BROOMFIELD, Colorado – Nov. 4, 2016 – Today, ALD NanoSolutions (ALD

Nano), the pioneer and market leader in Atomic Layer Deposition (ALD)

technology on particles, reported a banner year on multiple fronts. The

company partners with leading global materials companies to

commercialize ALD advanced materials that significantly improve the

performance, safety and other characteristics of end products in

industries like lighting, batteries, sensors, life sciences and

catalysts. 2016 highlights include new patents, deeper customer

engagements, expanded manufacturing space, and new reactors to increase

production capacity. The momentum illustrates how ALD Nano is harnessing

the immense near-term market opportunities for its proprietary ALD

technologies outside of ALD’s traditional deployment in the

semiconductor industry.

Leading with Differentiated Intellectual Property (IP)

Major 2016 milestones reinforced ALD Nano’s pioneering development

and leadership in ALD for control of surface properties at the atomic

level for unique functionality of particles and other materials. The

company obtained new patents, including some from the University of

Colorado Boulder (CU Boulder), its R&D partner since inception. This

brings ALD Nano’s total patent holdings to 28 issued and 14 pending.

The new IP heightens the market value and cost-effective use of its

“Particle ALD” and “Polymer ALD” to create advanced materials.

An important new patent1 covers an ALD method to deposit

inorganic films on organic polymer surfaces. For industries like OLED

displays and lithium-ion batteries, the innovation promises breakthrough

benefits that could displace other technologies. The Polymer ALD

technology could better protect battery electrode separators from

overheating and enable next-generation life-science tools, among other

applications.

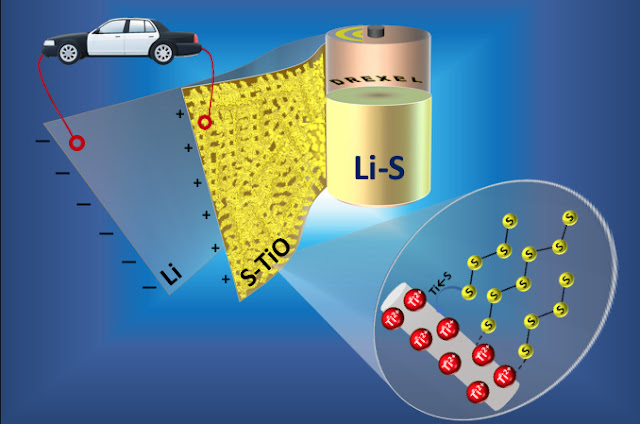

Another new patent2 is for Particle ALD use with super capacitor electrodes, and an in-license3

from CU Boulder for additional applications of ALD for batteries.

Together, they strengthen the company’s position in the energy storage

market. A further patent4 covers the use of an ALD method to

apply a ceramic coating to implantable medical devices. This expands ALD

Nano’s position in the life sciences industry. The company also filed a

patent5 internationally for its revolutionary Particle ALD

continuous flow reactor system. This allows for large-scale,

cost-effective Particle ALD advanced materials production.

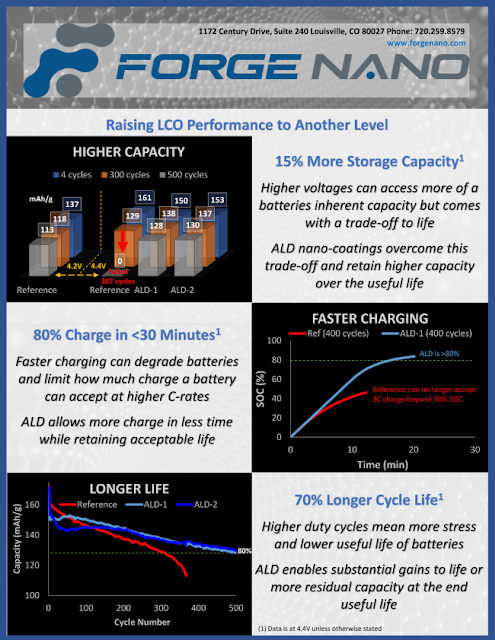

Enabling Innovation for Manufacturers of Lithium-Ion Batteries and LED Lighting

A standout 2016 highlight was the first commercial application of

Particle ALD for Cathode Active Materials (CAMs) used to produce

lithium-ion batteries. The breakthrough was achieved thanks to CU

Boulder’s extensive R&D and ALD Nano’s proprietary and robust IP

portfolio, coupled with the company’s strategic partnership with a

leading battery materials company. Particle ALD is the most effective

surface modification method available for CAMs. The ALD-enabled CAMs

will dramatically improve performance, extend cycle life and enhance the

safety of batteries for use in consumer electronics, electric vehicles

and grid storage.

Also in 2016, the company began commercial production of Particle ALD

phosphors for a Fortune Global 500 customer, following a multi-year

collaboration. The ALD advanced material significantly extends the

brightness lifetime for LED lights, while using a fraction of the

coating material required for other deposition methods.

Expanding Infrastructure to Address Growing Demand for ALD Solutions

With its accumulating IP, ALD Nano is expanding and deepening

engagements with customers. To support the momentum, the company doubled

manufacturing space at its headquarters in Colorado, and added new

reactors to increase production capacity. Headcount has also grown in

the last 12 months.

CEO Mike Masterson called 2016 a transformative year for ALD Nano:

“Our growth this year coincides with the consistently superior

performance of our ALD technology in many markets. This validates our

early vision and is now guiding our execution strategy to create ALD

advanced materials in partnership with leading sales channel partners

and customers. We’ll enter 2017 firmly positioned with differentiated

technology and expertise to help such companies achieve their technology

and cost-of-production goals. Our growth is a tribute to the steady

efforts of our team, and the extraordinary innovation contributed by

each individual.”

New ALD Nano Patents

1 US Patent 9,376,750

2 US Patent 9,406,449

3 US Patent 9,196,901

4 US Patent 9,279,120

5 US Application 62/175,964

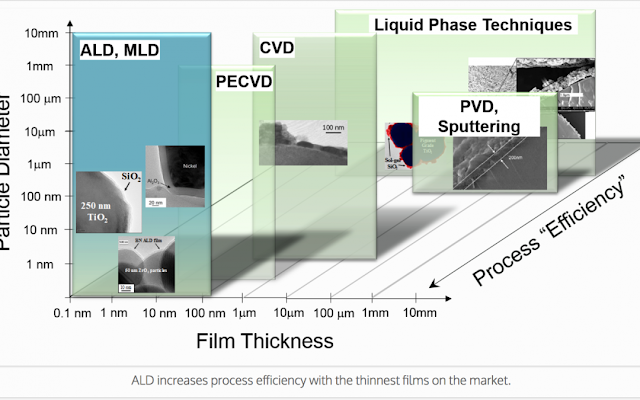

About ALD

ALD is the sequential vapor phase material deposition method that forms

chemically bonded, high-purity, conformal, ultra-thin films of

controlled nanometer thickness. ALD generates less waste than other

deposition techniques such as chemical vapor deposition, giving

customers a sustainable and cost-of-ownership edge, while helping to

reduce overall costs. The atomic level precision of ALD on particles,

polymers and other substrates enables new or better applications of

materials resulting in ALD advanced material solutions. Devices such as

consumer electronics are getting smaller and more complex, requiring

novel materials to solve critical issues for marketplace adoption.

About ALD NanoSolutions

ALD NanoSolutions (ALD Nano) is creating cost-effective advanced

materials that are transforming industries such as lighting, energy

storage, consumer electronics, life sciences, fuel catalysts, water

purification, sensors, and more. We’re the leader in Atomic Layer

Deposition (ALD) technology on particles, with broad IP covering

polymers and MEMS, as well. We partner with world-leading companies that

leverage our material designs and reactor systems to innovate products

that benefit consumers globally. For more than a decade, we have

commercialized innovative ALD technologies developed internally and

through research conducted at the University of Colorado Boulder. We’re

headquartered in Broomfield, Colorado.

%20(1).png)