STREM Chemicals offers one of the most promising ruthenium amidinate precursors for growing Ru ALD or CVD films

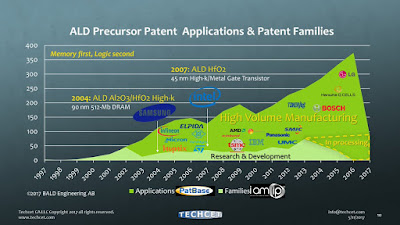

The saturation of Moore’s curve while following systematic downscaling of logic and memory devices has given rise to the biggest challenges involving contacts and interconnects in the chip. The transistors (FinFETs at leading nodes) are getting better and better at smaller dimensions. On the contrary, the shrinking interconnects and contacts at each technology node cause the unwanted resistance-capacitance (RC) delay to increase. Therefore, the chipmakers are exploring new materials to replace conventional tungsten and copper for contacts and interconnects, respectively (see figure below, LINK). At 10 nm, Intel switched over to cobalt for contacts and some, but not all, interconnect layers. Ru is also being explored hugely since Co has some trade-offs as well as higher line resistance (VLSI 2017, Globalfoundries). In fact, there was also news in the market regarding use of Ru implemented in Intel’s 10 nm technology node (TechInsight 2018).

Intel 10nm mid end of line cobalt and copper 12 layer metallization as presented at IEDM December 2017 pre-announcement (LINK, Press kit).

Ru is also an excellent candidate for the electrode capacitor in DRAM applications and gate electrode material in CMOS transistor applications because of its high melting point, high oxidation resistance, and low resistivity. Ruthenium’s lower resistivity and ease of dry etching give it a significant advantage over other noble metals like iridium and platinum. Ru seed-layer deposited as a conformal via liner significantly improves copper adhesion and hinders oxygen diffusion in interconnects and through-silicon-via (TSV) applications. Moreover, ruthenium oxide is conductive and therefore, oxygen diffusion from adjacent materials or processes does not hinder the device performance. Recent research reports the use of ruthenium-based materials as an electrode in ferroelectric applications as well.

Thus, as the main bottleneck of next generation ICs, interconnects and contacts are nowadays the major driving factors of the market of high quality specialty chemicals for the performance or function specific materials or molecules. The physical and chemical properties of a single molecule or a formulated mixture of molecules as well as its chemical composition influence the end product performance extensively. Therefore, unlike the other sub-sectors of the chemical industry, the companies manufacturing and marketing specialty chemicals provide more often than not targeted customer service to innovative individual technical solutions for their customers.

Since 1964, Strem Chemicals, Inc. has been serving its clients from academic, industrial and government research and development laboratories as well as commercial scale businesses in the pharmaceutical, microelectronic and chemical / petrochemical industries. Strem (Headquarters: Newburyport, Massachusetts, USA) is a high purity specialty chemicals’ manufacturer and supplier. Strem also provides custom synthesis (including high pressure synthesis) and current good manufacturing practice (cGMP) services. With ISO 9001 certification for Quality Management System (QMS) standard and documentation, most of the Strem’s products are reliably of high purity, typically 99%, with some at 99.9999% metals purity. Strem utilizes a comprehensive range of analytical techniques tailored to each product to insure quality because the researchers typically rely on the supplier's quality procedures and documentation, which may kill a great research idea if poorly conducted. All of Strem's catalogs, since inception, have listed “Color and Form” for every product as primary indicators of quality.

More than fifty years of experience in manufacturing inorganic and organometallic chemicals has enabled Stem to expand its product offering of MOCVD, CVD, and ALD precursors. They are continually adding new products for this dynamic and exciting field. Strem’s product range includes:

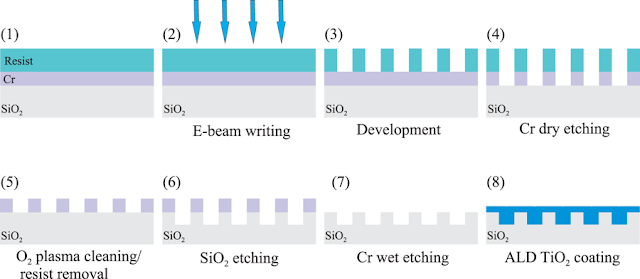

Most of the available Ru ALD or CVD precursors have issues concerning low vapor pressure and high impurity levels, such as carbon and oxygen, which get incorporated in the films. In addition to that, long incubation times impacting throughput and process controllability, poor film adherence, and non-uniformity in high-aspect ratio structures are some critical limitations of the field. However, ruthenium amidinate precursors such as Bis(N,N’-di-t-butylacetamidinato)ruthenium(II) dicarbonyl (catalog number 44-0056) and others are some of the most promising precursors finding a home in Strem’s product catalog for growing ALD and CVD films. Each amidinate ligand chelates the metal center through two metal-nitrogen bonds. These relatively weak M-N bonds and strong byproduct N-H bonds lead to lower ALD growth temperatures. However, the M-N bonds are strong enough to provide stability to the precursor at the standard temperatures used. Also, since the amidinate ligands chelate to the metal center, they are thermally stable yet have high and self-limited reactivity to water vapor which is essential for ALD. Amidinates do not have any oxygen-metal bonds thus enabling the deposition of metallic films with very low oxygen content in the film and at the interface with the sub-layer.

ALD thin-films deposited using

Bis(N,N’-di-t-butylacetamidinato)ruthenium(II) dicarbonyl exhibit high

conductivity, density and purity. Atomic probe microscopy measurements

revealed nearly carbon free crystallites with far less carbon impurity segregated

near the grain boundaries. The films also showed very good conformality

even inside the trenches with aspect ratios (~40:1) possessing strong adhesion. The

precursor was found to be thermally stable in a bubbler at 130°C for months and

showed very clean TGA vaporization with only trace residue (0.2%).

---

Promotional Blog for Strem Chemicals, Inc.

Researched, produced & written by BALD Engineering AB, Stockholm, 2018-10-30

Abhishekkumar Thakur, Jonas Sundqvist

www.baldengineering.com

Promotional Blog for Strem Chemicals, Inc.

Researched, produced & written by BALD Engineering AB, Stockholm, 2018-10-30

Abhishekkumar Thakur, Jonas Sundqvist

www.baldengineering.com

%20(1).png)