Strem Chemicals’ offering of La-FMD is one of the most promising metal-amidinate ALD precursors for lanthanum (La) based ALD thin-films which are potentially strong candidates for high-k gate dielectric in the next generation of CMOS technology.

Rare earth elements have entered high volume manufacturing for advanced logic devices since the 32 nm node (IBM, Samsung and Globalfoundries – Chipworks 2010). Especially for Lanthanum (La) — the eponym of the lanthanide series in the periodic table has been implemented as a dopant in the high-k metal gate stack. Lanthanum oxide (La2O3, dielectric constant ~ 27), for example, has been explored for two decades as a high-k gate dielectric for the replacement of conventional silicon dioxide (SiO2) gate dielectric in the next generation transistors in logic as well as in dynamic random access memories (DRAMs).

Rare earth elements have entered high volume manufacturing for advanced logic devices since the 32 nm node (IBM, Samsung and Globalfoundries – Chipworks 2010). Especially for Lanthanum (La) — the eponym of the lanthanide series in the periodic table has been implemented as a dopant in the high-k metal gate stack. Lanthanum oxide (La2O3, dielectric constant ~ 27), for example, has been explored for two decades as a high-k gate dielectric for the replacement of conventional silicon dioxide (SiO2) gate dielectric in the next generation transistors in logic as well as in dynamic random access memories (DRAMs).

Keyword

segmentation of patent applications the last 20 years for Lanthanum and “Atomic

Layer Deposition” [Patbase search 15 November 2018]

Atomic layer deposition is the most promising method for growing ultra-thin-films of La based gate dielectrics and has therefore been under extensive research and filing of patent applications in the last 20 years. The R&D effort has been focused on fields relating to dielectric and high-k dielectric applications in the semiconductor industry (see keyword segmentation above). The atomic layer-by-layer film growth facilitated by self-limiting surface reactions in ALD provides atomically precise film-thickness control, good uniformity across a large area substrate, and excellent conformality in case of high aspect ratio structures like modern FinFETs and memory capacitor type pillar structures. However, to work flawlessly it requires the ALD precursors that have specific properties (LINK):

Atomic layer deposition is the most promising method for growing ultra-thin-films of La based gate dielectrics and has therefore been under extensive research and filing of patent applications in the last 20 years. The R&D effort has been focused on fields relating to dielectric and high-k dielectric applications in the semiconductor industry (see keyword segmentation above). The atomic layer-by-layer film growth facilitated by self-limiting surface reactions in ALD provides atomically precise film-thickness control, good uniformity across a large area substrate, and excellent conformality in case of high aspect ratio structures like modern FinFETs and memory capacitor type pillar structures. However, to work flawlessly it requires the ALD precursors that have specific properties (LINK):

1. Sufficiently volatile (at least ~ 0.1 Torr equilibrium vapor pressure at a temperature at which they do not decompose thermally).

2. Rapidly vaporizing and at a reproducible rate (conditions that are usually met for liquid precursors, but not for solids).

3. Not self-reacting or decomposing on the surface or in the gas phase (for self-terminating surface reactions).

4. Highly reactive with the other reactant previously attached to the surface, which results in relatively fast kinetics and thus lower ALD temperatures and cycle times.

5. Volatile byproducts that can be easily purged in order to prepare for the subsequent half-cycle.

6. Non-corrosive byproducts to prevent non-uniformities due to film etching and corrosion of the tool.

In 2007, Intel Corporation

incorporated HfO2 into high-k gate dielectric stack at 45 nm technology

node. However, pure HfO2 suffers from low-k interface layer problem

with Si, limiting lower equivalent oxide thickness (EOT) values. It also

readily crystallizes at temperatures as low as ~500°C. Therefore,

amorphous dielectrics with high thermal stability are still sought after

for no intrinsic defects (e.g. grain boundaries), provided they still

offer the advantages of HfO2, such as high dielectric constant, wide

band-gap, and low leakage current. Lanthanum-based ternary oxides,

such as lanthanum scandate (LaScO3) and lanthanum lutetium oxide

(LaLuO3), deposited by ALD process involving metal amidinate precursors

reportedly exhibit desirable structural and electrical properties. In

fact LaLuO3

is potentially the best amorphous phase gate dielectric with dielectric

constant k~32. It doesn’t form low-k interfacial layers with Si which

enables effective oxide thickness (EOT) values < 1 nm with

significantly low leakage current. Another factor contributing to the

low leakage current across ALD grown thin LaLuO3 gate dielectric is the

large band-offset (2.1 eV) with respect to Si; the symmetric conduction

and valence band offsets result into equal leakage currents in electron

driven NMOSFETs and hole driven PMOSFETs. It stays amorphous and doesn’t

form alloys with Si or Ge after respective source/drain activation

anneals.

As a very recent example of an actual high aspect ratio application on 300 mm wafers requiring all ALD precursor characteristics described above (1 to 6) we can see the paper that Imec presented at this famous IEDM conference, on using a LaSiOx layer as a dipole inserted in the HKMG stack. Imec succeeded in stacking the complete FinFET front end module on top of a "standard" bulk silicon FinFET module demonstrating also good threshold voltage tuning, reliability and low-temperature performance. Presumably it has most likely been deposited by an ALD process since it will have to conformally coat the fins and ensure precise thickness control and uniformity : IEDM2018 Paper #7.1, “First Demonstration of 3D Stacked FinFETs at a 45nm Fin Pitch and 110nm Gate Pitch Technology on 300mm Wafers,” A. Vandooren et al, Imec [LINK].

As in this case and many more, the stringent

qualifications for ALD precursors put them in the category of high quality

specialty chemicals — the performance or function specific materials or

molecules of choice. The deposited film properties are strongly influenced by

the physical and chemical properties of a single molecule or a formulated

mixture of molecules as well as its chemical composition. Therefore, it puts a

lot of pressure on the manufacturer and supplier of the high purity specialty

chemicals in terms of quality, purity, documentation procedures, customer

service etc.

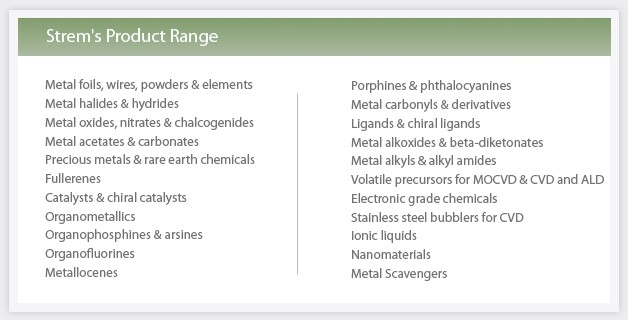

Strem Chemicals, Inc. headquartered in

Newburyport, Massachusetts, USA is an employee-owned fine chemicals supplier.

They’ve been manufacturing and marketing high-quality specialty chemicals for

more than half-a-century. Strem provides custom synthesis and FDA inspected

current good manufacturing practice (cGMP) services to its clients, which

include academia, industry, and government R&D labs. What helps to

distinguish Strem from the other chemicals suppliers is their commitment to

quality products. In fact, Strem has been listing color and form, a key quality

indicator, for every product since their first catalog. Strem is an ISO 9001:2015

Certified company. For additional

details about the more than 5,000 products offered by Strem, visit their

website, www.strem.com.

Tris(N,N'-di-i-propylformamidinato)lanthanum(III),

(99.999+%-La) La-FMD is one of the metal amidinate precursors in Strem’s

product catalog (catalog

number 57-1200, CAS number 1034537-36-4) for La ALD. The material is a white to

off-white powder. The chemical formula and the molecular weight of La-FMD are C21H45LaN6

and 520.53, respectively. Rohm

and Haas Electronic Materials LLC (subsequently Dow Chemical) reports La-FMD as the most

volatile La precursor known so far. The vapor pressure at a given temperature

imparted by La-FMD is higher than that by La(Cp)3 and La(thd)3.

Moreover, Roy

G. Gordon from Harvard University reports that the amidinate precursors are thermally

more stable than their amide counterparts because of the chelating amidinate

ligand and the absence of M-C bond. La amidinates are highly reactive with Si-H

bonds yielding much smaller surface saturation time and in turn quick

self-termination of ALD half-reaction; thus shortening the ALD cycle time. Also,

an excellent surface coverage is provided by La amidinate precursors on

Hydrogen terminated Si.

---

Promotional Blog for Strem Chemicals, Inc.

Researched, produced & written by BALD Engineering AB, Stockholm, 2019-01-23

Abhishekkumar Thakur, Jonas Sundqvist

www.baldengineering.com

%20(1).png)

?m impressed, I must say. Really rarely do I encounter a blog that?s both educative and entertaining, and let me tell you, you have hit the nail on the head. Your idea is outstanding; the issue is something that not enough people are speaking intelligently about. I am very happy that I stumbled across this in my search for something relating to this.Get Best Flame retardant textiles from Daletec.com in all over the world.

ReplyDeleteGreat job for publishing such a nice article. Your article isn’t only useful but it is additionally really informative. Thank you because you have been willing to share information with us. Buy Online Research Laboratory Chemicals USA

ReplyDeleteBlueberry Diesel. Grand Daddy Purp. Sour Tangie. Platinum OG. OG Kush. Cookies. Sherbert. LIME OG. Candyland. Durban Poison. Sour Diesel. OG Cookies

ReplyDeletebuy tko extracts online

tko extracts flavors

tko oil

buy stiiizy pods online

cereal carts for sale

buy stiiizy pods online

white runtz carts

Thanks for taking the time to discuss that, I feel strongly about this and so really like getting to know more on this kind of field. Do you mind updating your blog post with additional insight? It should be really useful for all of us. get cheap likes

ReplyDeleteUnlock the mysteries of your brain with the finest types of [url=https://www.psychedelicsonline-shop.com]magic mushrooms[/url] from [url]https://www.psychedelicsonline-shop.com[/url] – your onlin e source of [url=https://www.psychedelicsonline-shop.com]psychedelics drugs[/url] in USA.

ReplyDeleteThis gift of nature contains lemon tek, a [url=https://www.psychedelicsonline-shop.com]psychedelic[/url] compound with ordering [url=https://www.psychedelicsonline-shop.com]shrooms onlin[/url]e. [url=https://www.psychedelicsonline-shop.com] magic mushrooms[/url] onlin e which will alter your thoughts and emotions

alongside shrooms tea . You’ll experience a change in the world around you on how to order how to order ibogaine onlin e and [url=https://www.psychedelicsonline-shop.com] DMT[/url] when like halos around lights

and objects.

[url=https://www.psychedelicsonline-shop.com]psychedelic[/url]

[url=https://www.psychedelicsonline-shop.com]hallucinogens[/url]

[url=https://www.psychedelicsonline-shop.com]hallucinogenic[/url]

[url=https://www.psychedelicsonline-shop.com]psychedelics[/url]

[url=https://www.psychedelicsonline-shop.com]hallucinogenic drugs[/url]

[url=https://www.psychedelicsonline-shop.com]psychedelic drugs[/url]

[url=https://www.psychedelicsonline-shop.com]trippy websites[/url]

[url=https://www.psychedelicsonline-shop.com]lsd pills[/url]

[url=https://www.psychedelicsonline-shop.com]mollys[/url]

[url=https://www.psychedelicsonline-shop.com]buy mdma[/url]

[url=https://www.psychedelicsonline-shop.com]buy 1p-lsd[/url]

[url=https://www.psychedelicsonline-shop.com]buy magic mushroom[/url]

[url=https://www.psychedelicsonline-shop.com]buy magic mushrooms online[/url]

[url=https://www.psychedelicsonline-shop.com]magic mushrooms for sale[/url]

[url=https://www.psychedelicsonline-shop.com]tryptamine 5-meo dmt for sale[/url]

[url=https://www.psychedelicsonline-shop.com]mdma for sale[/url]

[url=https://www.psychedelicsonline-shop.com]dmt for sale[/url]

[url=https://www.psychedelicsonline-shop.com]3^4[/url]

[url=https://www.psychedelicsonline-shop.com]DMT[/url]

[url=https://www.psychedelicsonline-psilocybin mushrooms[/url]

Ecstatic Psychedelic is an international psychedelic shop which operates world wide.

ReplyDeleteOur main branch is based in USA where we carry out most of our operations. Delivery is done within the USA, CANADA and EUROPE with no hassles.

Visit our shop now and get best deals.

buy dmt online

buy mdma online

dmt trip

what is dmt

mushrooms

Ayahuasca

how to buy lsd online

buy Penis envy

where to buy Penis envy shrooms

penis envy mushrooms

golden teacher mushrooms

psychedelics

lsd

geek vape aegis legend 200w geekvape geekvape aegis legend

ReplyDeletegeekvape aegis solo geek vape aegis solo

voopoo drag mini kit

smok fetch

lost-vape orion plus

smok trinity alpha kit

giant vapes hexohm v2

smok mag 225w tc starter kit

smok-i priv 230w starter kit

smok mag grip 100w

smok mag baby 50w tc starter kit

ReplyDeletesmok mag baby 50w tc starter kit

smok g priv baby 85w starter kit

sigelei vape

smok g150 150w tc starter kit

smok alien 220w tc

sigelei sobra 198w tc starter kit

lions breath carts

ReplyDeletelions breath

big chief carts

big chief extracts

big chief smoker

glo extracts

ufo-extracts

tko extracts

tko edibles

This comment has been removed by the author.

ReplyDelete

ReplyDeletehttp://vapedank.net/Pax Era/

Pax Era

http://vapedank.net/product-category/pax-era-pods/

pax era pods

http://vapedank.net/product-category/smartbud/

smartbud

http://vapedank.net/product-category/smart-carts/

smart carts

http://vapedank.net/product-category/dankwoods/

dankwoods

http://vapedank.net/product-category/dank-vapes/

dank vapes

"Model: MZ00018£¬

ReplyDeleteCAS No.: 634-93-5 MF: C6H4Cl3N

EINECS No.: 211-219-8

Place of Origin: China

Type: indole derivatives

Grade Standard: High quality

Purity: 99.0% Min

Assay: 99%-101% Appearance: White powder

Solubility: Solubility in water

Water: 1.0% max

Sulfated Ash: 0.5% Max

Heavy Metals: 10 ppm Max

Test Method: H-NMR

Total Impurity: 0.5% Max

Application: indole" 2,4,6-trichloraniline £¬

I have read a few of the articles on your now, and I really like your style of blogging. I added it to my favorites blog site list and will be checking back soon. Please check out my site as well and let me know what you think.

ReplyDeleteGastroenterologist

very nice article and blog

ReplyDeletewvw-greatpeople.me

Great post, very nice content. Look forward for more articles like this.

ReplyDeleteGet quality bespoke packaging boxes printing , Custom Boxes UK, wholesale printed boxes for other CBD products and more for any product you need.

Stickers2go is the UK’s no 1 manufacturer of custom stickers printing and printed labels Order custom stickers and labels, in ANY shape and size, powered sticker printing for industry-leading quality. Order now to get discount on bespoke stickers printing

ReplyDeletePackagingPapa is the famous name of the packaging industry. The Custom Biscotti Packaging Boxes are designed by highly qualified manufacturers working for Packaging PAPA that is the most demanding company.

ReplyDeleteThe custom boxes are as extraordinary as they are unique and work wonders for businesses Packaging boxes is aiming at creating boxes from extremely biodegradable material. They're taking small stores to local domination, to national level brands to multi-national organization.Marijuana soap boxes

ReplyDeleteCustom boxes is the U.S manufacturer of and printed labels Order custom boxes and labels, in ANY shape and size, powered printing for industry-leading quality. Plus there's free delivery after you order, and our guarantee to beat any like-for-like quote for printed boxes and labels.

ReplyDeleteWhat might be said about food? A lot of our food is chemically treated with the goal that it is more productive to the organizations. tadalafil powder manufacturer

ReplyDeleteGreat post i must say and thanks for the information. Education is definitely a sticky subject. However, is still among the leading topics of our time. I appreciate your post and look forward to more. research chemical vendors

ReplyDeleteour Post is very informative. If you are looking for the new CBD Sample Boxes then you must get to our company site Custom Boxes Printing and check out new box styles to pack your products in them.

ReplyDeleteYour article is very beneficial for us.If you are looking for new boxes like vape subscription box then you can visit our website .Our boxes have good quality and you can order our boxes for packing your products.

ReplyDeleteThanks for the tips and information..i really appreciate it.. Research chemicals for sale

ReplyDeleteYour subject is very helpful for us.If you are looking for great quality boxes like rectangle gift boxes with Lids you can visit our website for this.Our boxes have their name in the world you can order them for packing your beautiful products.

ReplyDeleteCustom Printing Services co.uk. it is the best printing services and the follow my website new technology Buy Packaging Boxes Buy Packaging Boxes printing in the best works try the link open. thanks

ReplyDelete

ReplyDeleteI wish more authors of this type of conent would take the you did to research and write so well Write My Assignments For Me . I am very impressed with your vision and insight.

I definitely loved every little bit of it and i also have you book-marked to check out new information in your site.cosmetic packaging | cosmetic packaging

ReplyDeleteGreat post I like it very much keep up the good work.

ReplyDeleteUSA Custom Boxes

plain Gable boxes

This content is simply exciting and creative. I have been deciding on a institutional move and this has helped me with one aspect. Buy gelly tabs online

ReplyDelete

ReplyDeleteIn search of the best exotic medical marijuana strain online our cookies dispensary is here to serve your dailly needs . At cookiesconnected your satisfaction is our priority . Buy exotic cannabis at cookiesconnected

London Pound Cake

London Pound Cake Strain Online

Cereal Milk Strain

Cereal Milk Weed

Gushers Strain

Emerald Cut Strain

Jealousy Strain

Gary Payton Weed

Buy Gary Payton strain

Cheetah Piss

Buy Cheetah Piss Strain

Ice cream cake Strain

Buy Ice cream cake Weed Strain

Pink Runtz Strain

Pink Runtz Weed

Buy Pink Runtz Online

Gushers Weed Strain

White Runtz Strain

Buy White Runtz

Horchata Backpackboyz

Buy Zerbert Strain

Zerbert strain backpackboyz

Buy Black Cherry gelato Strain

Black cherry gelato backpackboyz

Apple Gelato Strain

Buy Apple Gelato Strain backpackboyz

Italian Ice Backpackboyz Strain

OOH lala strain

Buy OOH lala lemonnade strain

Pineapple Piss Strain

Pineapple Piss lemonade Strain

Lions Mane Strain

Cherry Pie Strain

Cake Mix Strain

The first thing that I must say is that you have a unique writing style. An interactive cum interesting style of explaining things. One thing is for sure that these tips are simply great!

ReplyDeleteanti theft backpack

Decent to be going to your web journal once more, it has been months for me. Well, this article that I've been waited for so long. I was searching for a good idea about powder coat oven which I found here. Thank you so much.

ReplyDeleteI feel really happy to have seen your webpage and look forward to so many more entertaining times reading here. Thanks once more for all the details.wholesale bottle neckers uk | wholesale bottle neckers uk

ReplyDeleteHi there, yeah this paragraph is in fact nice and I have learned lot of things from

ReplyDeleteit on the topic of blogging. thanks. acheter ketamine liquide

In this short tutorial we’ll cover the attributes you can use to add a destination anchor to your hyperlinks, tell the browser what to do with the link, and add semantic meaning to anchor elements for browsers and web crawlers to use.

ReplyDeleteread more:acheter kétamine

A good variety of sales employees from various drug manufacturing companies likewise see the drug shops to include additional to their knowledge bank. Prescription medicines become part of the life of the ever enduring humanity, with one condition or the various other. Generally, kétamine drogue

ReplyDeletethere are 2 types of medicines. Nonprescription medicines and prescription drugs. The difference in between both is that of treatment as well as regulation. Over the counter medicines are free offer for sale over the drug store’s counter. While the prescription medications can be sold just based on the direction of a registered competent physician. Neck and back pain medication is not the one that you can treat with the over-the-counter medications just. , drogue de l'amour

Nonprescription medicines and prescription drugs. The difference in between both is that of treatment as well as regulation. Over the counter medicines are free offer for sale over the drug store’s counter. While the prescription medications can be sold just based on the direction of a registered competent physician. Neck and back pain medication is not the one that you can treat with the over-the-counter medications just. md drogue

ReplyDeleteGet an opportunity to spend the night in Dubai's desert. It is an ideal escape from urban life because you will stay the evening in a vast desert camp underneath the blanket of stars. The safari trip continues with an exciting desert bashing drive and follows a variety of fun things.

ReplyDeleteAs the sun goes down, relax in the desert camp, which has a Bedouin feel to it, or relax by the flames until we represent you with a tasty BBQ meal with a delightful selection of salads and appetizers.Before actually leaving the Desert, you can enjoy the fantastic desert sun come up while eating your delicious breakfast. After an evening of dune bashing, camel riding, and significant photo shoots in the middle of a desert, a nightly camp in traditional Arab shelters in the wonderful desert, Abu Dhabi. Afterward, go to the camel farm for some fun. Stay in a traditional Arab camp with cushions and rugs, advanced lighting, and different men's and women's settings. Overnight desert safari

I am grateful to this blog site providing special as well as useful understanding concerning this subject.

ReplyDeleteTry to check my webpage on dr visiting card design

runtzhouse.com

ReplyDeletepurple runtz strain

jack herer leafly

chernobyl strain

purple runtz strain

gelato 45 strain

desido cookies strain

dankwoods blunt

blue skittles strain

sherblato strain

cake mix strain

dolato strain

ak-47 runtz

banana bread strain

sherblato

purple runtz strain

dosido cookies strain

sherblato leafly

gelato strain 45

runts weed

cake mix strain

ghost cookies strain

Codeine is a pain medication ketamine prix used to treat mild to normal pain. Visit our online store achat drogue Pharmacy to find codeine for sale online in the USA. Learn More: méphédrone achat

ReplyDeleteBuy tyres online at incredible prices at Etires.ae. Get Tires Installed at Your Doorstep or at a Installer Location Near You. best tyres shop | falken tyres Dubai

ReplyDeleteThe treating of the whole person, taking into account mental and social factors, rather than just the symptoms of a disease. Buy Cali Kush Online

ReplyDeleteWell I seriously appreciate the efforts you put in for making this article live. Thanks for this best Quotes of all time

ReplyDeleteAwesome and informative. appcreciated and comprehensive. waiting for the new one Tires Dubai

ReplyDeleteEnjoyed reading. appreciated. Top 10 Immigration Consultants

ReplyDeleteOur goal is to become one of the leading and trusted freight service providers in the United Arab Emirates. Najmat Al Insaf Cargo offers you flexible and professional freight services from the United Arab Emirates. Cargo To Pakistan Our well-trained specialists are your logistics consultants and accompany you from door to door. Dubai Freight Services and Dubai Port-to-Port Freight Services. We always strive for long-term relationships with our customers, service providers and our employees. In today's competitive marketplace, market reach is more important. We have the flexibility to offer you personalized services. Solutions according to your requirements, however demanding they may be.

ReplyDeleteERP Software Sharjah

ReplyDeleteWe welcome you for a fast presentation at the enterprise operations of SINA TYRES. Tyre Change Dubai More than years ago, SINA TYRES sustained its management as certainly considered one among the most important importers and exporters of Tires. Founded with inside the United Arab Emirates. The enterprise prolonged its operations in UAE. Dubai Tire Change The enterprise. has grown swiftly and these days we've got a huge worldwide purchaser community throughout the UAE

ReplyDeleteLogo Design Austin

ReplyDeleteThe logo should be in its completeness The logo end both the * to and the name of the college, in the face shown below, employment in the indicate ensign. The two elements are indissoluble and inalterable. No fresh elements may be added. The bespangle should never be manner on its own; nor should the name of the college be shown in the face and figure of the logo without the *. In title it is not dispensable to diversify the face of the logo or agitate the quota or maker of the logo in any moving

This is really a nice and informative, containing all information and also has a great impact on the new technology. Check it out here: Real Estate investment tips

ReplyDeletePurple Runtz is a leading digital agency in the niche of sports and entertainment, serving customers nationwide.

ReplyDeleteBest place to buy cheese cake pre-roll near me.

ReplyDeleteBest rolex hash in Fl Miami.

Where to order cookies strain online?

Best place to buy sherbet strain near me.

Where to order dankwoods online?

Best moorock strain near me.

Best place to order rick simpson oil online.

Where to buy absolutextracts cartridges online?

Click Here

ReplyDeleteClick Here

Click Here

Click Here

Click Here

Click Here

firewood for sale near me delivered

ReplyDeletefirewood supplier

firewood for sale

We provide a full range of Website Development, SEO, e-commerce, Web Design, Mobile apps, Web Application, and Digital Marketing in North Paravur, Kochi, Kerala.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteCourier Dunia is a Best International Courier, Cargo and Parcel Service Provider in Delhi-India. We Offer Competitive Shipping charges from India to USA, UK, Dubai, Canada, Australia, Europe and other countries.

ReplyDelete