Adisyn Ltd has taken a significant step toward advancing semiconductor technology with its recent investment in an Atomic Layer Deposition (ALD) machine from Beneq. On November 10, 2024, the company announced that its subsidiary, 2D Generation Ltd, ordered the specialized equipment to enhance graphene-coated interconnect technology, a breakthrough innovation in next-generation chip development. This strategic acquisition underscores Adisyn's commitment to driving innovation in critical markets such as defense, data centers, and cybersecurity. Through the collaboration between Adisyn and 2D Generation, alongside Beneq's cutting-edge ALD expertise, the partnership is set to address key challenges in semiconductor manufacturing, paving the way for faster, energy-efficient, and more reliable computing solutions.

Adisyn Ltd has invested in an Atomic Layer Deposition (ALD) machine from Beneq. On November 10, 2024, Adisyn announced that its subsidiary, 2D Generation Ltd, ordered a specialized ALD machine from Beneq to advance their semiconductor technologies, including graphene-coated interconnects. This acquisition aims to accelerate the development of next-generation chip technology, benefiting Adisyn's target markets such as defense applications, data centers, and cybersecurity.

2D Generation Ltd is an Israeli high-tech company specializing in graphene-based solutions for the semiconductor industry. Founded by entrepreneur and innovator Arye Kohavi, the company focuses on overcoming current technological limitations by developing faster, more energy-efficient computer processing solutions.

A significant advancement by 2D Generation is their patented method for depositing graphene coatings at temperatures below 300 degrees Celsius. This breakthrough enables the next generation of semiconductors to achieve further miniaturization, reduced power consumption, less heat generation, and greater computational power.

One of 2D Generation Ltd patent applications (US2024301554 AA) outlines a method employing ALD to apply graphene as a diffusion barrier or interfacial layer on non-metallic surfaces, such as dielectric or semiconductor layers. ALD is used to achieve precise, uniform deposition of graphene molecular precursor layers, enabling atomic-level control and ensuring high-quality graphene with minimal defects. The process operates at low temperatures (below 350°C), making it compatible with sensitive semiconductor manufacturing. The graphene is covalently bonded to the substrate using customized precursors containing tethering groups tailored for strong chemical interactions. These precursors, such as aromatic hydrocarbons with functional groups like trichlorosilyl or carboxylic acids, are designed to react with the substrate to form stable graphene layers. Precursor deposition methods include vacuum techniques like sublimation or evaporation, and the process may involve sequential cycles of different precursors to optimize uniformity, fill factor, and defect ratio. This approach addresses critical challenges in semiconductor interconnect scaling by providing a high-conductivity, robust diffusion barrier that prevents metal atom migration, enhances reliability, and supports higher current densities in advanced integrated circuits.

In July 2024, 2D Generation entered into a binding collaboration agreement with Adisyn Ltd, an Australian technology company, to develop high-performance, energy-efficient semiconductor solutions for AI and data centers. This partnership aims to leverage 2D Generation's semiconductor innovations alongside Adisyn's expertise in data center management and cybersecurity.

Furthering their collaboration, in November 2024, Adisyn Ltd announced a binding agreement to acquire 100% of 2D Generation Ltd's issued share capital. This acquisition is expected to enhance Adisyn's capabilities in developing advanced semiconductor technologies, particularly in defense applications, data centers, and cybersecurity.

Additionally, 2D Generation is a partner in the European Union's Connecting Chips Joint Undertaking, which includes research and innovation partners such as NVIDIA, IMEC, Valeo, Applied Materials, NXP, and Unity. This initiative focuses on accelerating the development of next-generation semiconductor chips to meet the growing demands of generative AI and other advanced technologies.

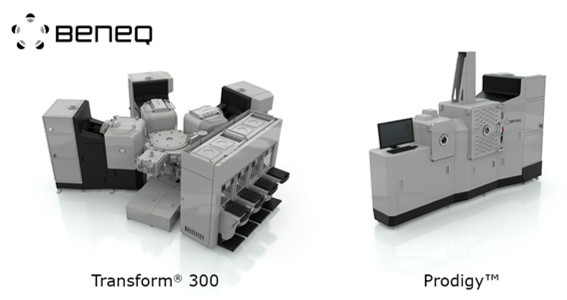

Beneq, founded in 1984 and headquartered in Espoo, Finland, is a global leader in Atomic Layer Deposition (ALD) technology, offering equipment and research services for semiconductor fabrication, batch production, research, and spatial ALD applications. Acquired in 2018 by Qingdao Sifang SRI Intellectual Technology Co. Ltd., Beneq focuses on industrial ALD thin film solutions and transparent displays. Its product portfolio includes automated ALD systems for high-capacity wafer production, batch production tools for diverse substrates, flexible research equipment, and roll-to-roll ALD systems. Beneq also provides coating, R&D, spare parts, and system upgrades, with offices in the US, China, and Japan. Qingdao Sifang SRI Intellectual Technology Co., Ltd., established in 2018 and headquartered in Qingdao, China, specializes in the development and manufacturing of advanced semiconductor process equipment. Supported by significant investments, including a Series B funding round in 2024 involving SAIC Motor Corporation, the company has achieved key milestones, such as developing China's first domestic high-energy ion implanter.

Sources:

Patbase

www.beneq.com

Presentation - Adisyn Ltd (ASX:AI1) - Listcorp.

New Generation Atomic Layer Deposition Machine Procured | INN

%20(1).png)