The Emergence of Hydrazine (N2H4)

in Semiconductor Applications

by Jeffrey

Spiegelman and Daniel Alvarez

Purpose

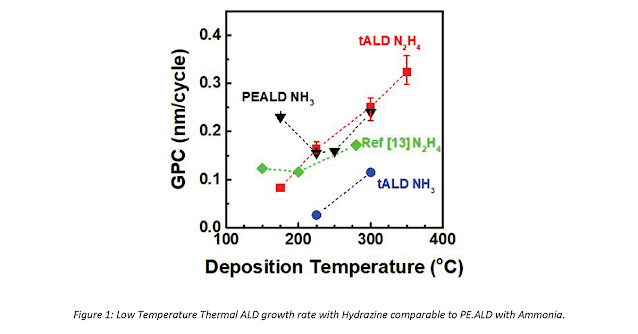

Historically, metal-nitride

MOCVD and ALD films have been fabricated with Ammonia (NH3). However, lower thermal budgets and shrinking 3-dimensional

structures are needed for next generation semiconductor devices. These challenges have exposed limitations

with ammonia which could be overcome by replacing ammonia with hydrazine (N2H4). Purity of commercially available hydrazine has delayed its adoption. RASIRC Inc. has recently developed a new

formulation of hydrazine called BRUTE® Hydrazine which is safer and meets

purity requirements for semiconductor manufacturing. Prior to Brute Hydrazine,

the body of technical data applicable to semiconductor processing was limited

and scattered. This paper provides an

overview of the growing activity in the thin film use of Brute hydrazine as

well as early references on laboratory grade hydrazine for historical

completeness.

Increasing

Need for More Reactive Nitrogen Sources

Emerging devices

such Logic and Advanced Memory require high quality thin (5-20 Å) electrode and

barrier films. Difficult thermal budget

constraints are now being placed on well-known materials such as SiNx,

TiNx and TaNx.1-3 Deposition temperature limitations have dropped

to 350°C and below while very low resistivity (<150 micro-ohm/cm) for TiN

and TaN must still be achieved. Although

metal and nitride films grown using plasma assisted processes (PE-ALD) and

(PE-CVD) at low temperatures exhibit enhanced properties, the damage induced by

plasma on sensitive substrates is one of the common drawbacks,4,5 as

well as inability to support HAR or three-dimensional structures like

horizontal vias and deep trenches.

III-V Nitride

devices require a more reactive nitrogen source to reduce deposition

temperatures and increase compositional stability.

6 Growth rates for

InGaN films deposited with ammonia at reduced temperatures are prohibitively

slow and grossly inefficient in ammonia usage. A more reactive nitrogen source

can enable acceptable deposition rates at 500-650° C, where alloy stability is

significantly increased and nitride source to precursor ratio can be reduced.

In addition to

growing thin nitride films, hydrazine can also act as a reducing agent for

several late transition-metals. This

work is highly relevant to the use of hydrazine as a surface cleaning agent as

well as a potential adder for metal ALD.7

Figure 1: Low Temperature Thermal ALD growth rate

with Hydrazine comparable to PEALD with Ammonia.

The following table

provides primary references for the areas of hydrazine ALD/CVD relevant to

Semiconductor device applications.

Additional relevant references on related films are also included.

|

Precursor and

Temperature

|

Film

|

Reference

|

|

Al surface nitridation

200C-450C

|

AlN

|

Taylor

et.al. U.S. Patent 6465350, 2002

|

|

TMA MOCVD

300C-400C

|

AlN

|

Fujieda, S. et. al. Adv.

Func. Mat. 1996, 6(3), 127-134

|

|

TDEAA 150C-225C

|

AlN

|

Abdulagatov, A.I. et. al. Russian Microelectronics, 2018,

47(2), 118–130.

|

|

TMA 175C-350C

|

AlN

|

Jung, Y.C. et. al. Materials 2020, 13, 3387;

https://doi:10.3390/ma13153387

|

|

TDMAA 225C-400C

|

AlN

|

Ueda, S.T. et. al. Appl.

Surf. Sci. 2021, 554, 149656

|

|

BCl3 ,

350C

|

BN

|

Wolf, S. et. al. Appl. Surf. Sci. 2018, 439, 689–696

|

|

Surface Clean

200C

|

Cu

|

Hwang, S.M. et.

al. ECS Trans. 2019, 92, 265

|

|

Surface Clean 100C-300C

|

Cu, Co

|

Hwang, S.M. “Effect of

Surface Cleaning Efficacy on Vapor-Phase Cleaning of Cu and Co Using Anhydrous

N2H4” AVS ALD/ALE 2021 Session: Area Selective ALD AS4-1

|

|

TMG, 400C-800C

|

GaN

|

Fujieda, S. et.

al. Jpn. J. Appl. Phys. 1987,

26, 2067-2071

|

|

TMG, TMI, 600C-900C Theoretical

|

GaN, InGaN

|

Koukitu, A. et. al. phys. Stat. sol. (b), 1999,

216(1), 707-712

|

|

TMG

Theoretical

|

GaN

|

Goddard, W. et.al. J. Phys. Chem. C 2015, 119(8) 4095–4103

|

|

[Ru(DMBD)(CO)3]

200C. Metal Deposition

|

Ru

|

Cwik, S. et. al. J. Vac. Soc. Sci. & Tech. A 2020, 38, 012402; https://doi.org/10.1116/1.5125109

|

|

SiH4 550C-1050C

|

SiN

|

Yoshioka, S. et. al. J.

Electrochem. Soc. 1967, 114, 962–964.

|

|

SiH4/W hot wire 300C

|

SiN

|

Matsumura, H. 1989 Jpn. J. Appl. Phys. 28 2157

|

|

Si2H6,

Si3H8

350C-550C

|

SiN

|

Kanoh, H. et al. “Low-Temperature Chemical-Vapor-Deposition of

Silicon Nitride” Journal de Physique IV

Proceedings, 1991, 02 (C2),

pp.C2-831-C2-837.

|

|

Si surface Nitridation.

300C-500C

|

SiN

|

Abyss, J.A.

et. al. J. AIChE 1995,

41, 2282–2291

|

|

Si2Cl6 285C

|

SiN

|

Edmonds, M. et. al., J. Chem. Phys. 2017, 146,

052820 ; https://doi.org/10.1063/1.4975081

|

|

Si2Cl6 320C-410C

|

SiN

|

Kondusamy,

A. et.

al. “Low Temperature Thermal ALD

of Silicon Nitride Utilizing a Novel High Purity Hydrazine Source”, Electrochem. Soc. AiMES 2018, Meet.

Abstr. G02-993

|

|

Si2Cl6 410C-650C

|

SiN

|

Le, D.N. et al “Thermal Atomic Layer Deposition

of Silicon Nitride Using Anhydrous Hydrazine and Ammonia” AVS ALD 2021, Session AF9.

|

|

TBTDET 150C-250C

|

TaN

|

Burton, B.B., et. al. J. Electrochem. Soc. 2008,

155, D508

|

|

TBTDET 100C-300C

|

TaN

|

Wolf, S. et.al. Appl.

Surf. Science, 2018, 462,

1029-1035

|

|

TDMAT 200C

|

TiN

|

Wierda, D.A. et. al. Electrochemical and Solid-State

Letters, 1999, 2 (12) 613-615

|

|

TiCl4 200C-350C

|

TiN

|

Abdulagatov,

A.I. Ph.D. Thesis, Univ. of Colorado, 2012, UMI No.

3549153

|

|

TiCl4

300C-400C

|

TiN

|

Wolf, S. et.al. Appl.

Surf. Science, 2018, 462,

1029-1035

|

|

TiCl4 300C-400C

|

TiN

|

Kuo, C.H. et. al. “Low Resistivity Titanium Nitride Thin Film Fabricated by Atomic Layer

Deposition on Silicon”

AVS ALD 2021, Session

AM5-9.

|

|

TiCl4

250C-400C

|

TiN

|

Alvarez, D. et. al. “Comparative Study of Titanium Nitride ALD

using High Purity Hydrazine vs Ammonia” Electrochem.

Soc. 2020 Meet. Abstr. MA2020-02 1668

|

|

BTBMW

300C

|

WN

|

Bernal-Ramos, K.

Ph.D.

Thesis, Univ. of Texas, Dallas, 2014,

UMI No. 3668896

|

|

BTBMW

250C-350C

|

WN

|

Le, D.N. et.al.

“Atomic Layer Deposition of Nanometer Thick Tungsten Nitride Using Anhydrous

Hydrazine for Potential X-Ray Optics Application” AVS ALD/ALE 2021

Session: AF10-15

|

Discussion

on Specific Films

Titanium

Nitride (TiN) is a critical film in semiconductor

manufacturing. Commonly TiN is utilized as an electrode material as well as a

low resistivity barrier layer. Early CVD

work by Wierda demonstrated low temperature (50C-250C) TiN CVD by hydrazine and

TDMAT. Optimal results were obtained

when 1.9% hydrazine was combined with ammonia.

This may be attributed to a different mechanistic pathway or ammonia

dilution of oxygen containing contaminants.

Wolf later demonstrated low temperature (300C) TiN ALD with the use of

TiCl4. This result was then optimized by Kuo in the same lab, where

resistivities well below 180 micro-ohm/cm were achieved by reducing oxygen

contamination in the film through improved hydrazine purity. A comparative

study of Hydrazine vs Ammonia for TiCl4 was reported by Taiyo Nippon

Sanso, where the two nitrogen sources showed highly disparate growth rates and

film properties. Hydrazine demonstrated

viability at the 250C-400C range for low temperature semiconductor

applications.

Silicon

Nitride (SiN) is a widely used material in

semiconductor devices. SiN is commonly used as an etch stop, a dielectric

layer, an encapsulation layer, and as a barrier layer on organic devices. As early as 1967, hydrazine and Silane CVD

was demonstrated at 550C. This work was

then followed-up by Kanoh with higher silanes in the 350C-550C range. In a very interesting approach, Abyss

demonstrated Si surface nitridation with hydrazine at temperatures as low as

300C. More recently, Edmonds cleverly

used hydrazine/hexachlorodisilane ALD to place a thin SiN passivation layer on

SiGe at 285C. Extensive studies have

been carried out by the Kim group at UT Dallas in the range of 320C-650C. Below 400C, thermal ALD leads to films with

good composition, but unfavorable low density and high wet etch rates. This can be overcome with addition of Argon

plasma densification. At 480C and above,

thermal ALD films are grown with high density, low wet etch rates, and reduced

hydrogen incorporation. When compared to

ammonia grown films in the same temperature range, the hydrazine ALD films are

superior up to temperatures >600C where films properties become more

similar.

Gallium

Nitride and Indium Gallium Nitride (GaN, InGaN) grown

with hydrazine have had few publications in the last 20 years despite interest

in reduction of ammonia usage and poor indium incorporation. These films are

central in LEDs and emerging power devices.

Fujieda demonstrated that overall chemical consumption can be greatly

reduced with hydrazine vs ammonia for GaN deposition in the 400C-800C

range. Koukitu followed this up with a theoretical

thermodynamic study showing how the use of hydrazine can reduce deposition

temperature and stabilize composition for GaN and InGaN films. In 2015, Goddard elucidated the likely

mechanisms for hydrazine vs ammonia is GaN deposition.

Though little

has been published for GaN/InGaN deposition with hydrazine, viability for III/V

materials can be inferred from work published for AlN ALD with hydrazine. Fujieda reported MOCVD with trimethyl

aluminum (TMA) in the 300C-400C range.

More recently Jung reported ALD with TMA as low as 175C and compared to

ammonia in the 175C-350C range. Abdulagatov made use of the nitride-based

ligands with TDEAA/hydrazine ALD in the 150C-250C range. In a similar approach using TDMAA, Ueda has

reported the deposition of crystalline AlN films as low as 350C with thermal

ALD. With the addition of Argon plasma densification,

crystalline films can be obtained as low as 225C, where crystallinity in AlN

was optimized at 400C.

Copper,

Cobalt and Ruthenium can be reduced in situ by Hydrazine. Furst provided a detailed review on hydrazine

as a reducing agent for organic compounds.8 Recently Hwang reported

an extension of this reactivity to Cu surfaces.

Gas phase reduction of Cu oxides to Cu metal with hydrazine at moderate

temperatures (100C-300C) was reported.

Here, hydrazine is introduced in short pulses, analogous to an ALD

reaction. A similar report for Cobalt has also been presented by Hwang. Cwik working in the Winter group has recently

released data showing the ability to grow Ru metal using hydrazine as a

reducing agent in Ru ALD at 200C. Here

hydrazine was found to be advantageous over substituted hydrazine derivatives.

Conclusion

Hydrazine is

emerging as a replacement for ammonia in low temperature applications. Recent

examples of different production-worthy nitrides have been reported for both

ALD and MOCVD films. These positive

reports have led to an increasing level of interest within the scientific community

looking for solutions to new device structures and increased density.

Contact

the Author

The author is

available for additional technical discussion. Contact

RASIRC to schedule an appointment.

References

1. Burton BB, Lavoie AR, George SM (2008) Tantalum nitride atomic layer deposition using (tert-Butylimido) tris(diethylamido)tantalum and Hydrazine. J Electrochem Soc 155, D508

2. Alvarez, D.; Spiegelman, J.; Andachi, K.; Holmes, R.; Raynor, M.; and Shimizu, H. Enabling Low Temperature Metal Nitride ALD Using Ultra-High Purity Hydrazine: ET/ID: Enabling Technologies and Innovative Devices. 2017 28th Annu. SEMI Adv. Semicond. Manuf. Conf., Saratoga Spring, NY, USA, 2017, 426–430.

3. Hwang, S.M.; Kim, H.S.; Le, D.N.; Ravichandran, A.V.; Sahota, A.; Lee. J.; Jung, Y.C.; Kim, S.J.; Ahn, J.; Hwang, B.K.; Lee, L.; Zhou, X.; and Kim, J. Plasma-Enhanced Atomic Layer Deposition of Nanometer-Thick SiNx Films Using Trichlorodisilane for Etch-Resistant Coating. ACS Appl. Nano Mater. 2021, 4, 2558–2564. https://doi.org/10.1021/acsanm.0c03203.

4. Kim, H.; Oh, I.-K.; Review of Plasma-Enhanced Atomic Layer Deposition: Technical Enabler of Nanoscale Device Fabrication. Jpn. J. Appl. Phys. 2014, 53, 03DA01.

https://doi.org/10.7567/JJAP.53.03DA01.

6. Ravinder Kour et al 2020 ECS J. Solid State Sci. Technol. 9, 015011

7. Hwang, S. M.; Peña, L. F.; Tan, K.; Kim, H. S.; Kondusamy, A. L. N.; Qin, Z.; Jung, Y. C.; Veyan, J.-F.; Alvarez, D.; Spiegelman, J.; et al. Vapor-Phase Surface Cleaning of Electroplated Cu Films Using Anhydrous N2H4. ECS Trans. 2019, 92, 265–271.

8. Furst, A. et. al. Chem. Rev. 1965, 65, 51–68.

%20(1).png)