Dr. Sun’s

Nanomaterials & Energy Group at University of Western Ontario just published a very interesting paper on lithium iron phosphate by ALD for 3D solid state microbatteries in Advanced Materials.

Western Engineering professor Andy Sun, Canada Research Chair in Development of Nanomaterials for Clean Energy, is working toward increasing the performance of electric cars, by using lithium iron phosphate batteries (Professor charges toward better battery life).

Jian Liu, Mohammad N. Banis, Qian Sun, Andrew Lushington, Ruying Li, Tsun-Kong Sham, and Xueliang Sun

Adv. Mater. 2014, 26, 6472–6477

The atomic layer deposition technique is successfully applied to synthesize lithium iron phosphate using rationally designed surface reactions, as demonstrated for the first time by X. Sun and co-workers on page 6472. The lithium iron phosphate exhibits high power density, excellent rate capability, and ultra-long lifetime, showing great potential in vehicular lithium batteries and 3D all-solid-state microbatteries.

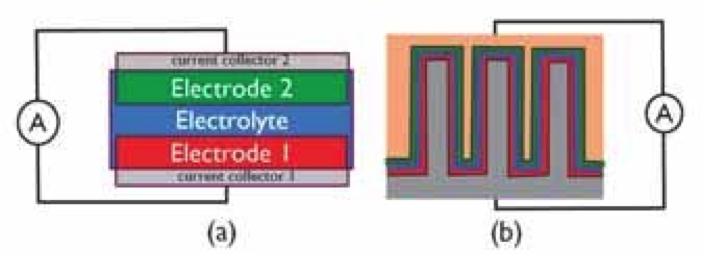

Herein, for the fi rst time, we develop an ALD approach to grow LiFePO 4*, as a typical example of quaternary LiMPO 4 cathode materials, by carefully tailoring the surface reactions that occur. Distinguished from solid-state reactions and solution chemistries, the ALD approach employs self-limiting, vapor-based surface reactions to deposit LiFePO 4 in a layer-bylayer manner (Fe 2 O 3 , PO x , and Li 2 O subcycles). In this way, the ALD approach permits precise control over the thickness and film composition of LiFePO 4 at the atomic level. This unprecedented accuracy promises a versatile design of nanostructured LiFePO4 on various types of substrates (in particular with high aspect ratio), and extends the employment of LiFePO4 to a broader range of applications, especially in 3D all-solid state microbatteries for autonomous micro-devices. Moreover, LiFePO 4 is deposited on carbon nanotubes (CNTs) by ALD to form LiFePO4 /CNT nanocomposite, aiming at breaking through the rate-capability bottleneck typically for pristine LiFePO4 . Excitingly, the LiFePO 4 /CNT electrode exhibits excellent rate capability, high power density, and ultra-long cycling lifetime, which are desirable properties for vehicular LIBs. Our work provides a new method for well-defined fabrication of high-powered.

* Amorphous LiFePO 4 at 300 °C with the use of ferrocene (FeCp2), ozone (O3), trimethylphosphate (TMPO), water (H2O), and lithium t -butoxide (LiOtBu) as precursors.

Here is an earlier review form 2012 :

Lithium-ion batteries (LIBs) are used widely in today's consumer electronics and offer great potential for hybrid electric vehicles (HEVs), plug-in HEVs, pure EVs, and also in smart grids as future energy-storage devices. However, many challenges must be addressed before these future applications of LIBs are realized, such as the energy and power density of LIBs, their cycle and calendar life, safety characteristics, and costs. Recently, a technique called atomic layer deposition (ALD) attracted great interest as a novel tool and approach for resolving these issues. In this article, recent advances in using ALD for LIB studies are thoroughly reviewed, covering two technical routes: 1) ALD for designing and synthesizing new LIB components, i.e., anodes, cathodes, and solid electrolytes, and; 2) ALD used in modifying electrode properties via surface coating. This review will hopefully stimulate more extensive and insightful studies on using ALD for developing high-performance LIBs.

%20(1).png)