- Kokusai is a small acquisition for Applied materials as compared to the previously failed mega-merger with Tokyo Electron

- Kokusai, which counts Samsung, SK Hynix, Toshiba, and Micron among its top customers, reported revenue of $1.24 billion as of March 2018.

- Kokusai’s batch wafer processing tools are less technology-intensive than Applied Materials’ single wafer tools, the recent focus on ultra-thin films has driven renewed interest in this group.

Wednesday, March 24, 2021

Applied Materials may kill $3.5B buy of Japanese ALD and CVD Furnace Company Kokusai over delayed approval by China

Friday, March 19, 2021

Picosun Group is among the 10 biggest patent applicants in Finland

Woxna AB in Sweden & Forge Nano USA to evaluate ALD coated graphite anode material for Lithium batteries

Thursday, March 18, 2021

AlixLabs AB launched ALE Pitch Splitting (APS) for the first time at ALD & ALE Ireland 2016

We did not want to steal the thunder from our good Irish friends and St. Patrick Day we wish you all a healthy recovery today and breakfast for Champions. Yesterday we remembered our trip to Dublin and launching our proprietary technology, APS - ALE Pitch Splitting, for the first time to a bigger audience. Since then a lot of things has happened at AlixLabs AB in Lund, Sweden:

- We received soft funding and invest support to found the company by LU Holding (LINK) - AlixLabs AB in Lund, Sweden operating out of IDEON Science park (LINK) and Lund Nano lab at Lund University

- We received SwedishVinnova grant for "Innovative startups" 93 startup-bolag får dela på 28 miljoner | Vinnova

- We hired our first Full-time employee Dr. Mohammad Karim, Principal Scientist (LINK)

- We signed an agreement to use the lab facilities of Sweden’s largest research environment for nanoscience and nanotechnology - Lund Nano Lab (LINK)

- We applied for an Additional 2.7 MSEK EU and National Swedish Soft co-funding in early 2021 and have additional 3 projects in the pipeline.

- We have started our 1st Investment round to close before Swedish Midsummer - please get in touch if you want a meeting! (jonas@alixlabs.com or LinkedIn: LINK)

ALE Pitch Splitting (APS) taking place at the Lund Nano Lab exhibition stand in the ALD Ireland 2016 Industry Exhibition.

Video from presentation invited given by Dr. Dmitry Suyatin LINK. Staff Engineer at Lund Nano Lab and CTO of AlixLabs AB and on the Scientific Committee of AVS ALE.

All photos above by Herr und Frau Dr. Knaut (C)2016 (https://www.katharinaknaut.com/index.php?seite=archiv&name=201608jonasald)

Get your ALD-VIP Coupon Code for The Critical Materials Conference CMC2021, 14-15 April 2021

Hey ALD Folks The Critical Materials Conference CMC2021, 14-15 April is coming up with some really powerful guest that will give you deep insights beyond the typical ALD conference offering on topics lie the semiconductor and global economics, Logic Foundry High Volume Manufacturing, Cost of Quality, Metrology and Big Data Machine Learning and Data Crunching for Plasma ALD.

ALD-VIP Coupon Code: Connect2Techcet-75

Carefully selected and invited talks for the ALD-community!- Keynote: Jeanne Yuen-Hum, Vice President of Manufacturing & Operations, and Director of Global Supply-Chain Quality & Reliability, Intel Corporation on "The Cost of Quality"

- G. Dan Hutcheson & Risto Puhakka, CEO & President, VLSI Research Post Pandemic – Semiconductor Industry Trends, Chaos or Order?

- David Thompson, PhD, Managing Director, Chemistry & Device Materials, Applied Materials Maximizing Chemical Utilization & Quality in Precursor Delivery

- Lian-Chen Chi 紀良臻, PhD, Nano-Materials Center Manager, TSMC Materials Quality vs. Technology Ing. Kutup Kurt, PhD, Head of Data Science, MERCK EMD/Versum Power of Hybrid Approach for Data-driven Process Optimization in Semiconductors Industry

- Hugh Gotts, PhD, International Fellow, Air Liquide ALD & CVD Precursors Metrology and Analytics Trends- Driving toward PPQ

- Tsuyoshi Moriya, PhD, MBA, VP Advanced Data Planning, Corporate Innovation Division, TEL The Impact of Machine Learning on Processes & Materials

As a bonus the 1st day we will have a virtual round table discussion on Materials Roadmaping in the industry. All participants are welcome to join.

Conference web for registration and agenda: https://cmcfabs.org/agenda-2021/

Tuesday, March 9, 2021

CN1 from South Korea showing all their ALD tools in a new video

Here is a nice new promotional video on CN1 ALD product offering showing a lot of detail into chambers and gas boxes for all you ALD geeks out there! CN1 was established in 2008 in Gyeonggi-do South Korea, and has a very broad ALD product portfolio including single water reactors, cluster tools and large batch ALD furnaces called Mega. Please find their complete offering here: LINK. According to the information in the video they have exported ALD tools across the globe to USA, Russia, Singapore, China and more.

ALD Stories podcast with Dr. Katja Väyrynen, Process Development Engineer at Beneq

Tutorial - ALD for energy conversion and storage applications, Prof. Adriana Creatore - Eindhoven University of technology

April 6-8 5th Area Selective Deposition Workshop (ASD 2021)

Key Deadlines: Early Registration Deadline: March 16, 2021 |

- Chris Bates, UC Santa Barbara, USA

- Fabio Grillo, ETH Zurich, Switzerland

- Ravi Kanjolia, EMD Electronics, USA

- Shashank Misra, Sandia National Labs, USA

- Ainhoa Romo Negreira, TEL, Belgium

- Tania Sandoval, Universidad Técnica, Chile

- Kavita Shah, Nova, USA

- Amy Walker, UT Dallas, USA

- Charles Wallace, Intel, USA

Saturday, March 6, 2021

ASM International confirms that ALD HKMG is in High Volume Manufacturing for DRAM - The 2nd Switch is on!

Benjamin Loh (ASMI CEO), answers on financial analyst question about if ASM has ALD tools in the field for DRAM high-k/metal gate:

"Mark thanks. So, of course, first of all, maybe let's talk about the memory parts of, in DRAM we started quite some time ago, we have been qualified for the high-k/metal gate in the DRAM periphery transistor. So right now, what you see for example, and what is called in the industry as high-performance DRAM. I think they are using our ALD for the mass for the high-volume manufacturing."

Thermal ALE of germanium rich SiGe by CU Boulder and ASM Microchemistry

Friday, March 5, 2021

EMD Performance Materials announces further investments of electronics business and new name: EMD Electronics

- New name reflects the product and service portfolio designed to enable the future of electronics in a data-driven world

- Investment into R&D and innovation centers in Tempe and Silicon Valley

- Patterning, deposition and spin-on dielectrics materials to make 3D NAND possible

- DSA – revolutionary way of building microchips of the future

- OLED for brighter, thinner, free-form displays

- Liquid crystals for electronic steerable antennas to bring connectivity to places currently not reachable

- eyerise ® liquid crystal for greener windows and innovative building architecture

Monday, March 1, 2021

Welcome to the RASIRC ALD Oxide Wizard

- Direct theoretical comparison between water and hydrogen peroxide

- Allows for rapid screening of possible precursors

- Allows for lower cost precursors to be used where previous water reactivity was too low

- Allows for visualization of precursors to better understand steric hindrance effects

Enter The RASIRC ALD Oxide Wizard HERE!

Sunday, February 28, 2021

WEBINAR - Longer-lasting implants with hermetic ALD coatings by Picosun

Improved reliability and functionality for electronic and orthopedic implants with Picosun’s ALD solutions

With the boom of digital and remote healthcare and the increasing life expectancy of people, there is a rapidly growing need for more and more advanced medical devices, both implanted and external. At the same time, recent advances in microelectronics and the constantly miniaturizing size of the components enable the design of highly sophisticated implanted devices that can be placed in the most sensitive areas of the body such as the brain, spine, heart, and eyes.

Picosun’s Atomic Layer Deposition (ALD) thin film coating technology offers a disruptive solution for implant manufacturers. Hermetic ALD encapsulation improves the reliability, functionality, and lifetime of electronic and orthopedic implants, potentially reducing the need for corrective or replacement surgeries. Also, cost savings can be achieved when the base materials of the implant can be e.g. stainless steels instead of noble or specialty metals.

Norwegian Morrow Batteries and Dutch startup Delft IMP have signed a JDA for ALD improved batteries

“We are applying ultra thin coatings on powder material and can produce these at scale with a unique technology originating from Delft University of Technology.” said Dr. Roderik Colen, CEO of Delft IMP. “It is a matter of time before breakthrough developments using ultra thin coatings become commercially available. The development of Morrow Industrialization Centre (MIC) provides us with a unique opportunity to demonstrate this at scale.”

Our spin-off @DelftIMP enters partnership with Morrow Batteries to jointly explore collaboration in using ultra-thin coating #batterytechnology to produce lower cost and more #sustainable #batteries in a Giga Factory.https://t.co/IES8g0aCwR pic.twitter.com/pcjLZbQkgz

— Ruud van Ommen (@JRvanOmmen) February 27, 2021

Saturday, February 27, 2021

2021 ISSCC - Plenary Session with Dr. Mark Liu, TSMC Chairman

Friday, February 26, 2021

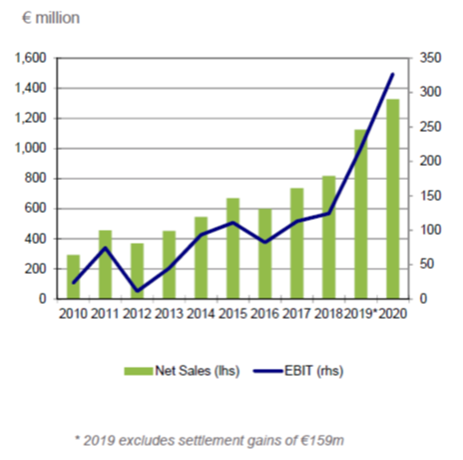

ASM International N.V. reports its 4Q/2020 operating results and the fourth consecutive year of double-digit growth

ASM International the leading supplier of single wafer ALD wafer processing equipment in the semiconductor industry reports that 2020 was the fourth consecutive year of double-digit growth.

- 4Q/2020 was driven by the logic/foundry segment, solid growth in China and a strong increase in spares & service business.

- ASM expects the single wafer ALD market to reach a size of approx. US$1.5 billion by ‘20-’21, and to grow substantially above that level in subsequent later years.

- Next ASM focus is on expanding their addressable market within the single wafer ALD space.

Source: 4Q/2020 Earings press release and investor presentation (LINK)

Area-selective MLD of nylon 6: Growth on carbon and inhibition on silica for a-carbon hardmask repair

Area-selective molecular layer deposition of nylon 6,2 polyamide: Growth on carbon and inhibition on silica

Journal of Vacuum Science & Technology A 39, 023204 (2021); https://doi.org/10.1116/6.0000769Marcel Junige and Steven M. George

Tech Insights Teardown: Samsung’s D1z DRAM with EUV Lithography

Reuters: SK Hynix signs five-year deal worth $4.3 billion with ASML to secure EUV scanners

Wednesday, February 24, 2021

The Nanotechnology Show October 13 - 14, 2021 Edison, New Jersey, USA

The Nanotechnology Show October 13 - 14, 2021 Edison, New Jersey, USA

Tuesday, February 23, 2021

Progress and future prospects of negative capacitance electronics: A materials perspective

1. Robust ferroelectricity at 5 nm thickness and below

2. Compatibility with CMOS technology

3. Thermal stability on silicon

4. Conformal deposition on 3D substrates

5. Large electronic bandgap and conduction band offset to Si

Progress and future prospects of negative capacitance electronics: A materials perspective

Thermal Atomic Layer Deposition of Gold: Mechanistic Insights, Nucleation, and Epitaxy

Thermal Atomic Layer Deposition of Gold: Mechanistic Insights, Nucleation, and Epitaxy

Pengfei Liu, Yuchen Zhang, Cong Liu, Jonathan D. Emery, Anusheela Das, Michael J. Bedzyk,Adam S. Hock*, and Alex B. F. Martinson*

ACS Appl. Mater. Interfaces 2021, XXXX, XXX, XXX-XXX

Thursday, February 18, 2021

Ferroelectric Field Effect Transistors (FeFETs) Bring Promise And Challenges

CEO interview: FMC’s Pourkeramati on roadmaps, turning away investors

https://www.eenewsanalog.com/news/ceo-interview-fmcs-pourkeramati-roadmaps-turning-away-investors

Friday, February 12, 2021

SIA Webinar: A Review of the 2020 Semiconductor Market and a Look to 2021

Safer medical devices with Picosun’s antimicrobial ALD coatings

“The aseptic properties of our ALD films are so excellent that they surpass even the strictest requirements of the medical implant industry."

Thursday, February 11, 2021

Imec Demonstrates 20nm Pitch Line/Space Resist Imaging with High-NA EUV Interference Lithography

Source: LINK

----------------------------

By Abhishekkumar Thakur

%20(1).png)