Scientists

from École polytechnique fédérale de Lausanne (EPFL) in Switzerland has

reported a low cost system to split carbon dioxide to carbon monoxide

and oxygen using an ALD tin oxide catalyst on copper oxide nanowires.

The devis is working at a rather efficiency of 13.4%, which opens up new

paths to get rid of the man made CO2 that is currently heating up our

planet and causing extreme weather conditions everywhere - believe it

or not.

The

research comes out of the famous laboratory of Prof. Michael Grätzel at

EPFL, one of the worlds top 10 most cited chemists and most certainly

the most cited chemist from Dorfchemnitz in Saxony, Germany. One of his

most famous invention is the so called Gräzel cell - a dye-sensitized

solar cell, which is a low-cost version of thin film solar cells and he

was awarded the 2010 Millennium Technology Prize for this invention.

Michael Grätzel (born 11 May 1944, in Dorfchemnitz, Saxony, Germany) is

a professor at the École Polytechnique Fédérale de Lausanne where he

directs the Laboratory of Photonics and Interfaces [Wikipedia].

Using

Earth-abundant materials, EPFL scientists have built the first low-cost

system for splitting CO2 into CO, a reaction necessary for turning

renewable energy into fuel.

The future of

clean energy depends on our ability to efficiently store energy from

renewable sources and use it later. A popular way to do this is to

electrolyze carbon dioxide to carbon monoxide, which is then mixed with

hydrogen to produce liquid hydrocarbons like gasoline or kerosene that

can be used as fuel. However, we currently lack efficient and

Earth-abundant catalysts for the initial splitting of CO2 into CO and

oxygen, which makes the move into

renewable energy

expensive and prohibitive. EPFL scientists have now developed an

Earth-abundant catalyst based on copper-oxide nanowires modified with

tin oxide. The system can split CO2 with an efficiency of 13.4%. The work is published in

Nature Energy, and can help worldwide efforts to synthetically produce carbon-based fuels from CO2 and water.

Read more at:

https://phys.org/news/2017-06-low-cost-carbon-dioxide.html#jCpv

Using

Earth-abundant materials, EPFL scientists have built the first low-cost

system for splitting CO2 into CO, a reaction necessary for turning

renewable energy into fuel.

The future of

clean energy depends on our ability to efficiently store energy from

renewable sources and use it later. A popular way to do this is to

electrolyze carbon dioxide to carbon monoxide, which is then mixed with

hydrogen to produce liquid hydrocarbons like gasoline or kerosene that

can be used as fuel. However, we currently lack efficient and

Earth-abundant catalysts for the initial splitting of CO2 into CO and

oxygen, which makes the move into

renewable energy

expensive and prohibitive. EPFL scientists have now developed an

Earth-abundant catalyst based on copper-oxide nanowires modified with

tin oxide. The system can split CO2 with an efficiency of 13.4%. The work is published in

Nature Energy, and can help worldwide efforts to synthetically produce carbon-based fuels from CO2 and water.

Read more at:

https://phys.org/news/2017-06-low-cost-carbon-dioxide.html#jCp

Using

Earth-abundant materials, EPFL scientists have built the first low-cost

system for splitting CO2 into CO, a reaction necessary for turning

renewable energy into fuel.

The future of

clean energy depends on our ability to efficiently store energy from

renewable sources and use it later. A popular way to do this is to

electrolyze carbon dioxide to carbon monoxide, which is then mixed with

hydrogen to produce liquid hydrocarbons like gasoline or kerosene that

can be used as fuel. However, we currently lack efficient and

Earth-abundant catalysts for the initial splitting of CO2 into CO and

oxygen, which makes the move into

renewable energy

expensive and prohibitive. EPFL scientists have now developed an

Earth-abundant catalyst based on copper-oxide nanowires modified with

tin oxide. The system can split CO2 with an efficiency of 13.4%. The work is published in

Nature Energy, and can help worldwide efforts to synthetically produce carbon-based fuels from CO2 and water.

Read more at:

https://phys.org/news/2017-06-low-cost-carbon-dioxide.html#jCp

Using

Earth-abundant materials, EPFL scientists have built the first low-cost

system for splitting CO2 into CO, a reaction necessary for turning

renewable energy into fuel.

The future of

clean energy depends on our ability to efficiently store energy from

renewable sources and use it later. A popular way to do this is to

electrolyze carbon dioxide to carbon monoxide, which is then mixed with

hydrogen to produce liquid hydrocarbons like gasoline or kerosene that

can be used as fuel. However, we currently lack efficient and

Earth-abundant catalysts for the initial splitting of CO2 into CO and

oxygen, which makes the move into

renewable energy

expensive and prohibitive. EPFL scientists have now developed an

Earth-abundant catalyst based on copper-oxide nanowires modified with

tin oxide. The system can split CO2 with an efficiency of 13.4%. The work is published in

Nature Energy, and can help worldwide efforts to synthetically produce carbon-based fuels from CO2 and water.

Read more at:

https://phys.org/news/2017-06-low-cost-carbon-dioxide.html#jCp

Using

Earth-abundant materials, EPFL scientists have built the first low-cost

system for splitting CO2 into CO, a reaction necessary for turning

renewable energy into fuel.

The future of

clean energy depends on our ability to efficiently store energy from

renewable sources and use it later. A popular way to do this is to

electrolyze carbon dioxide to carbon monoxide, which is then mixed with

hydrogen to produce liquid hydrocarbons like gasoline or kerosene that

can be used as fuel. However, we currently lack efficient and

Earth-abundant catalysts for the initial splitting of CO2 into CO and

oxygen, which makes the move into

renewable energy

expensive and prohibitive. EPFL scientists have now developed an

Earth-abundant catalyst based on copper-oxide nanowires modified with

tin oxide. The system can split CO2 with an efficiency of 13.4%. The work is published in

Nature Energy, and can help worldwide efforts to synthetically produce carbon-based fuels from CO2 and water.

Read more at:

https://phys.org/news/2017-06-low-cost-carbon-dioxide.html#jCp

Below the abstract and the link to the Nature Energy publication

Solar conversion of CO2 to CO using Earth-abundant electrocatalysts prepared by atomic layer modification of CuO

Marcel

Schreier, Florent Héroguel, Ludmilla Steier, Shahzada Ahmad, Jeremy S.

Luterbacher, Matthew T. Mayer, Jingshan Luo & Michael Grätzel

Nature Energy 2, Article number: 17087 (2017)

doi:10.1038/nenergy.2017.87

Abstract:

The solar-driven electrochemical reduction of CO2 to fuels and

chemicals provides a promising way for closing the anthropogenic carbon

cycle. However, the lack of selective and Earth-abundant catalysts able

to achieve the desired transformation reactions in an aqueous matrix

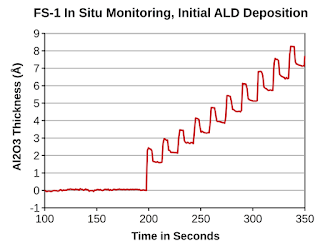

presents a substantial impediment as of today. Here we introduce atomic

layer deposition of SnO2 on CuO nanowires as a means for changing the

wide product distribution of CuO-derived CO2 reduction electrocatalysts

to yield predominantly CO. The activity of this catalyst towards oxygen

evolution enables us to use it both as the cathode and anode for

complete CO2 electrolysis. In the resulting device, the electrodes are

separated by a bipolar membrane, allowing each half-reaction to run in

its optimal electrolyte environment. Using a GaInP/GaInAs/Ge

photovoltaic we achieve the solar-driven splitting of CO2 into CO and

oxygen with a bifunctional, sustainable and all Earth-abundant system at

an efficiency of 13.4%

%20(1).png)