We are very happy to announce that have received a late news abstract from RASIRC out of San Diego, USA, for a presentation to be given at the EFDS Workshop "ALD for Industry" entitled “New ALD chemistries for low temperature

oxide and nitride films”. RASIRC is also sponsoring the workshop and will have a stand the the exhibition.

There are still room for some delegates to attend - so please consider to come to Dresden 17-18th of January and participate!

I have met Rasirc many times in Dresden and around the world. Here is a picture from Rasirc sponsoring and presenting the CMC Conference 2016 in Hillsboro USA organized by TECHCET, "Hydrazine as a Low Temperature

Nitride Source: Materials Challenges for High Volume Manufacturing " at

the event posing Dan Alvarez CTO and Jeff Spiegelman President and

Founder.

Link to ALD fro Industry Program HERE

#ALD4Industry (follow in Twitter)

In an European context ALD was invented independently twice in Europe

(Russia & Finland) and since the last 15 years Germany has grown to

become one of the strongest European markets for ALD in R&D,

chemicals, equipment and end users. Here, Dresden and Saxony is a unique

ALD hotspot due to a strong semiconductor and equipment industry.

As you can see we have managed to put together a fantastic program with

representatives from the European ALD Equipment Industry : Picosun

(FIN), Beneq (FIN), Sentech (GER), FHR Anlagenbau (GER), Encapsulix

(FRA), ASM International (NL) and special guests from the USA -

Ultratech CNT!

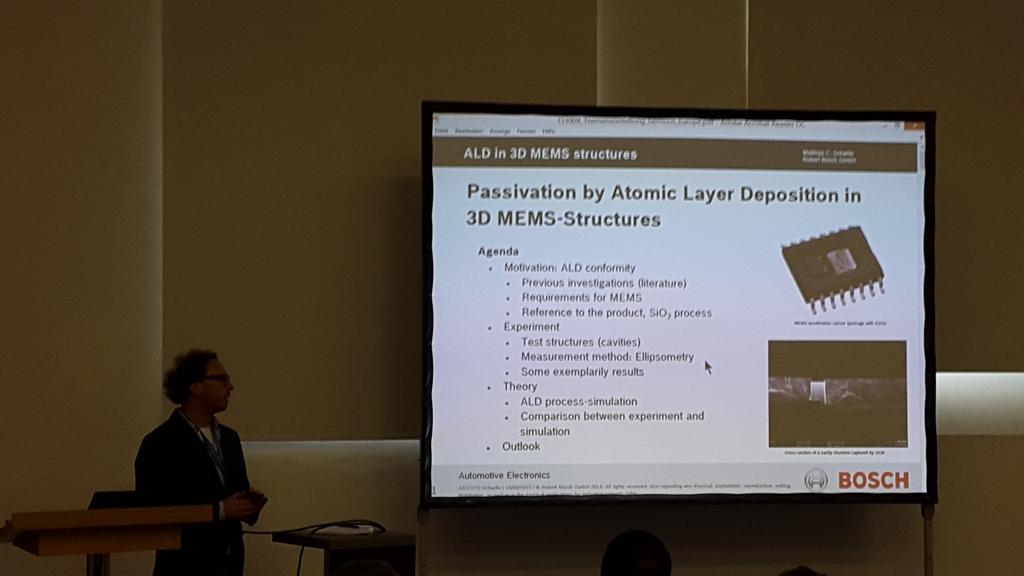

In addition, representatives from the chemical industry (Air Liquide),

customers (Robert Bosch) and research institutions from Germany

(Fraunhofer) and Finland (Aalto University and VTT Finland) will make

invited and contributing talks. Topics will cover industrialization of

ALD beyond the semiconductor industry:

▪ MEMS & Sensors ▪ Display ▪ Lightning ▪ Barriers ▪ Photovoltaics

Please visit EFDS for all information for this event and how to register HERE!

Platinum Sponsors:

Gold Sponsors:

%20(1).png)