Here is a very good text by Mark Lapedus on ALD patterning technology from the Semiconductor Engineering Blog:

Selective deposition may be the way forward to the far reaches of device scaling after 7nm.

APRIL 16TH, 2015 - BY: MARK LAPEDUS

Chip scaling is becoming more difficult at each process node, but the industry continues to find new and innovative ways to solve the problems at every turn. And so chipmakers continue to march down the various process nodes. But the question is for how much longer? In fact, at 16nm/14nm and beyond, chipmakers are finding new and different challenges, which, in turn, could slow IC scaling or bring it to a sudden halt one day.

To prevent those occurrences, chipmakers are working on a multitude of technologies. But one in particular is gaining steam in the lab—selective deposition. Some call the technology ALD-enabled nano-patterning.

At least in theory, selective deposition is a paradigm shift in chip manufacturing that could help extend IC scaling. But researchers still have some issues to solve to make this technology viable. And even then, it is not expected to appear until 7nm or 5nm.

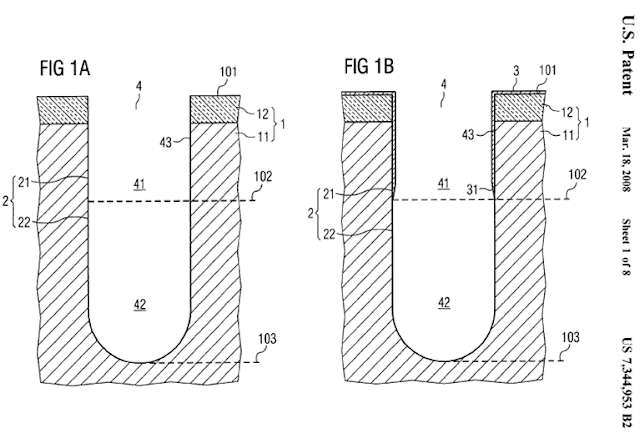

For decades, chipmakers have used deposition, which is a process that deposits a blanket of thin material on a surface. In contrast, combining novel chemistries with atomic layer deposition (ALD) or molecular layer deposition (MLD) tools, selective deposition involves a process of depositing materials and films in exact places. Selective deposition can be used to deposit metals on metals and dielectrics on dielectrics on a device.

Continue reading : http://semiengineering.com/new-patterning-paradigm/

Please also do check out this Review, that I have blogged about before, by Prof. Kessels et al on this topic!

A. J. M. Mackus, A. A. Bol and W. M. M. Kessels

Nanoscale, 2014,6, 10941-10960

DOI: 10.1039/C4NR01954G, Review Article

Atomic layer deposition (ALD) is a method that allows for the deposition of thin films with atomic level control of the thickness and an excellent conformality on 3-dimensional surfaces. In recent years, ALD has been implemented in many applications in microelectronics, for which often a patterned film instead of full area coverage is required. This article reviews several approaches for the patterning of ALD-grown films. In addition to conventional methods relying on etching, there has been much interest in nanopatterning by area-selective ALD. Area-selective approaches can eliminate compatibility issues associated with the use of etchants, lift-off chemicals, or resist films. Moreover, the use of ALD as an enabling technology in advanced nanopatterning methods such as spacer defined double patterning or block copolymer lithography is discussed, as well as the application of selective ALD in self-aligned fabrication schemes.

%20(1).png)