Ruthenium has been under investigation for years among researchers all across the globe for applications such as high-work function electrodes in dynamic random access memory (DRAM) capacitors or gate stack in p-channel metal oxide semiconductor (MOS) in the front end of line (FEOL). It has also been considered for alloyed diffusion barriers, adhesion layers or seed layers in interconnects or through silicon vias (TSVs) for direct electrochemical deposition of copper in the back end of line (BEOL). In these applications, atomic layer deposition based on ultra-thin Ru films offer unique advantages.

Most of the available Ru ALD or CVD precursors have issues concerning low vapor pressure and high impurity levels, such as carbon and oxygen, which get incorporated in the films. In addition to that, long incubation times impacting throughput and process controllability, poor film adherence, and non-uniformity in high-aspect-ratio structures are some critical limitations of the field. However, Strem Chemicals—a high purity specialty chemicals’ manufacturer and supplier—offers a well-preferred bis(ethylcyclopentadienyl)ruthenium(II) [[(CH3CH2)C5H4]2Ru] (

catalog number 44-0040) precursor for depositing Ru based ALD/CVD films for niche applications, such as aligned RuO2 nanorods. The pale yellow liquid precursor with a density of 1.3412 and vapor pressure ~0.2mm (85°C), is sold pre-packed in ALD cylinders by Strem Chemical. These fit many of the ALD tools on the market as well as many custom laboratory designed tools.

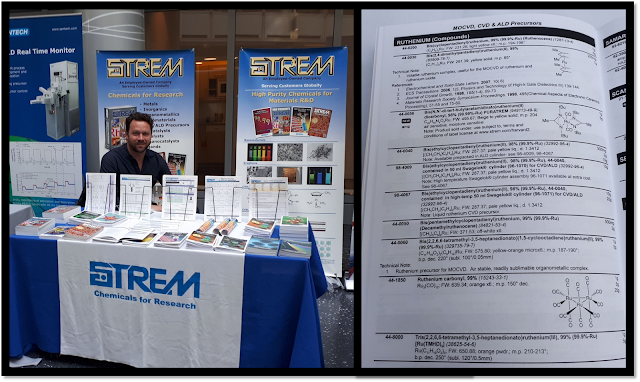

Recently, (March 19-20, 2019) Strem exhibited at the annual EFDS ALD for Industry Workshop in Berlin, Germany and we had a chance to discuss Ruthenium precursors with attendees. Here is a short section from the well-known Strem ALD/CVD Precursor Catalogue.

Here are just a few examples of thermal as well as plasma driven thin film deposition processes based on bis(ethylcyclopentadienyl)ruthenium(II) precursor presented by the diverse group of researchers at this meeting.

Thomas Waechtler et. al. have reported plating results on layers of ALD Cu with underlying Ru deposited using bis(ethylcyclopentadienyl)ruthenium(II) outperforming ones achieved on PVD Cu seed layers with respect to morphology and resistivity. Application of these processes suggest that a combination of ALD Cu with PVD or ALD-grown Ru could significantly improve the ECD Cu growth.

Researchers from the National Taiwan University of Science and Technology studied structures and electrochemical capacitive properties of RuO2 vertical nanorods encased in hydrous RuO2. They grew vertically aligned RuO2 nanorods with an aspect ratio in the range of 28-30 on the LiNbO3(100) substrate via metal-organic CVD (MOCVD) using bis(ethylcyclopentadienyl)Ru from Strem Chemicals. (

Link)

A

Korean research group has also reported plasma-enhanced ALD of Ru thin films performed using an alternate supply of bis(ethylcyclopentadienyl)ruthenium and NH3 plasma, where NH3 plasma acted as an effective reducing agent for bis(ethylcyclopentadienyl)ruthenium. The process exhibited no carbon or nitrogen impurities in the film as determined by elastic recoil detection time of flight analysis and the film density was found to be higher than that found in conventional oxygen based ALD.

Since 1964, Strem Chemicals, Inc. has been serving its clients from academic, industrial and government research and development laboratories as well as commercial scale businesses in the pharmaceutical, microelectronic and chemical/petrochemical industries. Strem (Headquarters: Newburyport, Massachusetts, USA) is a high quality specialty chemicals’ manufacturer and supplier. Strem also provides custom synthesis (including high-pressure synthesis) and current good manufacturing practice (cGMP) services. With ISO 9001 certification as a Quality Management System (QMS) standard with documentation, most of Strem’s products are reliable and of high purity, typically 99%, with some having 99.9999% metals purity. Strem utilizes a comprehensive range of analytical techniques tailored and applied to each product to ensure quality because the researchers typically rely on a supplier's quality procedures and documentation, which if poorly conducted may kill a great research idea. All of Strem's catalogs, since inception, have listed “Color and Form” for every product as a primary indicator of quality.

More than fifty years of experience in manufacturing inorganic and organometallic chemicals has enabled Strem to expand its product offering of MOCVD, CVD, and ALD precursors to continually add new products in support of this dynamic and exciting field. Strem’s CVD & ALD product range includes:

---

Promotional Blog for Strem Chemicals, Inc.

Researched, produced & written by BALD Engineering AB, Stockholm, 2019-04-10

Abhishekkumar Thakur, Jonas Sundqvist

www.baldengineering.com