Saturday, March 5, 2022

Electronic Gas Markets – Strong Growth, Pressing Supply-Chain Issues

Thursday, February 17, 2022

RASIRC Provide Record Low Resistivity Titanium Nitride Film Fabricated by Thermal ALD

Thursday, January 27, 2022

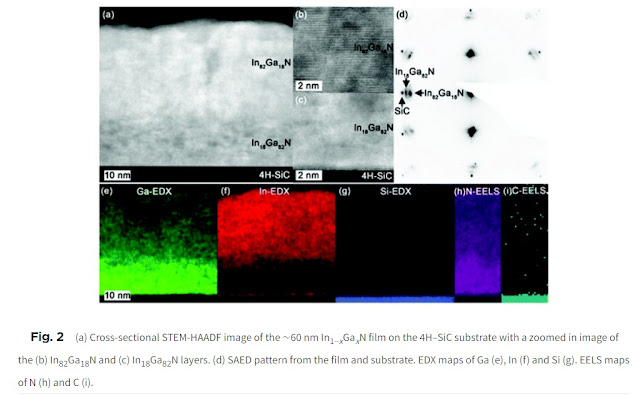

ALD InGaN with single precursor pulse of In & Ga

- The sequential pulsing of the precursors in ALD presents a challenge to depositing a homogeneous ternary material as only one precursor can be pulsed into the reactor at a time.

- Ternary materials are therefore deposited by ALD as stacks of two binary materials. In1−xGaxN could therefore be deposited as layers of InN and GaN in an ABAB⋯CBCB… super-cycle approach where A and C are In- and Ga-precursors, respectively, and B is the N-reactant. By varying the number of cycles for each binary material, the overall composition of the ternary material can be tuned.

- This approach relies on diffusion of the two binary materials to form a homogeneous ternary phase. Otherwise, a multilayer of InN/GaN is obtained. This ALD approach has been used to obtain In1−xGaxN with x ranging from 0.15–0.85 using trimethylindium and trimethylgallium.

- Here, an alternative method to depositing ternary materials by introducing both metal precursors with a single pulse. This renders mixing of the metals in both the growth direction and in the growth plane. This was achieved by mixing and co-subliming two solid metal precursors into the ALD chamber.

Wednesday, May 5, 2021

EMD Electronics Creates Center of Excellence for Atomic Engineering by Combining Thin Films R&D Lab with Intermolecular

- Unique capabilities with novel organo-metallic precursors and applications will enable customers to explore and test advanced materials for next-generation devices

- Centralized innovation hub to speed up the delivery of material solutions to customers

EMD Electronics "We've established a Center of Excellence for Atomic Engineering! Our Thin Films Applications R&D lab has merged with Intermolecular's advanced electronics capabilities to create a centralized innovation hub for our customers. This will enable seamless integration of testing and deposition of new materials for next-generation semiconductors." (Quote and photo above from EMD Electronics LinkedIn Announcement LINK)

Thursday, April 8, 2021

Pegasus Chemicals announce a new supply site in The EU in Sweden

UK ALD and CVD Precursor supplier Pegasus Chemicals announce a new supply site in Europe in Värmdö, Sweden Pegasus Chemicals AB thru a long-term collaboration with Fab Support AB - the biggest supplier of CVD and ALD precursor in North Europe. The location is very close to BALD Engineering HQ also in Värmdö! Welcome to Sweden and Värmdö in the Stockholm Archipelago!

ALD/CVD Metal Precursors US$640M Market Booming to US$910M in 2024

Wednesday, April 7, 2021

Ascensus acquires a global leader in high-purity specialty chemicals and CVD/ALD precursors Strem Chemicals, Inc.

Friday, March 5, 2021

EMD Performance Materials announces further investments of electronics business and new name: EMD Electronics

- New name reflects the product and service portfolio designed to enable the future of electronics in a data-driven world

- Investment into R&D and innovation centers in Tempe and Silicon Valley

- Patterning, deposition and spin-on dielectrics materials to make 3D NAND possible

- DSA – revolutionary way of building microchips of the future

- OLED for brighter, thinner, free-form displays

- Liquid crystals for electronic steerable antennas to bring connectivity to places currently not reachable

- eyerise ® liquid crystal for greener windows and innovative building architecture

Monday, March 1, 2021

Welcome to the RASIRC ALD Oxide Wizard

- Direct theoretical comparison between water and hydrogen peroxide

- Allows for rapid screening of possible precursors

- Allows for lower cost precursors to be used where previous water reactivity was too low

- Allows for visualization of precursors to better understand steric hindrance effects

Enter The RASIRC ALD Oxide Wizard HERE!

Tuesday, February 23, 2021

Thermal Atomic Layer Deposition of Gold: Mechanistic Insights, Nucleation, and Epitaxy

Thermal Atomic Layer Deposition of Gold: Mechanistic Insights, Nucleation, and Epitaxy

Pengfei Liu, Yuchen Zhang, Cong Liu, Jonathan D. Emery, Anusheela Das, Michael J. Bedzyk,Adam S. Hock*, and Alex B. F. Martinson*

ACS Appl. Mater. Interfaces 2021, XXXX, XXX, XXX-XXX

Tuesday, January 12, 2021

Semiconductor Materials $50B Market on a Strong Run in 2021

Thursday, December 17, 2020

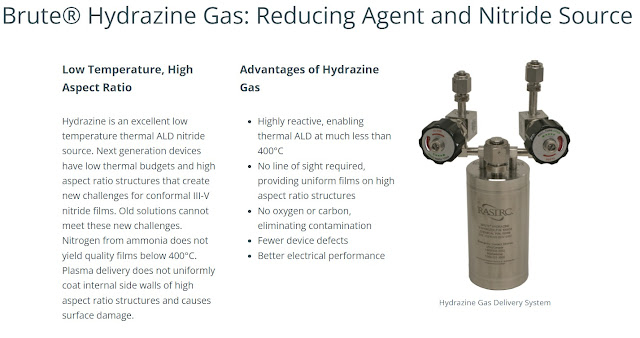

Low Resistivity Titanium Nitride Thin Films ALD realized by RASIRC Brute® Hydrazine vaporization technology

- Relatively cheap precursor, mainly TiCl4 and TDMAT, as compared to the much more expensive precursors with lower vapor pressure for tantalum metal nitrides (PDMAT) and metals like Co (CCTBA) and Ru (RuCp´s).

- High vapor pressure and reactivity allowing fast conformal processing bay both CVD, pulsed CVD and ALD for TiCl4/NH3 based processes

- Possibility to tune low resistivity films however at relatively high temperatures (TiCl4/NH3) not allowing for BEOL thermal budget requirements (<390 °C)

- Excellent barrier properties hindering metal diffusion (TDMAT and TiCl4)

- Metal gate work function tuning by doping and partial controlled oxidation

- Oxygen gettering driving excess oxygen from the gate oxide channel interface into the metal gate reducing the CMOS device EOT.

- Mini Batch and Large Batch processing capability (e.g. TEL Indy, ASM A412, Kokusai ALDina, Picosun Sprinter)

Due to low resistivity, titanium nitride (TiN) thin films are in production as the diffusion barrier for Cu, Co and W as well as the gate metal barrier in CMOS. However, as mentioned, for high aspect ratio features, thermal ALD deposition is needed because of high conformality. Therefore, it is very important to develop thermal ALD TiN processes further to improve the capacitor electrode, barrier and CMOS metal gate properties to perfection.

Cheng-Hsuan

Kuo and co-workers at UCSanDiego in the Kummel research group, has recently concluded a study on TiN ALD utilizing the RASIRC BruteÒ Hydrazine (N2H2) vaporizer technology, which is

presented this week at IEEE SISC December 16-18 (LINK).

In the work, titanium tetrachloride (TiCl4) and anhydrous hydrazine (Rasirc, Brute HydrazineÒ) were employed as the precursors with ultra-high purity nitrogen purge gas.

- The TiN ALD chamber was connected to an in-vacuo Auger Electron Spectrometer (RBD Instruments), which was used to determine the atomic composition of ALD. (Fig. 1)

- The sample was biased at -100V DC and Ar plasma (50W) was used to remove the surface oxides and impurities. (Fig. 2)

- To determine resistivity, four-point probe (Ossila) measurements were performed on TiN thin films on degreased SiO2 substrates. (Fig. 3)

- Scanning electron microscopy (SEM), ellipsometry, and X-ray reflectivity (XRR) were used to measure TiN film thicknesses. (Fig. 4)

To conclude, these experiments indicate that minimizing oxygen concentration is key in producing TiN thin films with desirable electrical properties.

The optimal resistivity of the TiN deposited at 350oC was 160 micro-ohm-cm which is the lowest reported resistivity of any TiN film deposited by thermal ALD. As stated above the importance of 3D process capability can be met by having TiN thin films synthesized by using thermal ALD and post-plasma treatment reducing oxygen concentration and impurities potentially in very high aspect ratio structures such as contact holes, FinFET, Gate all around FETs, vias, DRAM capacitors structures as well as 3DNAND metal gates and contacts.

References

[1] C. H.

Ahn. et al. Metals and Materials International, 7 (2001)

[2] Steven

Wolf et al. Applied Surface Science 462 (2018)

Acknowledgements

This work

was supported in part by the SRC

LINKS

EEE SISC December 16-18 (LINK).

Friday, November 6, 2020

Refreshing Material Advances for Logic, Memory, and Packaging5th CMC Conference "After-Hours" Available up to December 11

Thursday, October 29, 2020

Researchers develop new atomic layer deposition process using ultrasonic precursor evaporation

Monday, August 3, 2020

BDEAS - a versaitile ALD precursor for high quality dilectric films in leading edge semiconductor applications

One of the most important reasons why Silicon (Si), in place of Germanium (Ge), was propelled to the front of the class in the semiconductor industry from the very beginning, is the fact that Si forms a very stable oxide-semiconductor interface with SiO2. A high-quality oxide interface is a key to making field-effect transistors (MOSFETs). Germanium oxide is water-soluble which rendered it useless for MOSFET fabrication in the early days (now the industry is advanced enough to possibly solve that).

Thermal oxidation of Si at temperatures > 800 °C yields SiO2. To avoid such high temperatures and long processing times and tune the material properties, (wet) chemical oxidation, (plasma-enhanced) chemical vapor deposition or sputtering and electron beam evaporation are also preferred methods to grow SiO2. The advantages of precise thickness control, optimal large-area uniformity, and the conformality over demanding substrate topologies of atomic layer deposition (ALD) based SiO2 films, all led to an expansion of target applications such as; spacer based self-aligned double/quadruple patterning (SADP or SAQP) in fabricating DRAM and logic chips (Link), interface engineering between Si and high-k materials (Link), moisture barrier or protective or insulator coatings (Link), nanolaminate structures with tailored optical and electronic properties (Link) and double layer surface passivation in Si photovoltaics (Link), etc. to name but a few.

Bis(diethylamino)silane (BDEAS) [SiH2[N(CH2CH3)2]2, also known as SAM-24[MP1] , is one of the most preferred Si precursors for ALD of SiO2 and other Si-containing films. It’s an air-sensitive, moisture-sensitive, flammable, colorless, and odorless liquid precursor (boiling point 70 °C (30mm), density 0.804), which exhibits a high vapor pressure, i.e. ~100 Torr at 100 °C.

The research group of Prof. W. M. M. Kessels, Department of Applied Physics, Eindhoven University of Technology, has reported that BDEAS is suited for low-temperature synthesis of high-quality SiO2 by ALD with the SiO2 properties being relatively insensitive to the substrate temperature for the temperature range of 100 – 300 °C; for temperatures reaching 400 °C thermal stability issues of the precursor and its ligands start to play a role. The process is also relatively fast as it combines a high growth-per-cycle (0.8 – 1.7 Å/cycle) with relatively short dosing and purge times. The ALD SiO2 processes with BDEAS precursors are therefore of interest for high-volume manufacturing applications, for instance, using ALD batch processes or inline (plasma) ALD equipment.

Strem Chemicals, Inc., a high

purity specialty chemicals manufacturer and supplier, headquartered in

Newburyport, Massachusetts, USA, boasts a vast variety of ALD/CVD precursors, including

BDEAS for depositing Si-based films in different

applications.

Since 1964, Strem Chemicals, Inc. has been serving its clients from academic, industrial, and government research and development laboratories as well as commercial scale businesses in the pharmaceutical, microelectronic, and chemical/petrochemical industries. Strem also provides custom synthesis (including high-pressure synthesis) and current good manufacturing practice (cGMP) services. With ISO 9001 certification for the Quality Management System (QMS) standard and documentation, Strem products are high purity materials, typically 99%, with some at 99.9999% metals purity. Strem utilizes a comprehensive range of analytical techniques tailored to each product to ensure quality because researchers typically rely on the supplier's quality procedures and documentation, which if poorly conducted[MP1] may kill a great research idea. All of Strem's catalogs, since inception, have listed “Color and Form” for every product as primary indicators of quality.

[MP1]SAM-24 may be an Air liquide trademark.

%20(1).png)