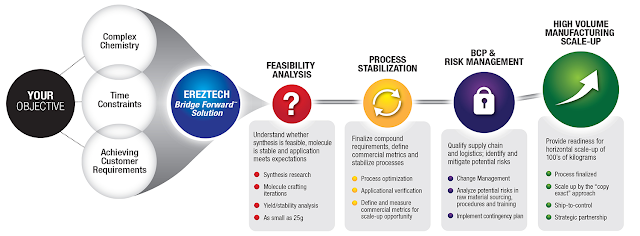

EREZTECH introduces Bridge ForwardTM solution - from synthesizing complex molecules with feasibility analysis to executing a scalable route to high volume manufacturing

Nowadays, leading technology nodes for Logic, DRAM, and NAND/3D NAND rest upon continuously increasing use of ALD & CVD in HVM. The basic layers and their applications, products and respective precursors are listed in the table below:

This involves a huge mix of resources including stakeholders within the fab organizations as well as external partners and suppliers from the supply chain, ranging from universities and research institutes to material suppliers, chemical and gas companies, wafer processing equipment and sub-component manufacturers, and companies facilitating R&D for the semiconductor industry.

Nowadays, leading technology nodes for Logic, DRAM, and NAND/3D NAND rest upon continuously increasing use of ALD & CVD in HVM. The basic layers and their applications, products and respective precursors are listed in the table below:

| Layer | Application | Product | Precursors (examples) |

| Al2O3 | High-k, liner, etch stop, mask | Logic, DRAM, NAND | TMA, AlCl3 |

| HfO2 | High-k, mask | Logic, DRAM | HfCl4, TEMAHf, Hf-Cp´s |

| ZrO2 | High-k, mask | Logic, DRAM | ZrCl4, TEMAZr, Zr-Cp´s |

| La2O3 | High-k | Logic | La(THD)3 |

| TiN | Electrode, barrier, mask | Logic, DRAM, NAND | TiCl4, TDMAT, TEMAT |

| TaN | Electrode, barrier | Logic, DRAM | TaF5, TaCl5, PDMAT |

| Co | Barrier/seed, contact | Logic | CTTBA, CoCOCp |

| Ru | Electrode, barrier/seed, contact | Logic, (DRAM) | RuCp´s, RuO4 |

| W, WN, WC | Electrode, barrier/seed, contact | Logic, DRAM, NAND | WF6, WCl6, W-MO |

This involves a huge mix of resources including stakeholders within the fab organizations as well as external partners and suppliers from the supply chain, ranging from universities and research institutes to material suppliers, chemical and gas companies, wafer processing equipment and sub-component manufacturers, and companies facilitating R&D for the semiconductor industry.

This involves a huge mix of resources including stakeholders within the fab organizations as well as external partners and suppliers from the supply chain, ranging from universities and research institutes to material suppliers, chemical and gas companies, wafer processing equipment and sub-component manufacturers, and companies facilitating R&D for the semiconductor industry.

Few companies are capable of creating new molecules from the conception and then bringing it into HVM ; EREZTECH is one of these companies with proven track record in the semiconductor industry.

Being a single source from R&D to HVM, EREZTECH enables clients to achieve thorough control and enhanced visibility, and also helping accelerate the organometallic project.

Leveraging the Ereztech Bridge Forward™ solution, they specialize in collaborating with results-driven clients to achieve long-term project success. From synthesizing complex molecules with feasibility analysis to executing a scalable route to high volume manufacturing.

As mentioned above, a key to success in organometallic R&D is a risk-sharing partnership. Ereztech has a network of 50+ experienced research chemists specialized in the synthesis of custom metal-organics. Having developed 500 new methods for organometallic synthesis, the EREZTECH research team continues to enrich their catalog with 800+ high purity compounds, including:

- Acetates

- Acetylacetonates

- Alkenes/Dienes

- Carbonyls

- Cyclopentadiene derivatives

- Metal-alkyl and –hydride bonds

- Phosphine

Ereztech’s Bridge Forward™ solution is a proven process for helping clients achieve project objectives with successfully synthesizing and scaling-up complex chemicals. After developing on-demand custom precursor, their solution incorporates the following key steps:

- Deliver 25 g of test batches for thorough review and feasibility analysis.

- Produce pilot batches to further refine the compound to meet your purity standards and specifications.

- Develop pre-production ramp-up, including vetting of supply chain partners and optimization of logistics

- Produce high volumes (e.g., thousands of kilograms) of metal-organics to defined project specifications and our stringent ship-to-control standards.

After a detailed and thorough approval process, sometimes change in unavoidable - for instance, change in regulations or a replacement of a supplier.

EREZTECH stays prepared for the potential change required with their comprehensive Change Management Program that:

EREZTECH stays prepared for the potential change required with their comprehensive Change Management Program that:

- Minimizes undesirable impacts on manufacturing systems, with special care for reliability and stability of production processes.

- Ensures the thorough technical review and accuracy of all modifications — and their test procedures — prior to making any changes.

- Maximizes staff planning for a smooth change transition, including employee training before the change is implemented.

Recent examples of precursor scale-ups attained by EREZTECH include:

%20(1).png)