The escalating

struggle with further scaling of integrated circuit chips, on account of

certain feature sizes in advanced chips gradually hitting atomic dimensions,

has compelled the semiconductor industry to become more welcoming to new

materials as a possible solution to continued PPAC

(Power-Performance-Area-Cost) improvement. Traditionally not so popular in the

semiconductor industry, Magnesium (Mg) is being explored for use in various

related applications due to the fact that it forms semiconductor compounds with

oxygen, sulfur, selenium, and tellurium.

For example, Magnesium

Oxide (MgO) is a semiconductor with a wide band-gap and semi-insulating

properties. A very thin semi-insulating MgO layer between two metallic

ferromagnetic layers is used as a “magnetic tunnel junction”. Magnetic

tunneling junctions (MTJs) based on the CoFeB/MgO/CoFeB layer have received

great attention as a promising candidate for future spin logic devices. Among

various applications of MTJs, spin-transfer-torque magnetic random access

memory (STT-MRAM) is emerging as a strong candidate as a next-generation

nonvolatile memory due to its simple integration scheme, low voltage operation,

and high speed. To fulfill certain critical requirements of 3D MTJ based sub-20

nm, high-density STT-MRAM, Samsung Advanced Institute of Technology (SAIT),

Korea, has recently investigated both thermal and plasma-enhanced ALD for

depositing a MgO tunnel barrier using bis(cyclopentadienyl)magnesium precursor

under the scope of the Industrial Strategic Technology Development Program

(10041926, Development of high-density plasma technologies for the thin-film

deposition of nanoscale semiconductors and flexible-display processing) funded

by the Ministry of Knowledge Economy (MKE, Korea). (Link)

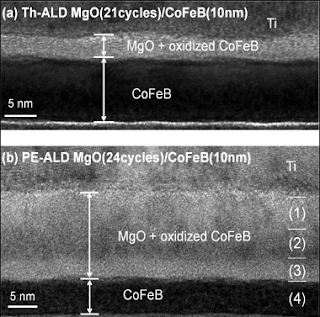

Figure

1. TEM images of (a) Thermal ALD MgO, (b) PE-ALD

MgO grown at 300 °C on a CoFeB layer

Recently,

Panasonic Corporation, Japan, together with the National Institute of Material

Science, Japan, reported ALD based Magnesium Phosphate (MgPO) thin-films as magnesium-ion

conducting solid-state electrolytes that are considered to be promising candidates

for future energy storage and conversion devices. The deposition was carried

out at lower deposition temperatures, ranging from 125 to 300 °C, using

bis(ethylcyclopentadienyl)magnesium. (Link)

Apart from

semiconductor and energy storage applications, Mg is also an interesting

candidate for astronomical and optical applications. For example, recent NASA

missions that make observations in the ultraviolet, such as the Hubble Space

Telescope and the Galaxy Evolution Explorer, employed primary mirrors coated

with aluminum and further protected by thin films of Magnesium Fluoride (MgF2).

Therefore, the Jet Propulsion Laboratory, California Institute of Technology,

under a contract with NASA, reported ALD of MgF2 using bis(ethylcyclopentadienyl)magnesium supplied by Strem Chemicals, Inc. (Link)

Figure

2. Photograph of a concave mirror and convex

diffraction grating for a next-generation UV instrument prototype coated with

electron beam evaporated aluminum and a protective coating of 10 nm ALD MgF2

deposited at 150 °C.

Strem Chemicals, Inc., a leading fine

chemicals supplier, headquartered in Newburyport, Massachusetts, USA, offers the

most preferred precursors worldwide for ALD of Mg-based compounds, i.e, bis(ethylcyclopentadienyl)magnesium [Mg(CpEt)2] (catalog

number 12-0510). The colorless to pale

yellow liquid phase precursor with a density of 0.95 g/cm3 at 20 °C

and vapor pressure of 0.0315 Torr is also sold by Strem Chemicals as pre-packed

in cylinders:

§ 98-4006: Bis(ethylcyclopentadienyl)magnesium,

min. 98%, 12-0510, contained in 50 ml Swagelok® cylinder (96-1070) for CVD/ALD

§ 98-4010: Bis(ethylcyclopentadienyl)magnesium, min.

98%, 12-0510, contained in high-temp 50 ml Swagelok® cylinder (96-1071) for

CVD/ALD

About Strem

Chemicals: Strem is an

employee-owned fine chemicals supplier, manufacturing and marketing

high-quality specialty chemicals for more than half-a-century. They provide

custom synthesis and FDA inspected current good manufacturing practice (cGMP)

services to its clients from academia as well as industry and also to

government R&D labs. What distinguishes Strem from the other chemical

suppliers are its ISO 9001 Quality Management System (QMS) standard and

documenting procedures including for example “Color and Form” for every product

as listed in the product details as a quality indicator for researchers. This

helps Strem deliver precursors with a minimum metals purity of 99%, with some some metal precursors attaining as high as

99.9999% metal’s purity. Strem offers over 5,000 specialty products in the area

of metals, inorganics, organometallics, and nanomaterials. Strem’s product

range includes:

Products Mentioned in this Blog:

98-4006: Bis(ethylcyclopentadienyl)magnesium,

min. 98%, 12-0510, contained in 50 ml Swagelok® cylinder (96-1070) for CVD/ALD

98-4010:

Bis(ethylcyclopentadienyl)magnesium, min. 98%, 12-0510, contained in high-temp

50 ml Swagelok® cylinder (96-1071) for CVD/ALD

Related Product Lines & Resources:

----------

Promotional blog written and researched by Abhishekkumar Thakur and Jonas Sundqvist, BALD Engineering AB

%20(1).png)