SEMICON Europa this year has turned out to be a major event for ALD and exciting nanoelectronic materials research. Here are photos taken from The ALD Day October 6th, 2015!

More details on this event you can find here : http://baldengineering.blogspot.de/2015/10/ald-ale-and-exciting-nanoelectronic.html

We are already looking forward to SEMICON Europa 2016 in Grenoble, France and to co-chair an ALD Sympoium there yet one more time!

SEMICON Europa ALD 2014, Grenoble : http://baldengineering.blogspot.de/2014/10/voila-3rd-ald-lab-dresden-symposium-at.html

More details on this event you can find here : http://baldengineering.blogspot.de/2015/10/ald-ale-and-exciting-nanoelectronic.html

We are already looking forward to SEMICON Europa 2016 in Grenoble, France and to co-chair an ALD Sympoium there yet one more time!

SEMICON Europa ALD 2014, Grenoble : http://baldengineering.blogspot.de/2014/10/voila-3rd-ald-lab-dresden-symposium-at.html

Columbus, Tuesday Oct 6, 13:45, ALD / ALE Sympoium of The ALD Lab Dresden, Messe Dreaden, Germany

Waiting for the ALD Storm!

Welcome

Prof. Johann W. Bartha, TU Dresden

In situ monitoring of Atomic Layer Deposition in porous materials

Martin Knaut, TU Dresden

Passivation of MEMS by Atomic Layer Deposition

Matthias Schwille, Robert Bosch

Symposium is full - please help me throw out a PVD guy

Growth Monitoring by XPS and LEIS Investigations of Ultrathin Copper Films Deposited by Atomic Layer Deposition

Dileep Dhakal, TU Chemnitz/FhG ENAS

High-k dielectrics by ALD for BEOL compatible MIM

Wenke Weinreich, FhG IPMS-CNT

ALD coatings for applications as permeation barrier and protective layer in fiber-reinforced materials

Mario Krug, FhG IKTS

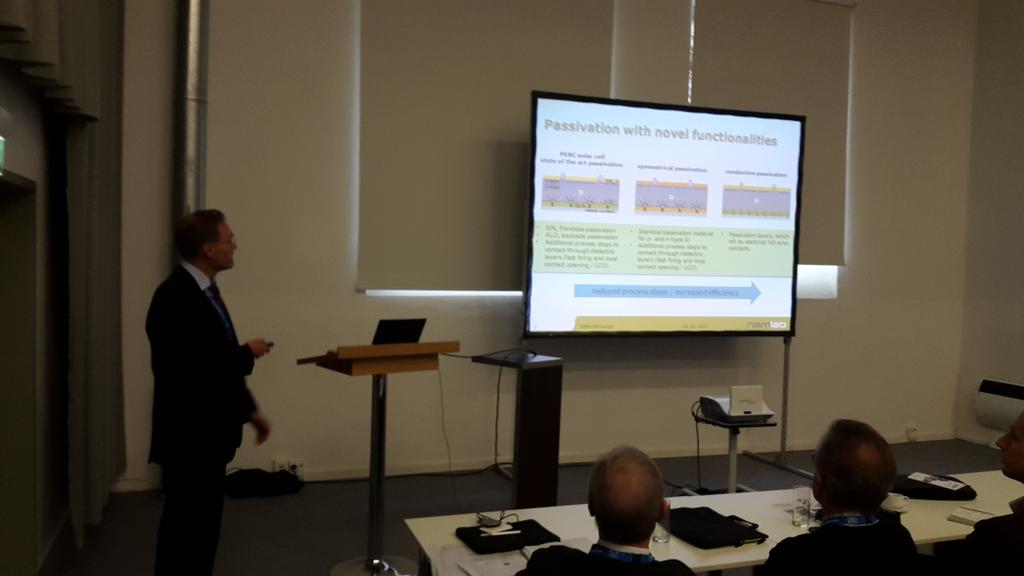

ALD for solar cell application

Ingo Dirnstorfer, NaMLab

Plasma enhanced ALD process for TiO2- and WO3- films

Alexander Strobel, FH Zwickau

Why do we need Atomic Layer Etching

Jonas Sundqvist, Lund University/TU Dresden

Spatial Atomic Layer Deposition and Atomic Layer Etching

Prof. Fred Roozeboom, TU Eindhoven / TNO Eindhoven

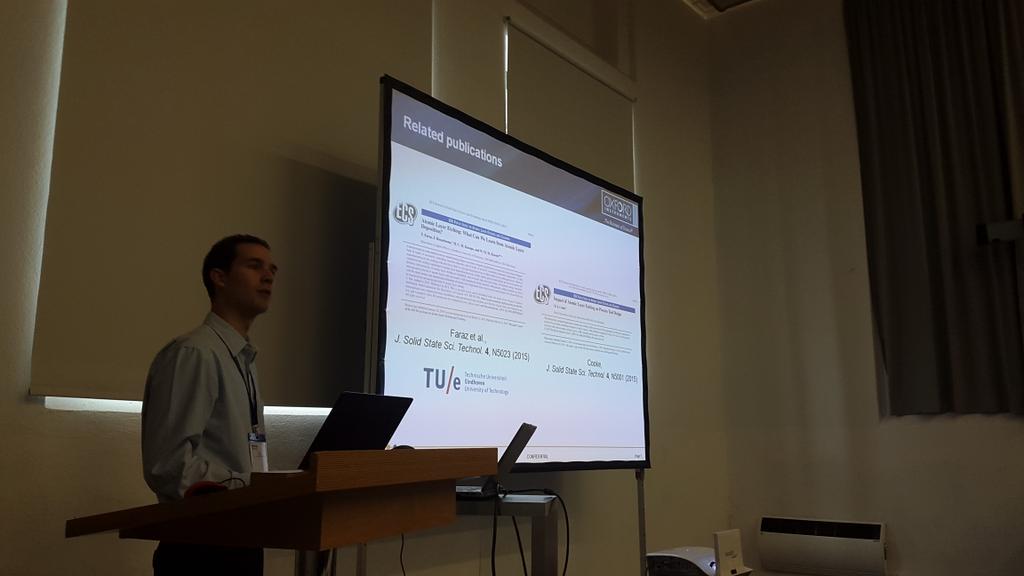

Atomic Layer Etching: What Can We Learn from Atomic Layer Deposition?

Harm Knoops, Oxford Instruments/TU Eindhoven

Hardmask and side wall protection during dry etching with plasma enhanced deposition during dry etching for ALE purposes

Stephan Wege, Plasway

Industrial High Throughput Atomic Layer Deposition Equipment and Process for OLED Encapsulation

Jacques Kools, Encapsulix

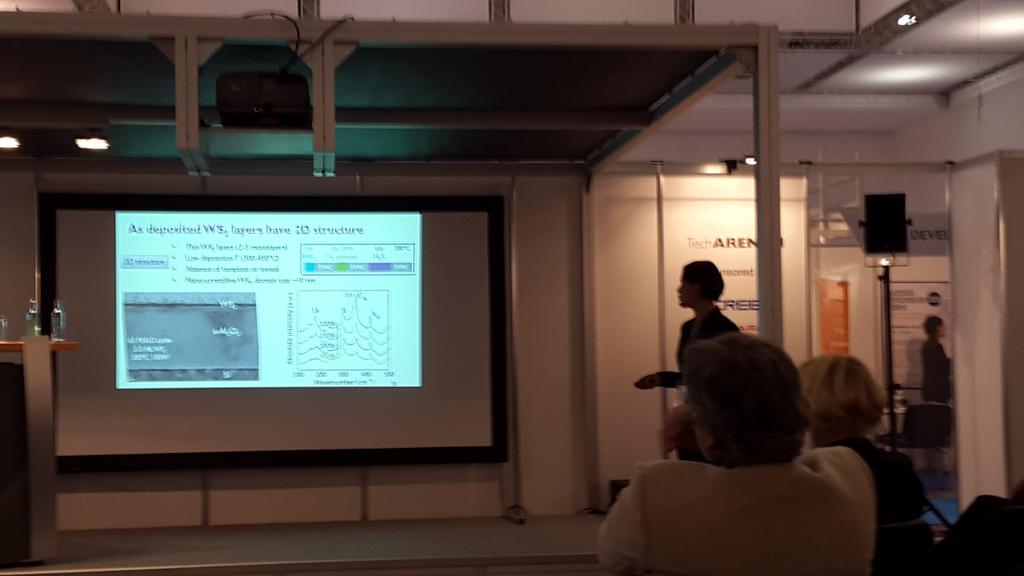

Monolayer controlled deposition of 2D transition metal dichalcogenides on large area substrates

Annelies Delabie, Imec

Selective Deposition as Enabler for Shrinking Device Dimensions

%20(1).png)