ESPOO, Finland, 23rd March 2020 – Picosun Group’s first priorities are customer satisfaction and health and wellbeing of the Group’s employees and customers. Picosun takes extremely seriously the global threat posed by the COVID-19 novel coronavirus epidemic and follows the rules set by governments and WHO. As the epidemic restricts global traveling, the importance of local offices and subsidiaries close to the customers is of utmost importance.

The last years have been the time of rapid growth and expansion for Picosun. Strong emphasis has been put on new recruitments especially on the service and support sector. Trained and qualified staff of service engineers are on call at the Group’s US locations in Texas, Arizona, and California and Asian locations in Japan, China, Taiwan, and Singapore. Dedicated sales and support personnel in Germany and France are available for the Group’s European customers. Local process support is also available on each continent.

At Picosun’s Finnish headquarters and local offices employees are encouraged to remote work from home whenever possible. Meetings are arranged virtually via video links and online platforms and inviting external visitors to the company’s premises is minimized to bare necessities. Cleaning of the premises and other hygiene measures have been intensified. All recruitment interviews are conducted remotely.

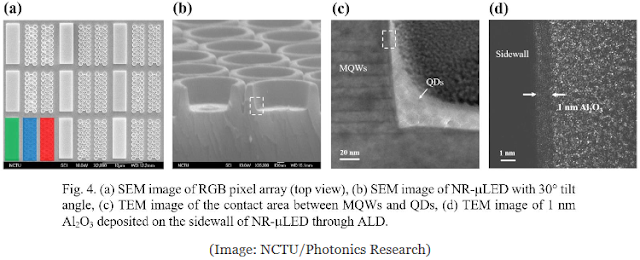

Despite of the challenging times, Picosun’s customer projects and deliveries continue. Process support and applications consultancy is always available from our Ph.D. level experts, and our Helpdesk serves 24/7 at support@picosun.com. Delivered PICOSUN® ALD system installations and commissioning, as well as customer support on-site, are taken care of by local Picosun offices with their trained and experienced staff.

“All of us here at Picosun wish good health and safety to everybody in this difficult and unexpected situation. In times like this, collaboration is the key to success and speedy recovery. Our business continues and we will put all our effort in sustaining the high level of quality that is the trademark of Picosun. We will further intensify our efforts to bring the benefits of ALD to medical industry. ALD is the very technology that enables our modern, mobile, data-driven and interconnected global society. Now is the time when this society can truly work together for better future,” says Jussi Rautee, CEO of the Picosun Group.

For more information regarding your projects or deliveries, please contact your respective Picosun sales or support contact person. For quotations for our ALD equipment and solutions, or process demo, please contact sales@picosun.com or coating@picosun.com, respectively.

As several expos and conferences the Group is sponsoring or exhibiting at have been postponed, please see the new dates in our event calendar on our website. Picosun is looking forward to meeting you all again later this year in good health and spirits!

%20(1).png)