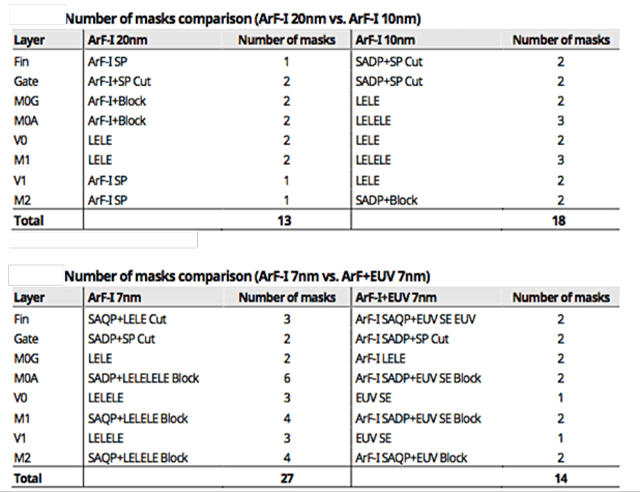

Semi Analysis recently published a deeper dive into of Directed Self Assembly (DSA) and prospects of Intel using it at their 14A node (Link below). Intel's latest efforts in semiconductor manufacturing have brought considerable attention to its 18A node, yet it's the 14A node that is most important according to the analysis for the success of Intel Foundry's IDM 2.0 strategy. While the industry watches the ongoing discussions around the merits of TSMC's N2 and Intel’s 18A technologies, Intel is quietly setting a foundational stage with its 14A node, aiming to solidify customer trust and secure critical, high-value chip projects for the future. A key element in Intel's strategy may be the adoption of DSA that could significantly reduce lithography costs. DSA utilizes the self-organizing properties of block copolymers (BCPs) that assemble into predetermined patterns when guided by an underlying template. This approach promises to lower the doses required in extreme ultraviolet (EUV) lithography, allowing for more efficient patterning at reduced costs.

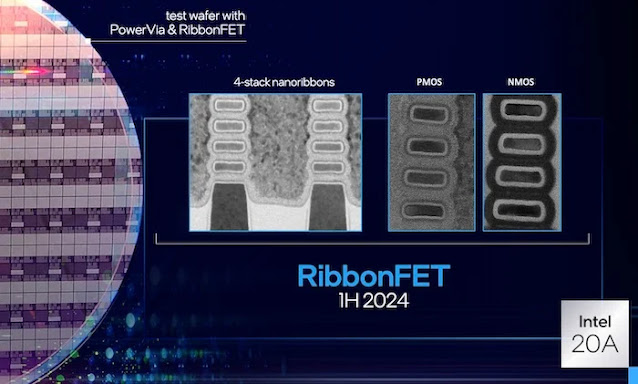

It is well known that Intel plans to be the first major company to implement ASML’s high-NA EUV lithography scanners in high volume, despite the higher costs associated with single exposure high-NA systems compared to low-NA double patterning. It was also recently reported on X and other places that ASML is delivering a High-NA System to another player. SemiAnalysis argues that, the economic challenge posed by high-NA technology is addressed through the integration of DSA, which can improve the final pattern quality and dramatically reduce the necessary dose, thus potentially making high-NA economically more viable.

The benefits of DSA are significant:

- The ability to produce finer features with lower line edge roughness and increased throughput, thanks to its ability to heal discrepancies in the EUV guide patterns.

- Substantial cost savings and improved yield, especially for layers critical to the performance of advanced logic chips (bigger dies like AI accelerators).

However, DSA's integration into a commercial manufacturing environment is not without risks. The risks associated with Intel's adoption of DSA include:

- The primary risk with any new patterning technology is defectivity, for DSA it is linked to the chemical purity of the block copolymers (BCP). Synthesizing BCP to extremely high purities is challenging, and any inhomogeneity directly impacts the critical dimension (CD), leading to defects. Trace metals need to be below 10 parts-per-trillion, and filtering out organic impurities is difficult, impacting the viability of DSA for mass production. My assessment - Expect this to come from a MERCK or a Japanese chemical vendor.

- DSA is inherently limited to producing 1D line/space patterns or contact hole arrays, restricted to a single pitch per layer. This complicates the integration with other process technologies that might require more diverse patterning capabilities. However, these issues have potential solutions similar to those used in multi-patterning schemes.

- Despite the theoretical benefits and recent advances in DSA, it remains largely untested in high-volume, leading-edge manufacturing. Intel is pioneering the use in high-NA scenarios, but the broader adoption across the industry, including by competitors like TSMC who are also developing DSA, remains uncertain.

Source: Intel’s 14A Magic Bullet: Directed Self-Assembly (DSA) (semianalysis.com)

So let´s do the Patbase Test - how does this hold out if we dig into historical and current patent filing by the suspects!

Yes indeed, we have seen much increased filing the past decade or so representing a typical hype cycle. The hype cycle is a model developed by Gartner that describes the progression of a technology from inception to widespread adoption and maturity. It typically consists of five phases: the Technology Trigger, Peak of Inflated Expectations, Trough of Disillusionment, Slope of Enlightenment, and Plateau of Productivity. So for DSA in semiconductor manufacturing, the technology first garnered attention when its potential applications in advanced lithography were identified (2000-2010), marking the Technology Trigger. Interest surged about 2011, leading to a Peak of Inflated Expectations around 2016/2017, evidenced by a spike in patent filings as companies raced to capitalize on the emerging technology. However, as practical and economic challenges such as defectivity and integration complexities became evident, the enthusiasm waned, and DSA entered the Trough of Disillusionment. During this phase, the technology's limitations led to a decline in interest as initial expectations were not met. Over time, as more sustainable applications and improvements are developed, DSA may progress into the Slope of Enlightenment, where understanding and optimization occur as described in the assessment by SemiAnalysis, before finally reaching the Plateau of Productivity in the years to come, where it becomes a standard part of semiconductor manufacturing processes. This progression through the hype cycle reflects the typical maturation path of innovative technologies in the industry. Please note that there is a delay in patent filing data of up to 18 months so 2022, 2023 and 2024 are not complete yet.

Patent filing since 2000 in DSA (Patbase, 2024-04-19)

2. Yes, Intel is actively filing DSA patents and in the lead, and so is TSMC, along with other key players in the ecosystem. Over the past decade, the pattern of DSA patent filings has been quite revealing. Initially, GlobalFoundries and IBM in Upstate New York were early filers. GlobalFoundries ceased their filings around the time they decided not to pursue 7 nm and nodes below. IBM also stopped filing after completing their 2 nm demonstration on 300 mm wafers in 2021. Main contenders Intel and TSMC have been consistently filing DSA patents throughout the hype cycle and have continued to do so. Notably, there has been a clear acceleration in Intel's patent filings since 2019, although there was a slight drop during the COVID-19 lockdowns. Looking at chemical suppliers, Merck has taken the lead, with increased filings beginning in parallel with Intel from 2019 onwards, and accelerating until today. Other suppliers such as JSR, Shin-Etsu, and Brewer Science are also active in the DSA space. In the segment of wafer equipment OEMs, Tokyo Electron and SCREEN have been dominant. However, SCREEN appears to have recently exited the game.

%20(1).png)