A topical workshop with focus on industrialization and commercialization of ALD for current and emerging markets

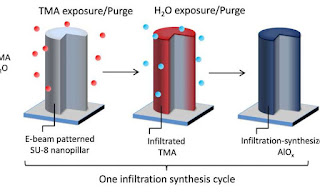

Atomic Layer Deposition (ALD) is used to deposit ultra-thin and highly

conformal films. ALD is unique in the sense that it employs

sequential self-limiting surface reactions for growth in the monolayer

thickness regime.

According to market estimates the equipment market

alone is currently at an annual revenue of US$ 1.5 - 1.7 billion (2017)

and it is expected to double in the next 4-5 years.

Dr. Harald Profijt Corporate R&D, ASM International, Netherlands (now at ASML) presenting "ALD technology for the continuation of Moore’s law" at ALD for Industry 2017. (Photo Dr. M. Knaut)

In a European context ALD was invented independently twice in Europe

(Russia & Finland) and since the last 15 years Germany has grown to

become one of the strongest European markets for ALD in R&D,

chemicals, equipment and end users. Here, Dresden and Saxony is a unique

ALD hotspot due to a strong semiconductor and equipment industry as well as a high concentration of Fraunhofer, Leibnitz, Helmholtz, Max Planck Institutes and the Technical University of Dresden.

Dr. Jacques Kools, Founder of Encapsulix S.A. explaining the secrets behind warp speed ALD (Photo Dr. M. Knaut)

The Event will focus on the current markets for ALD, besides the

leading edge semiconductor industry, applications in MEMS and Sensors,

Display, Lightning, Barriers and Photovoltaics will be addressed.

Confirmed speakers from: Globalfoundries (B. Hintze), Imec (Dr. S. van Elshocht), ASM Microchemistry (T. Blomberg), Picosun Oy, Beneq Oy (M. Söderlund), MKS Instruments (U. Meisner), OSRAM Opto Semiconductors GmbH, RASIRC (J. Spiegelman), University of Helsinki (Prof. M. Ritala), Fraunhofer THM (Prof. J. Heitmann)

Confirmed Tutorials: Fraunhofer IKTS (Dr. J. Sundqvist), Fraunhofer ENAS (Dr. J. Schuster), TU Dresden (Dr. M. Knaut), Fraunhofer IPMS (Dr. W. Weinreich), University of Linköping (Prof. H. Pedersen), Tyndall National Lab

Please visit the event web for the latest information:

LINK

Here is the event page from 2017:

LINK

The event is open for sponsoring and exhibition (contact: jonas.sundqvist@baldengineering.com)

%20(1).png)