LOUISVILLE, Colo., Sept. 5, 2019 /PRNewswire/ -- Mitsui Kinzoku-SBI Material Innovation Fund and LG Technology Ventures join in Forge Nano's Series A, bringing the total investment to date to $18M, up from Volkswagen's initial $10M investment announced in January 2019.

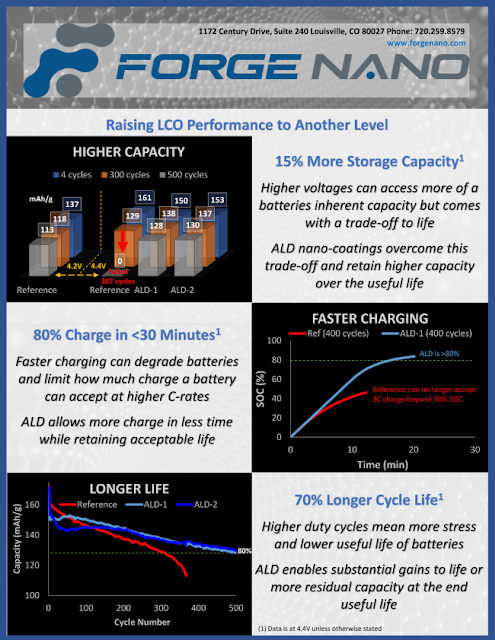

The investment will help to accelerate advanced materials for new battery technologies while also broadening applications for atomic-level nano-coatings into a diverse set of new markets. Forge Nano's technology paves the way for entirely new applications for nanoscale surface engineering. Atomic layer deposition (ALD) is an ultra-thin film deposition process that allows precision coatings that are the thickness of one atom to be deposited one layer at a time onto a surface. Forge Nano's ALD enabled core-shell battery materials have been demonstrated to improve the energy density, charge rate, cycle life, and safety of lithium-ion batteries as well as to enable next generation battery technologies.

Beyond batteries, ALD nano-coatings are enabling the next era of higher performance materials for catalysts, 3D printing, thermal fillers, separations and an array of other new market applications. Virtually any application using industrial powders that benefit from tuned surface properties but require precise, uniform and conformal coatings that are chemically bonded to the surface can now use ALD nano-coatings to unlock the next level of performance and value.

"Forge's proprietary nano-coating technology and high-throughput manufacturing processes will open the door for a new stage of high performance materials. A collaboration between Forge Nano and Mitsui Kinzoku will accelerate the production of high performance materials and provide our customers high value products in various market."

-Mitsui Kinzoku-SBI Material Innovation Fund

About Mitsui Kinzoku-SBI Material Innovation Fund: Mitsui Kinzoku-SBI Material Innovation Fund was jointly established in 2017 by Mitsui Kinzoku and SBI Investment. Its investment target is start-up companies with material technologies, material manufacturing and processing know-how which are each likely to generate a business synergy effect with Mitsui Kinzoku's business.

About LG Technology Ventures: LG Technology Ventures was established in 2018 and is the venture capital investment arm of the LG Group of South Korea. The LG Technology Ventures team consists of experienced investors, entrepreneurs, technologists, and industry domain experts. Currently, LG Technology Ventures is managing over $400 million of fund assets and invests in early-stage information technology, automotive, manufacturing, life-sciences, energy, and advanced materials companies.

About Forge Nano: Based in Louisville, Colo., Forge Nano is a global leader in surface engineering and precision nano-coating technology. Forge Nano's proprietary technology and manufacturing processes make angstrom-thick coatings fast, affordable and commercially viable for a wide range of materials, applications and industries. Forge Nano's suite of ALD products and services covers the full spectrum from lab-scale to pilot and commercial-scale manufacturing systems. For more information visit

www.ForgeNano.com

%20(1).png)