Company compares H2O2, H2O and O3 for dielectric ALD

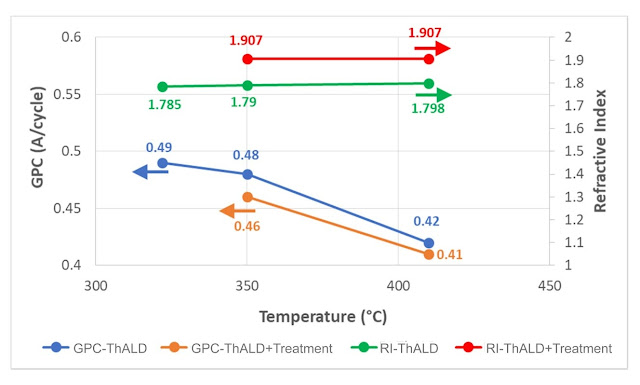

San Diego, Calif – June 20, 2019 – RASIRC will discuss test results that compare hydrogen peroxide gas, ozone, and water mixtures for TiO2 ALD film growth during EuroCVD 22 Baltic ALD 16 conference in Luxembourg on June 24-28. The company is an exhibitor at the highly esteemed conference. RASIRC President and Founder Jeffrey Spiegelman will present a poster entitled, “Comparison of Titanium Dioxide ALD Films Grown with Hydrogen Peroxide, Ozone, or Water” during poster session 2 on the evening of June 27th. The poster will address the benefits of H2O2 for TiO2 film and reveal best process conditions for TiO2 ALD growth.“Our research shows that H2O2 outperforms all other oxidants when growing low temperature TiO2 by ALD,” says Spiegelman. “This breakthrough provides a key solution for process engineers faced with the challenge of a low thermal budget.”

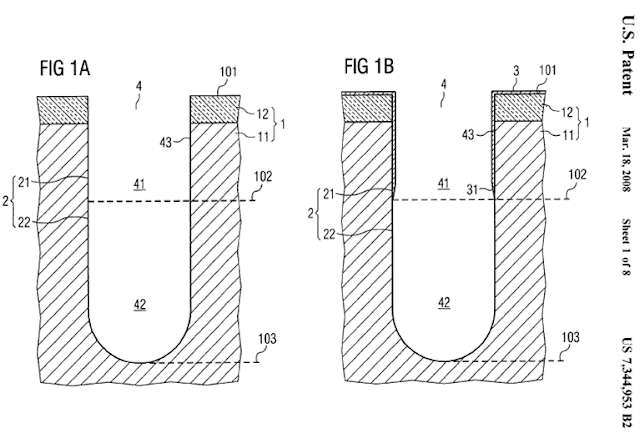

Professor Jiyoung Kim of University of Texas Dallas will also present a talk entitled, “Low temperature ALD of Silicon Nitride in Trench Structure: Comparing Hollow Cathode Plasma-Enhanced CVD and Thermal ALD with Hydrazine.” This work describes key advances for low temperature silicon nitride deposition utilizing RASIRC BRUTE® Hydrazine product.

EuroCVD 22-Baltic ALD 16 is part of the biennial series of European CVD conferences which started in Paris in 1977. It is one of the leading meetings for process and materials development in the world. The conference showcases forefront research addressing up-to-date challenges and state-of-the-art chemical processing from the gas phase (CVD, ALD, Energy-assisted CVD/ALD, MOVPE, RIE, ALE).

Spiegelman and additional RASIRC staff will be available throughout the event to discuss the RASIRC precursor chemistry product line-up, which includes the Peroxidizer®, BRUTE® Peroxide and more. Information about RASIRC products and company representatives will be available at the RASIRC exhibit located in Booth 6.

About RASIRC Products

RASIRC Peroxidizer provides high volumes of reactive H2O2/H2O mixtures for high throughput ALD. This reactive gas generator is ideal for roll-to-roll ALD coatings that require high speed deposition at reduced temperatures.

BRUTE Peroxide is a novel oxidant that improves nucleation density at film interfaces when compared to other oxidants. Surface functionalization is denser and initiation is faster using anhydrous hydrogen peroxide gas compared with alternatives. This enables better selectivity and less damage to metal surfaces in ASD processes.

BRUTE Hydrazine enables uniform nitride deposition for silicon and early transition metals at low temperature. BRUTE Hydrazine may also be used as an atomic hydrogen source, where metals such as Ru, Cu, and Co may be cleaned and reduced. Hydrazine gas is generated in situ and is virtually water free. Brute Hydrazine has been formulated for a relatively high flash point for safer handling.

Additional RASIRC products include the RainMaker® Humidification System (RHS) and the Hydrogen Peroxide Steamer (HPS). The RHS generates water vapor for oxidation applications and the HPS provides surface cleaning, preconditioning, gap fill curing, and residual carbon removal.

About RASIRC

RASIRC specializes in products that generate and deliver gas to fabrication processes. Each unit is a dynamic gas plant in a box — converting common liquid chemistries into safer and reliable gas flow for most processes. RASIRC technology delivers water vapor, hydrogen peroxide gas and hydrazine gas in controlled, repeatable concentrations. RASIRC gas delivery systems, humidifiers, and closed loop humidification systems are critical for many applications in semiconductor, photovoltaic, pharmaceutical, medical, biological, fuel cell, and power industries. Call 858-259-1220, email info@rasirc.com or visit http://www.rasirc.com.

#####

Contacts:

RASIRC

Jeffrey Spiegelman

Phone: 858-259-1220

E-mail: jeff@rasirc.com

%20(1).png)

Figure 3 - Novel delivery system for ultra-dry hydrazine vapor (left) and Vapor Pressure of BRUTE Hydrazine (right)

Figure 3 - Novel delivery system for ultra-dry hydrazine vapor (left) and Vapor Pressure of BRUTE Hydrazine (right)