Phys.org reports: A team of

scientists from the U.S. Department of Energy's Brookhaven National Laboratory

and the University of Connecticut have developed a customizable nanomaterial

that combines metallic strength with a foam-like ability to compress and spring

back.

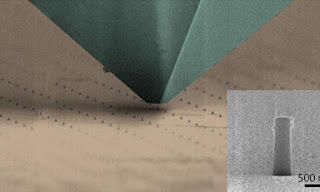

This scanning electron

micrograph (SEM) image shows the nanomechanical testing tip passing over

the arrays of custom-made nanopillars as it applies pressure to test

elasticity and energy storage potential. The inset shows the structure

of an individual hybrid nanopillar. Credit: Brookhaven National

Laboratory

Read more at: https://phys.org/news/2017-12-scientists-nanoscale-pillars-memory-foam.html#jCp

Read more at: https://phys.org/news/2017-12-scientists-nanoscale-pillars-memory-foam.html#jCp

This scanning electron

micrograph (SEM) image shows the nanomechanical testing tip passing over

the arrays of custom-made nanopillars as it applies pressure to test

elasticity and energy storage potential. The inset shows the structure

of an individual hybrid nanopillar. Credit: Brookhaven National

Laboratory

Read more at: https://phys.org/news/2017-12-scientists-nanoscale-pillars-memory-foam.html#jCp

Read more at: https://phys.org/news/2017-12-scientists-nanoscale-pillars-memory-foam.html#jCp

This scanning electron micrograph (SEM) image shows the nanomechanical testing tip passing over the arrays of custom-made nanopillars as it applies pressure to test elasticity and energy storage potential. The inset shows the structure of an individual hybrid nanopillar. Credit: Brookhaven National Laboratory

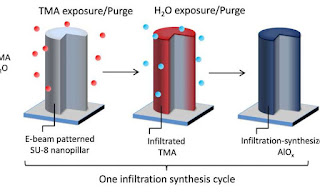

According to the supplemantary information The patterned SU-8 nanopillars were subjected to the AlOx infiltration synthesis at 85 °C using a commercial ALD system (Cambridge Nanotech Savannah S100). TMA (Sigma-Aldrich) was infiltrated into the polymer template for 5 min (vapor pressure <100 Torr), followed by N2 purging of the ALD chamber for 5 min (100 sccm). Then, water vapor was infiltrated into the polymer next for 5 min (pressure < 10 Torr), followed by N2 purging for 5 min, completing one synthesis cycle. A total of up to 16 cycles were applied.

This diagram shows the breakthrough synthesis process developed for these hybrid nanomaterials. First, electron-beam lithography carves the isolated nanopillars, then an aluminum vapor (TMA) infiltrates the pores in the structures, and finally exposure to water creates the final aluminum-oxide infused material. Credit: Brookhaven National Laboratory.

Please finde the abstract from Nanoletters below.

Read more

at: LINK

Ultrahigh Elastic Strain Energy Storage in Metal-Oxide-Infiltrated Patterned Hybrid Polymer Nanocomposites

Nano Lett., 2017, 17 (12), pp 7416–7423

DOI: 10.1021/acs.nanolett.7b03238 Modulus of resilience, the measure of a material’s ability to store and release elastic strain energy, is critical for realizing advanced mechanical actuation technologies in micro/nanoelectromechanical systems. In general, engineering the modulus of resilience is difficult because it requires asymmetrically increasing yield strength and Young’s modulus against their mutual scaling behavior. This task becomes further challenging if it needs to be carried out at the nanometer scale. Here, we demonstrate organic–inorganic hybrid composite nanopillars with one of the highest modulus of resilience per density by utilizing vapor-phase aluminum oxide infiltration in lithographically patterned negative photoresist SU-8. In situ nanomechanical measurements reveal a metal-like high yield strength (∼500 MPa) with an unusually low, foam-like Young’s modulus (∼7 GPa), a unique pairing that yields ultrahigh modulus of resilience, reaching up to ∼24 MJ/m3 as well as exceptional modulus of resilience per density of ∼13.4 kJ/kg, surpassing those of most engineering materials. The hybrid polymer nanocomposite features lightweight, ultrahigh tunable modulus of resilience and versatile nanoscale lithographic patternability with potential for application as nanomechanical components which require ultrahigh mechanical resilience and strength.

%20(1).png)