmakers. The demands placed on material layers are ever higher – thinner, more uniform, featuring just the right properties – and ALD is the best technique to meet them, the former CTO argues.

Well before ALD had proven itself in the deposition of high-k materials, Raaijmakers was already looking at which applications would follow. On his initiative, ASMI acquired Korean company Genitech in 2004, a specialist in plasma-enhanced ALD technology (PEALD). Plasmas are more reactive than un-ionized gases and therefore can deposit materials at lower temperatures. Because chipmakers often have to deal with strict temperature budgets, PEALD expands the scope of ALD.

Saturday, December 17, 2022

ALD Stories Podcasts by Tyler Myers

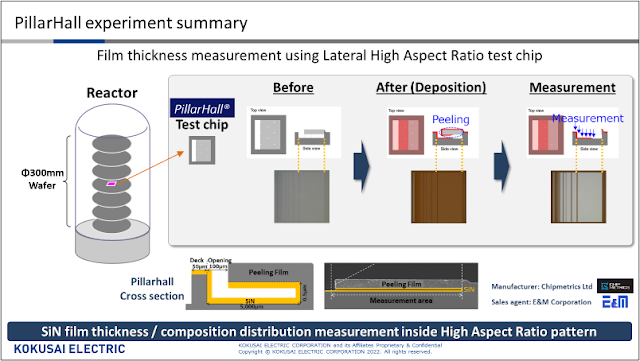

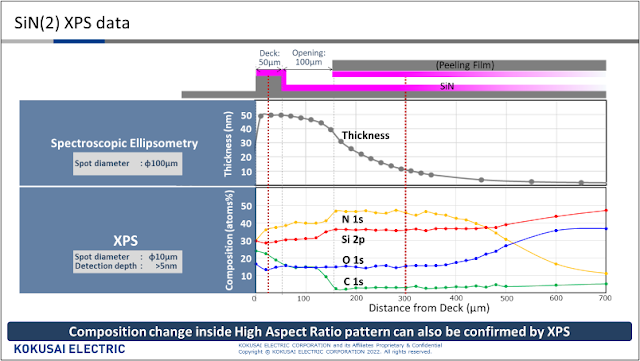

Kokusai Electric relies on patterned 3D substrates in thin film process metrology from Chipmetrics

Friday, December 16, 2022

MIT.nano adds new instruments to create and analyze at the nanoscale from Arradiance

Friday, November 25, 2022

Applied Materials Delivers Strong FY 2022 Numbers including Picosun ALD

LINK: https://ir.appliedmaterials.com/

The company’s uniquely enabling technology and growing installed base will be its key growth drivers as chipmakers accelerate ramping up of new process nodes in R&D for high-volume manufacturing.

Key developments in FY 2022

- Applied Materials acquired Picosun, a Finland-based innovator in atomic layer deposition (ALD) technology. This acquisition broadens Applied’s product portfolio and puts it in a great position to capture a large portion of the specialty semiconductor market in the coming years.

- Collaboration with the Institute of Microelectronics (IME), a research institute under Singapore’s Agency for Science, Technology and Research (A*STAR). IME’s strategic R&D capabilities complement well Applied’s expertise in advanced packaging solutions and will accelerate material, equipment and process technology solutions for hybrid bonding and other emerging, 3D chip integration technologies.

- Introduced new Ioniq™ PVD system to solve wiring resistance challenges of 2D scaling. This new integrated solution offers a significant reduction in electrical resistance, which has become a critical bottleneck to further improvements in chip performance and power.

- Semiconductor Systems revenue increased 15% YoY in FY 2022 to $18,797 million on account of strong orders as customers continued to invest in next-generation technology.

- Applied Materials’ service revenue increased 11% YoY in FY 2022 to $5,543 million, accounting for 21% of the annual net revenue.

- Display and Adjacent Markets revenue decreased 19% YoY in FY 2022 to $ 1,331 million.

- Non-GAAP gross margin was at 46.6% in FY 2022.

- Non-GAAP operating profit grew by over 7% to $7.86 billion.

- Non-GAAP EPS increased nearly 13% to $7.70.

- Total ending backlog increased 62% to $19 billion with Semiconductor Systems backlog increasing 90% to nearly $12.7 billion and services backlog increasing 30% to over $5.6 billion.

- The company generated about $5.4 billion in operating cash flow and over $4.6 billion in free cash flow.

- The company’s installed base grew 8% YoY in FY 2022.

- The number of tools under comprehensive, long-term service contracts grew 16% YoY with the over 90% renewal rate for these agreements demonstrating the value customers see in subscription services.

- New export regulations for US semiconductor technology sold in China reduced Semiconductor Systems and AGS fourth quarter revenue by approximately $280 million.

Tuesday, November 8, 2022

Recent ALD news on shared on Twitter #ALDep

Area Selective ALD of Ruthenium #ALDep #ASDep https://t.co/LInkrCfXNf

— Jonas Sundqvist 🐳 (@jv3sund) November 7, 2022

TOPCon solar cell achieves 24.2% efficiency via new plasma-assisted atomic layer deposition tech from Nantong University, China#ALDep #solar #solarcell #china #photovoltaic https://t.co/VjMBvz8Ib0

— Jonas Sundqvist 🐳 (@jv3sund) November 7, 2022

Researchers at the @HelsinkiALD are developing thin films needed in new types of halide perovskite solar cells, and matching #ALDep processeshttps://t.co/JzBSalKiuN pic.twitter.com/tWv4WMAgvA

— Jonas Sundqvist 🐳 (@jv3sund) November 4, 2022

University of Erlangen demonstrate sALD of Crystalline Metal–Organic Framework Thin Films (MOFs)#ALDep #MOFs https://t.co/cUgGOWkJjl pic.twitter.com/B1l0S4qQM7

— Jonas Sundqvist 🐳 (@jv3sund) November 4, 2022

Abstract submission is now open for the AVS 23rd International Conference on Atomic Layer Deposition (#ALD2023) and the 10th International Atomic Layer Etching Workshop (#ALE2023). Deadline: Feb. 15, 2023. https://t.co/QvY8bu8KPp #ALDep #ALEtch @AVSALD https://t.co/x2MrKttxk9 pic.twitter.com/BgYxx19FHK

— AVS (@AVS_Members) November 2, 2022

SparkNano Raises EUR 5.5M to Scale Spatial Atomic Layer Deposition for Energy Applications in a round led by ALIAD Venture Capital by Air Liquide

SparkNano Raises EUR 5.5M to Scale Spatial Atomic Layer Deposition for Energy Applications in a round led by ALIAD Venture Capital by Air Liquide.

SparkNano - LINK (linkmagazine.nl)

Friday, November 4, 2022

ALD coatings for next-generation solar cells

Members of the research group next to the ALD reactor. Georgi Popov (left), Marianna Kemell, Alexander Weiss and Mariia Terletskaia. (Image: Riitta-Leena Inki)

“As these new types of solar cells can be transparent, they can be installed in, for example, windows. They are also flexible, which increases their uses,” says Senior University Lecturer Marianna Kemell, who heads the research project funded by the Academy of Finland.

“We identified suitable chemicals and were able to design a reaction that enabled us to create a metal iodide coating through deposition for the first time. We were able to demonstrate that this can actually be done through atomic layer deposition. The first successful trial was carried out with lead iodide, which was then processed into CCH₃NH₃PbI₃ perovskite through a further reaction,” Popov says. “The research article was published in the refereed Chemistry of Materials scholarly journal. Later on, we also developed ALD processes for caesium iodide and CsPbI₃ perovskite.”

“If at some point we start making tandem solar cells, which combine a silicon cell and a perovskite cell, we know how to make that perovskite. We are developing the recipes and the chemistry used to grow perovskite,” Popov says.

“The current plants manufacturing solar cells in China and elsewhere are able to adjust their equipment to produce ALD-coated solar cells,” says Popov.

“We are developing the future technical solutions that will gradually replace and supplement current production. In the future, fewer resources will be needed for production, and, thanks to increasingly effective cells, less surface area as well. When solar cells can be installed on uneven surfaces in addition to even ones, we no longer need to build solar parks in fields, as fields are needed for other purposes,” Popov notes.

“The best part of silicon-based cells is that they last roughly 20 to 30 years and will continue to function even after that, albeit possibly less efficiently. Since solar cells produced with the PERC technique are the current state of the art, and they are available, it is advisable to acquire as many of them as possible. They will pay for themselves,” Senior University Lecturer Kemell says.

Samsung use NCD ALD for wirebonding alternatives to expensive Gold

University of Erlangen demonstrate sALD of Crystalline Metal–Organic Framework Thin Films (MOFs)

Solution Atomic Layer Deposition of Smooth, Continuous, Crystalline Metal–Organic Framework Thin Films

Chem. Mater. 2022, XXXX, XXX, XXX-XXX

Publication Date:November 2, 2022

https://doi.org/10.1021/acs.chemmater.2c01102

Monday, October 10, 2022

Samco launches new ICP Tornado Plasma ALD system

“We are also considering a cluster ALD system that can connect multiple reaction chambers for production” says Tsukasa Kawabe, President and COO of Samco. “The launch of the AD-800LP will greatly enhance our presence in the world ALD equipment market.” Tsukasa adds.

NCD’s ALD technology and equipment for oxidation barrier of copper-based substrates

Copper is a metal used widely as the main material of Printed Circuit Board (PCB) and Lead Frame. But it is required to protect the oxidation because copper is easily oxidized in the condition of humidity, temperature, and pH, etc.

Electroless Nickel Immersion Gold (ENIG), Organic

Solderability Preservative (OSP), Immersion Sn or Ag (ImSn or ImAg) is

generally used to prevent oxidation of opened copper area after Solder Masking

in PCBs. The lead Frame is protected from oxidizing by plating Au, Ag, Pd, and Ni

after Lead Frame forming.

Recently, many groups have studied about preventing

oxidation on the surface of copper by various corrosion protection layers of

ALD metal oxides. Especially, Appling Al2O3 layer to the oxidation barrier is

actively being researched.

< Surface images and TEM & EDS of Cu plates coated by ALD thin films after annealing test >

After depositing Al2O3 layers on Cu-plated plates with various film thicknesses and process temperatures, the oxidation and corrosion behavior of the coated copper was examined with different annealing times in the oven. There was no oxidation before annealing, but after annealing for 1hr, as the sample’s thickness lowered and process temperature decreased, the oxidation happened and increased gradually. There was no oxidation on the plates coated with 50~60 ALD cycles and at process temperatures of 70~100℃ after annealing for 5hr, and oxidation didn’t occur only in the case of 60 cycles and 100℃ after annealing for 24hr.

To analyze the change of the structure and confirm the oxidation

behavior, TEM and EDS were measured on 5 and 10nm Al2O3 coated Cu plates at 100℃.

The results showed that a thick Cu oxide layer was built by combining Cu coming

out through the 5nm Al2O3 layer and outer oxygen after annealing.

On the other side, in the case of depositing 10nm Al2O3 film,

the ALD layer was maintained after annealing, so Cu oxide layer wasn’t built on the

surface. Therefore it confirmed that 10nm ALD Al2O3 layer showed an excellent

corrosion barrier.

< ALD equipment for Lead Frame and PCB >

Copper-based PCBs and Lead Frames for semiconductors may have great properties to prevent humidity and oxygen by ALD-coated corrosion barriers.

NCD has high volume and large area ALD equipment and

technology for this kind of application. ALD tools for Lead Frames could be

used by adding a dedicated transfer module on the base of Lucida GSH Series. And

NCD has been developing new ALD equipment, Lucida GP Series, for large and

flexible PCB substrates. NCD would extend the new ALD application area continuously

through constant R&D.

Source:

http://www.ncdtech.co.kr/2018/bbs/board.php?bo_table=eng_board_05&wr_id=57

%20(1).png)