Since the finding of ferroelectricity in HfO2 films of sub 10 nm thickness by Tim Böscke*, (

US8304823B2 NaMLab gGmbH) more then 10 years ago many leading R&D teams and semiconductor companies has confirmed the findings. Now also ferroelectricity in nanosized HfO2 crystalsby has been confirmed by the "Hafnia team” within the Nanostructures of Functional Oxides group, Zernike Institute for Advanced Materials, University of Groningen (UG), the Netherlands (

LINK).

* then at the DRAM Company Qimonda

Figure shows inside view of vacuum chamber in which the process of 'pulsed laser deposition' takes place, used to create the hafnium oxide crystals in this study. On the left the glowing substrate on which the film is growing with atomic control; in the center the blue plasma of ions that is created by shooting a laser on a target with the right chemical composition (target visible on the right side of the figure). | Photo Henk Bonder, University of GroningenFerroelectric materials have a spontaneous dipole moment which can point up or down. This means that they can be used to store information, just like magnetic bits on a hard disk. The advantage of ferroelectric bits is that they can be written at a low voltage and power. Magnetic bits require large currents to create a magnetic field for switching, and thus more power. However, according to the scientific community, the aligned dipoles in ferroelectric materials are only stable in fairly large groups; thus, shrinking the crystals results into the loss of dipole moment obstructing ferroelectricity based storage devices.

Nevertheless, eight years ago, the first publication by ex-Qimonda experts and researchers from Fraunhofer and RWTH Aachen (Appl. Phys. Lett.

99, 102903 (2011);

https://doi.org/10.1063/1.3634052) announced that hafnium oxide thin films were ferroelectric when thinner than ten nanometres and that thicker films actually lost their ferroelectric properties. This triggered many groups across the globe to dig deeper and confirm the claim of researchers from NamLab. Noheda and her group at University of Groningen was also one of them. Since the ferroelectric hafnium oxide samples used in the study carried out at NaMLab were polycrystalline and showed multiple phases, obscuring any clear fundamental understanding of such an unconventional phenomenon, Noheda and her group decided to study these crystals by growing clean (single-phase) films on a substrate.

Using X-ray scattering and high-resolution electron microscopy techniques, the group observed that very thin films (under ten nanometres) grow in an entirely unexpected and previously unknown polar structure, which is necessary for ferroelectricity. Combining these observations with meticulous transport measurements, they confirmed that the material was indeed ferroelectric. Surprisingly, they noticed that the crystal structure changed when the layers exceeded 10 nm, thus reaching the same conclusion as of the Namlab.

In the substrate that UG researchers used, the atoms were a little bit closer than those in hafnium oxide which strained hafnium oxide crystals a little. Moreover, at a very small size, particles have a very large surface energy, creating pressures of up to 5 GPa in the crystal. This altogether forces a different crystal arrangement and in turn polar phase in the HfO2 film.

One contradicting finding of the UG researchers is that the HfO2 crystals do not need a ‘wake-up’ cycle to become ferroelectric. The thin films investigated at NamLab turned ferroelectric only after going through a number of switching cycles (wake-up cycles) needed to align the dipoles in “uncleaned” samples grown via other techniques. In case of the pulsed laser deposition setup and the substrate used at UG, the alignment is already present in the crystals.

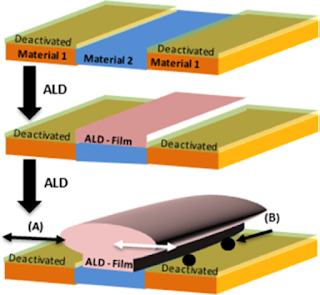

Meanwhile, NaMLab has explored ferroelectric properties in atomic layer deposition (ALD) based thin-films of doped HfO2, and has achieved revolutionary results (

LINK). A variety of dopant materials (Si, Al, Ge, Y, Gd, La and Sr) with a crystal radius ranging from 50 to 130 pm has been studied in addition to a mixed Hf1-xZrxO2. The aim is to develop a memory concept with the HfO2 based ferroelectric transistors (FeFET) as building blocks. The FeFET is a long-term contender for an ultra-fast, low-power and non-volatile memory technology. In these devices the information is stored as a polarization state of the gate dielectric and can be read non-destructively as a shift of the threshold voltage. The advantage of a FeFET memory compared to the Flash memory is its faster access times and much lower power consumption at high data rates. In the framework of a project together with GLOBALFOUNDRIES and Fraunhofer IPMS, which was funded by the Free State of Saxony, a one-transistor (1T) FeFET eNVM was successfully implemented at NaMLab in a 28 nm gate-first super low power (28SLP) CMOS technology platform using only two additional structural masks (

LINK). The electrical baseline properties remain the same for the FeFET integration, demonstrating the feasibility of FeFET as low-cost eNVM.

Guest Blog by: Abhishekkumar Thakur, Fraunhofer IKTS / TU Dresden

Location: Dresden, Germany

LinkedIn:

www.linkedin.com/in/abhishekkumar-thakur-16081991

%20(1).png)