TOKYO — December 13, 2016 — SEMI, the global industry association

representing more than 2,000 companies in the electronics manufacturing

supply chain, today reported that worldwide sales of new semiconductor

manufacturing equipment are projected to increase 8.7 percent to $39.7

billion in 2016, according to the SEMI Year-end Forecast, released today at the annual SEMICON Japan

exposition. In 2017, another 9.3 percent growth is expected, resulting

in a global semiconductor equipment market totaling $43.4 billion.

The SEMI Year-end Forecast predicts that wafer processing equipment, the largest product segment by dollar value, is anticipated to increase 8.2 percent in 2016 to total $31.2 billion. The assembly and packaging equipment segment is projected to grow by 14.6 percent to $2.9 billion in 2016 while semiconductor test equipment is forecast to increase by 16.0 percent, to a total of $3.9 billion this year.

For 2016, Taiwan and South Korea are projected to remain the largest spending regions, with China joining the top three for the first time. Rest of World (essentially Southeast Asia), will lead in growth with 87.7 percent, followed by China at 36.6 percent and Taiwan at 16.8 percent.

SEMI forecasts that in 2017, equipment sales in Europe will climb the most, 51.7 percent, to a total of $2.8 billion, following a 10.0 percent contraction in 2016. In 2017, Taiwan, Korea and China are forecast to remain the top three markets, with Taiwan maintaining the top spot even with a 9.2 percent decline to total $10.2 billion. Equipment sales to Korea are forecast at $9.7 billion, while equipment sales to China are expected to reach $7.0 billion.

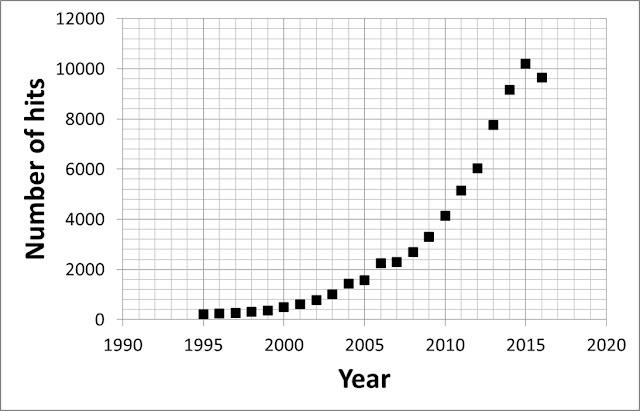

The following results are given in terms of market size in billions of U.S. dollars:

%20(1).png)