|

Wednesday, April 10, 2019

In 2-Weeks: 2019 CMC Conference Highlights ALD/CVD Market and Technology Trends

Tuesday, April 9, 2019

Review Article: Atomic layer deposition of optoelectronic materials

@HelsinkiALD review on #Aldep of optoelectronic materials. Topics include insights on EL displays, III-Vs, PV applications and 2D TMDCs. Contributions from Profs. Leskelä and @MikkoRitala#openaccess #PapersMattinenhttps://t.co/g22ajQ8ABk— HelsinkiALD (@HelsinkiALD) April 9, 2019

Monday, April 8, 2019

USITC To Investigate Hanwha’s Claims

USITC To Investigate Hanwha’s Claims: Acting on Hanwha Q Cells' complaints of patent infringement in

the US, an administrative law judge of the USITC will initially

determine whether there has been a violation of Section 337 which will

then be reviewed by the commission.

Meaglows New Hollow Cathode Plasma Source Designs Provide Better Quality Films

The University of Connecticut group of Dr. Necmi Biyikli, with others, have recently published a paper (J. Vac. Sci. and Technol. A 37 (2019) 020927) where they were able to achieve good quality, highly stoichiometric AlN using hollow cathode plasma-assisted atomic layer deposition (HCPA-ALD) with film densities near bulk values. Because of the high radical flux from the source, significantly lower RF power was required to achieve this improvement in material quality compared to past experience, and shorter plasma on cycles could be used at these lower powers (20 seconds at 100 watts compared to 40 seconds at 300 watts).

Similar improvements in silicon nitride deposition were recently achieved by a team at the University of Texas, Dallas, where excellent quality, highly stoichiometric, high-density PA-ALD grown material was performed using one of our hollow cathode plasma sources (see, for instance, IEEE Electron Device Letters 39 (2018) 1195 ).

The image shows the University of Connecticut plasma source with ellipsometer ports and sample entry door. The 4″ diameter source was custom made for use with an Okyay Tech ALD system.

Meaglow’s hollow cathode plasma sources are widely used by the ALD Research Community as replacements for inductively coupled plasma (ICP) sources because there is less oxygen contamination when depositing non-oxide materials. However, these recent papers, by the University of Connecticut and the University of Texas, Dallas, illustrate advantages that may be far more important for the industry moving forward. Those being an extremely high radical flux, to the point where the ion signal (ion densities are similar to ICP sources) is swamped by the signal of radicals during optical emission spectroscopy measurements, and relatively low plasma damage (see our company white paper on hollow cathode sources). These result in quicker deposition times with potentially more stoichiometric, better quality material.

Saturday, April 6, 2019

Amtech Systems plans to divest its solar businesses

Amtech Systems, a manufacturer of capital equipment and consumables used in fabricating semiconductor devices, LEDs, SiC and silicon power chips ans well as solar cells, is planning to sell its solar businesses.

Amtech management and Board of Directors have decided to focus solely on growth opportunities in the Company’s semiconductor and SiC/LED polishing businesses and intend to sell the Company’s solar businesses, including its Tempress and SoLayTec subsidiaries.

Amtech’s J.S. Whang, Chairman and Chief Executive Officer, commented, “In November 2018 we announced that we had initiated a comprehensive review of our solar businesses. In a February update we noted thus far our review strongly indicates that our combined Semi and SiC/LED polishing business provide better markets for enhancing the value of Amtech Group. We have recently completed our assessment and conclude, along with Tempress and SoLayTec management, that significant investment is required to effectively compete in the changing solar industry. We therefore conclude Tempress and SoLayTec would be better positioned to capitalize on opportunities in the solar industry under new ownership.”

Source: Evertiq LINK

Thursday, April 4, 2019

Yes! The ALD/CVD Paper bot on Twitter is activated!

Yes! The ALD/CVD Paper bot on Twitter is activated! 68 Tweets (Papers) and counting.

@CVD_ALD_papers

I'm a paper bot surveying publications covering CVD & ALD! Operated by @DennisZyw93 & @Semajobe (Ruhr University). Adapted open-source code from @fxcoudert.

@CVD_ALD_papers

I'm a paper bot surveying publications covering CVD & ALD! Operated by @DennisZyw93 & @Semajobe (Ruhr University). Adapted open-source code from @fxcoudert.

Applied Optoelectronics orders MOCVD technology from AIXTRON

Photonics manufacturer expands production into growing laser business with multiple AIX 2800G4 systems

Herzogenrath/Germany, 2 April, 2019 – AIXTRON SE (FSE: AIXA), a worldwide leading provider of deposition equipment to the semiconductor industry, today announced the delivery of multiple AIX 2800G4 systems to US-based photonic maker Applied Optoelectronics, Inc. (AOI) which focuses on the design, development, and manufacturing of advanced optical devices, packaged optical components, optical subsystems, laser transmitters, and fiber optic transceivers. The delivered tools feature a 12x4-inch configuration.

Herzogenrath/Germany, 2 April, 2019 – AIXTRON SE (FSE: AIXA), a worldwide leading provider of deposition equipment to the semiconductor industry, today announced the delivery of multiple AIX 2800G4 systems to US-based photonic maker Applied Optoelectronics, Inc. (AOI) which focuses on the design, development, and manufacturing of advanced optical devices, packaged optical components, optical subsystems, laser transmitters, and fiber optic transceivers. The delivered tools feature a 12x4-inch configuration.

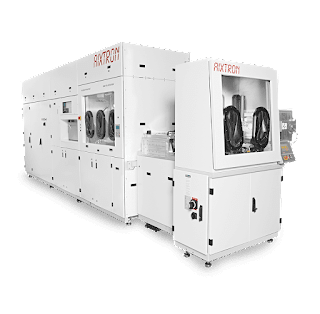

AIX 2800G4-TM

The AIX 2800G4 platform has established itself as the market-leading tool for high-volume production of vertical-cavity surface-emitting lasers (VCSEL) for 3D sensors and other diode lasers due to the matchless performance of the Planetary Reactor® concept with respect to thickness and wavelength uniformity control of epitaxial layers. The system provides incomparably high efficiency in handling the expensive chemicals used for MOCVD processes while delivering maximum production yield of premium level laser devices. In addition to the excellent reproducibility of each individual system, customers also appreciate the very good repeatability amongst systems.

Dr. Klaus Anselm, Vice President of Semiconductor Products at AOI, comments: "Following our good experience with AIXTRON systems in the past, we will also utilize the proven Planetary® technology from Germany for our production expansion. The AIX 2800G4 has convinced us in all test phases, so that we are now looking forward to use the system for launching volume production of our next generation of optoelectronic components."

"We are very pleased that AOI has added our market-leading AIX 2800G4 tool to its existing manufacturing equipment. A system that has acquired a reputation over the past few years as the tool of record for the production of high-quality laser devices in the semiconductor industry. We are looking forward to the collaboration with AOI," says Dr. Bernd Schulte, President of AIXTRON SE.

Dr. Klaus Anselm, Vice President of Semiconductor Products at AOI, comments: "Following our good experience with AIXTRON systems in the past, we will also utilize the proven Planetary® technology from Germany for our production expansion. The AIX 2800G4 has convinced us in all test phases, so that we are now looking forward to use the system for launching volume production of our next generation of optoelectronic components."

"We are very pleased that AOI has added our market-leading AIX 2800G4 tool to its existing manufacturing equipment. A system that has acquired a reputation over the past few years as the tool of record for the production of high-quality laser devices in the semiconductor industry. We are looking forward to the collaboration with AOI," says Dr. Bernd Schulte, President of AIXTRON SE.

Subscribe to:

Posts (Atom)

%20(1).png)